Granulator Farmasi Tempat Tidur Terfluidisasi

Dapatkan efisiensi dan konsistensi yang tak tertandingi dalam pembuatan dosis padat Anda dengan Agung Granulator Fluidized Bed (FBG) yang canggih. Dirancang untuk memenuhi standar industri farmasi, makanan, dan kimia yang ketat, sistem ini secara mulus mengintegrasikan pencampuran, granulasi, dan pengeringan ke dalam satu proses otomatis. Dengan menggabungkan langkah-langkah penting ini, teknologi FBG kami secara drastis mengurangi waktu pemrosesan, meminimalkan penanganan material, dan menurunkan risiko kontaminasi silang, menghasilkan kualitas butiran unggul dalam lingkungan yang mematuhi cGMP.

Hubungi kami

Deskripsi Rinci

Granulator Fluidized Bed kami bukan hanya sekadar peralatan; ini adalah solusi komprehensif untuk menghasilkan butiran yang seragam dan mengalir bebas dengan konsistensi yang luar biasa. Prosesnya dimulai dengan unit penanganan udara canggih kami, yang dilengkapi sistem penyaringan tiga tahap untuk memastikan udara proses bebas dari partikulat, melindungi integritas produk Anda. Dengan fleksibel pilihan pemanas listrik atau uap, Anda dapat mencapai kontrol suhu yang tepat, yang penting untuk hasil yang dapat direproduksi dan melindungi bahan aktif yang sensitif terhadap panas.

Granulasi “satu langkah” atau “pot tunggal” dilakukan dalam sistem tertutup. Bahan dimuat secara efisien melalui mekanisme pemberian makan tertutup dan bertekanan rendah, memastikan keamanan penahanan dan operator. Di dalam wadah produk, partikel dicairkan oleh aliran udara panas yang dikontrol dengan cermat. Nosel presisi tinggi menyemprotkan larutan pengikat ke partikel yang tersuspensi, menyebabkannya menggumpal dan membentuk butiran. Proses ini terus dipantau dan disesuaikan oleh sistem kontrol otomatis, memastikan kondisi optimal dari awal hingga akhir. Setelah granulasi selesai, sistem beralih ke fase pengeringan di ruang yang sama, menghasilkan butiran jadi yang siap untuk tahap produksi berikutnya.

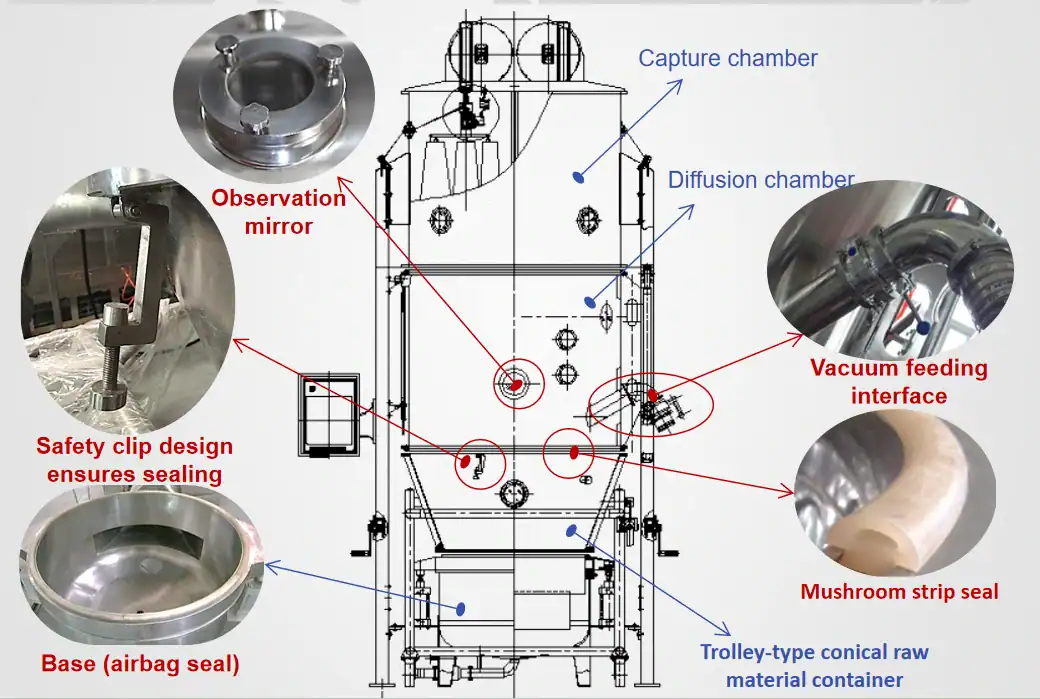

Sistem host tempat tidur terfluidisasi

Fitur

Kontrol Proses Presisi Granulator kami menyediakan kontrol yang tepat atas setiap parameter penting. Katup kontrol pemasukan udara yang intuitif memungkinkan penyetelan halus aliran udara dan kecepatan fluidisasi, sementara sistem pemanas presisi mempertahankan suhu yang stabil. Tingkat kontrol ini menghasilkan distribusi ukuran partikel, kerapatan curah, dan kemampuan alir yang konsisten, dari satu batch ke batch lainnya.

Otomasi Cerdas & Integritas Data (21 CFR Bagian 11 Siap) Inti dari granulator adalah sistem PLC yang kuat yang dipadukan dengan Antarmuka Manusia-Mesin (HMI) yang mudah digunakan. Hal ini menyediakan otomatisasi lengkap dan pemantauan waktu nyata dari keseluruhan proses granulasi. Sistem ini dirancang untuk kepatuhan, memungkinkan Anda menyimpan, mengekspor, dan mencetak parameter proses penting dan data batch dengan mudah, memastikan jejak audit yang jelas untuk persyaratan regulasi.

Pembersihan Otomatis untuk Waktu Aktif Maksimal Minimalkan waktu henti antar batch dengan opsi kami sistem pembersihan otomatis Wash-In-Place (WIP) saluran tunggal atau multi-saluranSiklus yang sepenuhnya otomatis ini memastikan pembersihan yang menyeluruh, dapat diulang, dan dapat divalidasi, sehingga menghemat waktu operator dan membuat Anda siap untuk proses selanjutnya dengan lebih cepat.

Spesifikasi

| Udara Terkompresi: | 0,4-0,7 MPa |

| Kipas Angin: | 18,5 kW |

| Sertifikasi: | CE, ISO |

| Voltase: | Tegangan 380V |

| Spesifikasi: | Ukuran: 3300x2300x2900mm |

| Volume Kontainer: | 22-1500 liter |

| Kapasitas: | 5-500Kg/Batch |

| Peralatan dan Bahan: | baja tahan karat 304,316 |

| Berat: | 1300KG |

Aplikasi

- Farmasi: Sempurna untuk membuat butiran seragam untuk pembuatan tablet dan pengisian kapsul, meningkatkan kompresibilitas dan keseragaman dosis. Digunakan secara luas untuk formulasi pelepasan langsung dan pelepasan terkendali.

- Makanan & Nutraseutika: Ideal untuk memproduksi campuran minuman instan, bubuk sup, bumbu-bumbu, dan suplemen makanan yang membutuhkan sifat kelarutan dan aliran yang sangat baik.

- Kimia: Secara efisien menggranulasi pigmen, deterjen, pupuk, dan senyawa kimia lainnya untuk meningkatkan penanganan, mengurangi debu, dan memastikan kualitas produk yang konsisten.

Detail Mesin

Unit Pengeringan

Nosel