Granuladora húmeda Grand de alto rendimiento | Mezcladora-granuladora serie HLSG

Los 10 principales fabricantes europeos de máquinas de llenado de cápsulas semiautomáticas

Navigating the European Market: A Guide to the Top 10 Semi-Automatic Capsule Filling Machine Manufacturers

In the ever-evolving landscape of pharmaceutical and nutraceutical production, the efficiency and reliability of your equipment are paramount. The capsule filling machine, a cornerstone of this industry, plays a pivotal role in ensuring that products are manufactured to the highest standards of quality and precision. For small to medium-sized enterprises, research and development labs, and companies scaling up their production, the semi-automatic capsule filling machine offers the perfect balance of automation, flexibility, and cost-effectiveness.

The European market, renowned for its engineering excellence and stringent quality standards, is home to some of the world's most reputable pharmaceutical machinery manufacturers. This blog post will delve into the top 10 semi-automatic capsule filling machine manufacturers in Europe, providing an in-depth look at their offerings. We will also explore how these machines can be integrated into a complete production line with ancillary equipment, such as capsule polishers, blister packaging machines, and cartoning machines, to create a seamless workflow from filling to final packaging. While our primary focus is on European leaders, we will also feature a noteworthy international contender that is making significant waves in the market due to its exceptional value and performance.

The Growing Demand for Semi-Automatic Solutions

The global demand for pharmaceuticals and health supplements is on a continuous upward trajectory. This has led to a surge in the need for efficient and scalable manufacturing solutions. Semi-automatic capsule filling machines have emerged as a popular choice for businesses that require a higher output than manual fillers but are not yet ready for the significant investment of a fully automatic line. These machines automate the most critical and repetitive tasks of capsule filling, such as powder dosing and capsule closing, while still allowing for manual oversight and control. This blend of automation and manual intervention makes them ideal for producing smaller batches, conducting clinical trials, and handling a variety of products with different formulations.

Top 10 Semi-Automatic Capsule Filling Machine Manufacturers in Europe (and a notable contender)

Here, we present our curated list of the top manufacturers, recognized for their innovation, quality, and customer support.

1. Syntegon Technology (Germany)

Formerly Bosch Packaging Technology, Syntegon has a long-standing reputation for producing high-quality, reliable, and technologically advanced pharmaceutical processing and packaging machinery. Their German engineering is evident in the precision and durability of their equipment.

Key Features of Syntegon's Semi-Automatic Fillers:

- Precision Dosing: Syntegon's machines are known for their highly accurate dosing systems, minimizing product waste and ensuring consistent capsule weight.

- Flexibilidad: Their semi-automatic models are designed to handle a wide range of capsule sizes and filling materials, including powders, pellets, and granules.

- Interfaz fácil de usar: Equipped with intuitive touch-screen controls, these machines are easy to operate, reducing the need for extensive operator training.

- Cumplimiento: All Syntegon machines are designed to meet the stringent cGMP (current Good Manufacturing Practices) standards required in the pharmaceutical industry.

2. Máquina de paquetes de abuelos (International Contender)

While not based in Europe, Grandpackmachine has earned its place on this list as a formidable international competitor, offering an exceptional price-to-performance ratio that is capturing the attention of businesses worldwide. Their upgraded CGN208-D1 model is a testament to their commitment to providing high-quality, user-friendly, and efficient capsule filling solutions.

El upgraded CGN208-D1 semi-automatic capsule filling machine is an evolution of the older DTJ-C model, re-engineered with the user experience at its core. This machine is specifically designed for clients with medium-output requirements who need a reliable workhorse that can operate for extended periods without the need for preventative maintenance for up to 18 months of normal production.

Superior Performance and Innovative Design:

- Enhanced Stability and Reduced Noise: The CGN208-D1 features a new, patented capsule sowing device with an independent support and separate power system, resulting in more stable and quieter operation.

- Control de precisión: A patented linear rail system for the capsule control switch allows for precise and convenient adjustments.

- Ease of Cleaning: The design includes features that facilitate quick and thorough cleaning, such as an independently opening front plate on the small capsule hopper and a powder-sieving capsule output mechanism that can be fully disassembled and reassembled in under 30 seconds.

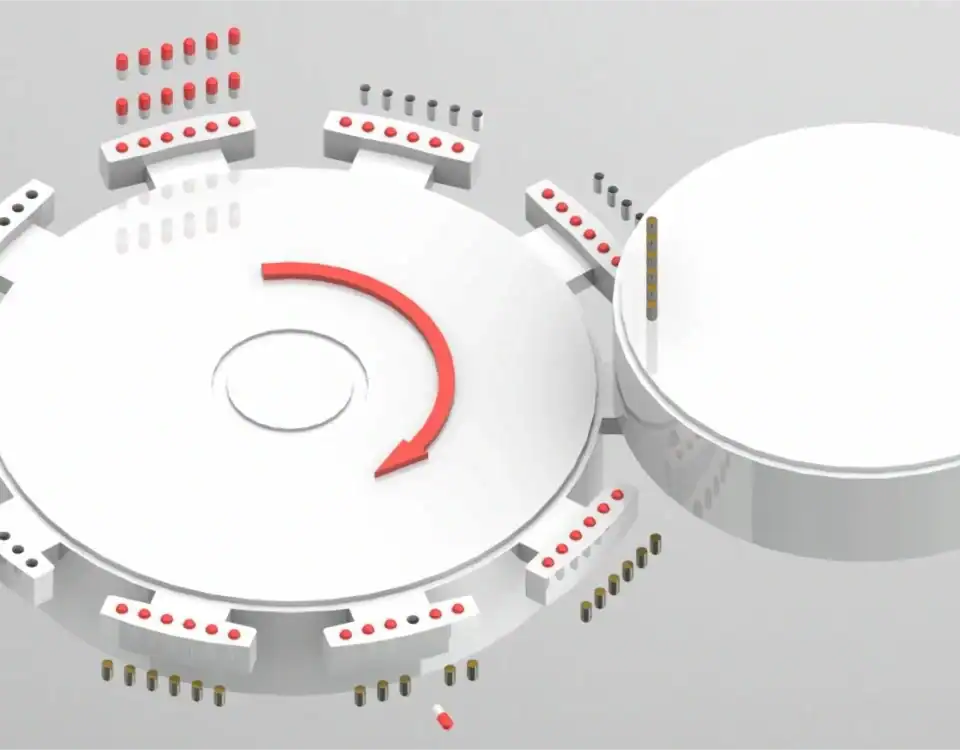

- High-Speed Stability: The capsule disc operates with a linked motion, avoiding the start-stop jolts of older intermittent systems and enabling stable, high-speed performance.

- Efficient Capsule Separation: A self-rotating design for the capsule disc ensures that even capsules that fail to separate initially are correctly processed.

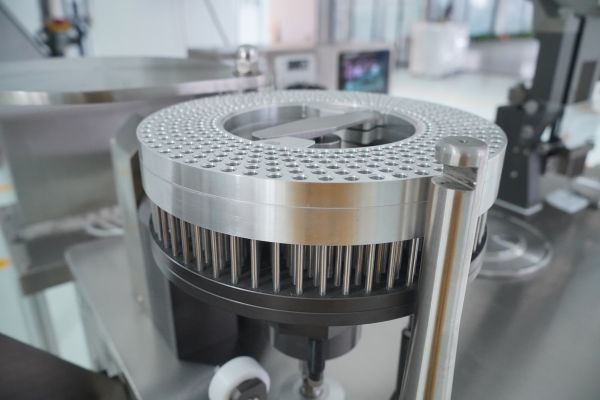

User-Centric and Easy Maintenance:

The CGN208-D1 is engineered for simplicity and minimal maintenance. Patented quick-positioning devices on both the large and small capsule hoppers allow for rapid, tool-free assembly and disassembly. The machine's body and work surfaces are constructed from 304 stainless steel for corrosion and oxidation resistance. Its main technical parameters boast a production capacity of 25,000-30,000 capsules per hour and a quick mold changeover time of 5-10 minutes, making it a highly efficient and versatile machine for handling various capsule sizes (from 00# to 5#) and filling types like powders, pellets, and granules.

3. IMA Group (Italy)

The IMA Group is a global leader in the design and manufacture of automatic machines for the processing and packaging of pharmaceuticals, cosmetics, food, tea, and coffee. Their extensive experience and commitment to innovation are reflected in their high-quality capsule fillers.

Highlights of IMA's Semi-Automatic Offerings:

- Escalabilidad: IMA provides a range of semi-automatic machines that can be a stepping stone to their fully automatic lines, allowing businesses to scale their production as they grow.

- Tecnología avanzada: Their machines often feature cutting-edge technology for precise dosing and weight control, ensuring product quality and compliance.

- Construcción robusta: Built with high-grade materials, IMA's machines are designed for longevity and can withstand the rigors of continuous operation.

4. Marchesini Group (Italy)

Another Italian powerhouse, the Marchesini Group, is renowned for its complete packaging lines for the pharmaceutical and cosmetic industries. Their machines are known for their reliability, efficiency, and innovative design.

Why Choose a Marchesini Machine?

- Integrated Solutions: Marchesini excels at providing integrated solutions, and their semi-automatic capsule fillers are designed to seamlessly connect with other packaging machinery.

- Personalización: They offer a high degree of customization to meet the specific needs of their clients, from product handling to final packaging.

- Soporte postventa: The Marchesini Group is known for its excellent customer service and after-sales support, ensuring that their clients' machines continue to operate at peak performance.

5. MG2 (Italy)

MG2 has been specializing in the design and manufacture of capsule filling machines since 1966. This focus has allowed them to develop a deep understanding of the intricacies of capsule filling technology, resulting in machines that are both innovative and highly reliable.

Distinctive Features of MG2 Fillers:

- Dosing Accuracy: MG2 has developed sophisticated dosing systems that can handle a wide variety of powders with different flow characteristics, ensuring high levels of accuracy.

- Modularity: Their machines often feature a modular design, allowing for easy upgrades and the addition of new functionalities as production needs change.

- Containment Solutions: For handling potent or sensitive products, MG2 offers advanced containment solutions to protect both the operator and the product.

6. Romaco (Germany)

Romaco offers a comprehensive portfolio of processing and packaging technologies for the pharmaceutical industry. Their product lines are known for their engineering excellence and their ability to provide complete, integrated solutions.

Romaco's Strengths:

- Processing Expertise: Romaco's expertise extends beyond filling to include tablet pressing, coating, and granulation, allowing them to offer holistic solutions for solid dosage manufacturing.

- Sustainability: The company places a strong emphasis on developing sustainable technologies that reduce energy consumption and minimize waste.

- Diverse Portfolio: They offer a wide range of machines catering to different production scales, from laboratory and pilot plants to full-scale production.

7. LFA Machines (United Kingdom)

LFA Machines has established itself as a key player in the market by providing a wide range of high-quality and affordable equipment for tablet pressing and capsule filling. They are particularly popular among startups and small to medium-sized businesses.

What Makes LFA Stand Out?

- Accessibility: LFA Machines is dedicated to making high-quality manufacturing equipment accessible to a broader market, offering competitive pricing without compromising on quality.

- Soporte integral: They provide extensive customer support, including training, technical assistance, and a wide range of spare parts and tooling.

- Wide Range of Products: In addition to capsule fillers, they offer tablet presses, mixers, and other related equipment, making them a one-stop shop for many businesses.

8. Fette Compacting (Germany)

While Fette Compacting is primarily known for its world-class tablet presses, they also offer high-performance capsule filling machines that leverage its extensive experience in precision engineering and solid dosage manufacturing.

Fette Compacting's Edge:

- Engineering Excellence: Their machines are a testament to German engineering, known for their robustness, reliability, and long service life.

- High Performance: Fette's equipment is designed for high-speed, continuous operation, making it suitable for demanding production environments.

- Innovation: The company continuously invests in research and development to incorporate the latest technological advancements into its machines.

9. Dott. Bonapace & C. (Italy)

With a history dating back to 1946, Dott. Bonapace & C. has a long and distinguished track record of manufacturing high-quality pharmaceutical machinery. They offer a range of solutions for laboratories and small-scale production.

Key Attributes of Dott. Bonapace Machines:

- Specialization in Small Scale: They are experts in providing solutions for R&D, pilot plants, and small batch production, with machines that are compact and easy to use.

- Quality and Reliability: Despite their smaller scale, their machines are built to the same high-quality standards as larger industrial equipment.

- Flexibilidad: Their equipment is designed to be versatile, allowing for quick changeovers and the handling of a variety of products.

10. MultiGel (Italy)

MultiGel specializes in the production of manual and semi-automatic capsule filling machines for pharmacies, laboratories, and small to medium-sized pharmaceutical and nutraceutical companies.

MultiGel's Niche:

- Focus on Manual and Semi-Automatic: Their specialization in this segment of the market has allowed them to perfect their designs for ease of use, efficiency, and reliability.

- Compact Design: MultiGel's machines are known for their compact footprint, making them ideal for facilities with limited space.

- Made in Italy: All their machines are designed and manufactured in Italy, ensuring high standards of quality and craftsmanship.

Building a Complete Capsule Production Line

A semi-automatic capsule filling machine is a powerful tool, but its efficiency can be further enhanced by integrating it into a complete production line. Here are the key ancillary machines that can be combined to create a seamless workflow:

Máquina pulidora de cápsulas

After the filling process, capsules often have some residual powder on their surface. A capsule polishing machine is used to clean and polish the capsules, giving them a professional and finished appearance. This not only improves the aesthetic quality of the product but also removes any bitter-tasting powder from the capsule surface, enhancing the consumer experience.

Máquina envasadora de blister

Once the capsules are filled and polished, they need to be packaged. A blister packaging machine is used to pack individual capsules into blister packs, which are a common form of packaging for pharmaceuticals and supplements. This provides a secure and tamper-evident packaging solution that also protects the capsules from moisture and contamination.

Maquina estuchadora

The final step in the packaging process is to place the blister packs into cartons. A cartoning machine automates this process, folding the cartons, inserting the blister packs (and often a leaflet), and sealing the cartons. This creates a retail-ready product that is easy to transport and display.

By combining a semi-automatic capsule filling machine with these ancillary machines, businesses can create a highly efficient and automated production line. This not only increases output but also reduces the potential for human error, improves product quality, and ensures consistency from batch to batch.

Conclusión

Choosing the right semi-automatic capsule filling machine is a crucial decision that can significantly impact your production efficiency, product quality, and overall business success. The European market offers a wealth of high-quality options from manufacturers with decades of experience and a commitment to innovation. At the same time, international contenders like Grandpackmachine are challenging the status quo by offering highly competitive and feature-rich machines that provide exceptional value.

When making your selection, it is essential to consider not only the initial purchase price but also the machine's performance, reliability, ease of maintenance, and the availability of after-sales support. By carefully evaluating your needs and exploring the options outlined in this guide, you can find the ideal semi-automatic capsule filling machine to help you achieve your production goals and expand your business.

Referencias

- Revista de Ciencias Farmacéuticas, "A Review of Recent Advances in Capsule Filling Technology."

- Ingeniería farmacéutica, "Optimizing Production Efficiency in Solid Dosage Manufacturing."

- Revista internacional de productos farmacéuticos, "Good Manufacturing Practices for Pharmaceutical Production."