Mesin Beruang Gummy – Lini Produksi Permen Gummy Otomatis Berkecepatan Tinggi

Mesin Granulasi Basah Berkinerja Tinggi | Mixer-Granulator Seri HLSG

Perkenalan

Grand’s HLSG-series high-shear mixer-granulators bring cutting-edge wet granulation to pharmaceutical and nutraceutical production. These powerful granulation machines combine mixing, binder addition, and granule formation in one enclosed cycle. They transform fine powders into dense, uniform granules – a crucial step for creating high-quality tablets and capsules. As one industry source notes, “granulation… transforms fine powder particles into larger, more uniform granules, enhancing flowability, compressibility, and uniformity”. Grand’s design is fully GMP-compliant, clean-in-place (CIP) ready, and easily integrated into automated production lines.

Principle of Wet Granulation in a High-Shear Mixer

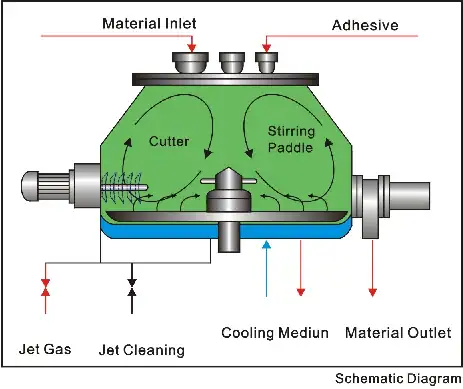

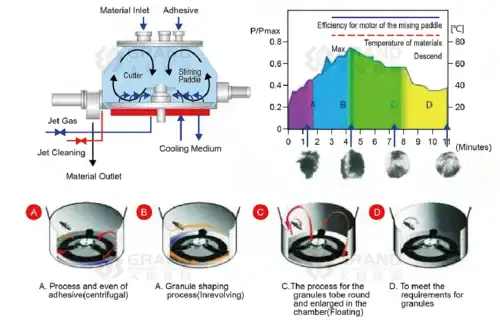

Figure1: Schematic of a high-shear wet granulation process. Powder enters from the top, binder (adhesive) is sprayed in, and the powerful impeller and chopper blades mix and agglomerate the material. A cooling jacket (for temperature control) sits under the bowl, and once granulation is complete the product discharges through a filter outlet.

Di dalam wet granulation process, a liquid binder (often water or a solvent solution) is sprayed onto a bed of powder while high-shear mixing occurs. The binder causes particles to stick and nucleate into small wet agglomerates. Vigorous mixing by a rotating impeller and auxiliary chopper breaks and re-forms agglomerates, growing them into granules. This “binder bridges between particles,” causing primary powder to agglomerate. The impeller speed, mixing time, and binder amount are carefully controlled. Too little binder or speed yields fines; too much yields overgrown granules. Grand’s HLSG mixers allow precise adjustment of mixing (e.g. 20–220 rpm) and granulating speeds (e.g. 50–3000 rpm) for optimal granule size.

These stages are often described as nucleation, growth, and consolidation. Initially, binder wetting creates nuclei or “seed” granules (stage A). Continued shear forms larger but fragile agglomerates (stage B). Choppers then refine and round the granules (stage C), and finally the wet mass densifies into uniform granules with smooth surfaces (stage D). Researchers observe that under optimal conditions, “the most spherical granules with the smoothest surface” are formed when liquid-to-solid and shear rates are balanced. In practice, Grand’s machines produce narrow, consistent granule size distributions through this controlled wetting and shearing.

Compared to dry granulation or other wet methods, high-shear wet granulation offers major advantages: shorter processing time Dan denser, uniform granules. Studies show high-shear granulators achieve faster granulation endpoints and more uniform particle size distributions than many alternatives. This rapid, efficient process meets the rigorous demands of tablet and capsule manufacturing.

“The granulation bowl also contains a chopper to break agglomerates and obtain a uniform granule size distribution” – high-shear mixers are designed for consistent granule uniformity.

Grand HLSG Mixer-Granulator Structure and Operation

Grand’s HLSG-series wet granulators are robust, stainless-steel vessels engineered for hygiene and efficiency. They feature a heavy-duty conical mixing bowl with jacketed sides for heating or cooling, a hinged or lifting lid with a large observation port and spray nozzles, and high-torque drive motors for the impeller and chopper. Internally, an angled impeller blade lifts and collapses the powder for even binder distribution, while a high-speed chopper breaks oversized clumps. The bowl and blades are polished stainless (often 316L grade) to meet GMP cleanliness. A bottom outlet with filter (granulator outlet) collects the wet granules after mixing.

Figure2: Process stages in high-shear wet granulation. (A) Binder is added as fine droplets. (B) Early agglomerates form and break. (C) Granules grow and round off under shear. (D) Final dense granules are formed.

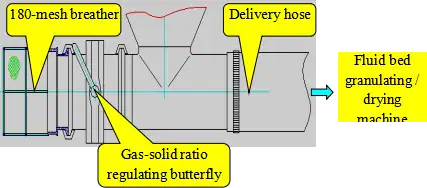

Operation is straightforward: first the dry powders (API and excipients) are loaded, often via an integrated vacuum feeder. Grand offers optional vacuum feeding systems that automatically convey powder into the mixer, eliminating dust and contamination. With powders in place, the impeller and chopper start, and binder is sprayed in. Granulation proceeds under high shear until the endpoint – determined by time, torque, or moisture content – is reached. Then the impeller stops, the pot discharges, and the wet granules exit through the granulator outlet. In many setups, this outlet connects directly (via a breather and hose) to a fluidized bed dryer, as shown in the diagram.

Critically, Grand’s design keeps the process contained and clean. Multiple sealing levels (mechanical and gas seals) and a clamped lid prevent dust release, ensuring isolation and GMP compliance. The internal surfaces and drive components have minimal dead zones – the impeller clearance is under 1.5 mm – so residue is minimized. An optional automatic CIP (clean-in-place) system circulates water or cleaning solution through the vessel and spray nozzles, vastly reducing downtime between batches. In short, the HLSG mixer’s structure enables efficient, hygienic granulation.

Key Performance Features: Speed, Uniformity, and Cleanability

Grand’s HLSG machines are engineered for top performance in demanding production. The high-shear mixing action yields rapid granulation: large batches are processed quickly with shorter cycle times. As one industry report notes, high-shear granulation “can process larger batches of material in shorter timeframes” compared to older methods. This means higher throughput and flexibility in meeting production targets.

At the same time, the intense but controlled shearing produces uniform granules with excellent properties. By breaking and reforming agglomerates under precise conditions, HLSG mixers create a narrow particle size distribution and strong, smooth granules. Tablets made from these granules exhibit consistent hardness and dissolution because the material is homogenous. In practice, downstream processes like tablet presses or capsule filling benefit from improved flow and compressibility of the granules. Grand’s own testing (and user experience) confirm that HLSG-series granulators deliver reproducible particle size and density – a key quality attribute.

Another standout is minimal residue and easy cleaning. The polished 316L bowl, high-clearance agitator design, and CIP nozzles mean less product sticks in corners. After discharging, an automated CIP sequence can spray the vessel walls and agitators clean, allowing swift product changeovers. Grand specifically highlights an integrated CIP system for “streamlining cleaning and changeovers”. This reduces downtime and labor, crucial in GMP environments.

Other features include:

- Vacuum Feeding & Binder Control – Vacuum feeders can continuously supply powder to the mixer, while precise piston or spray pumps deliver binder. This automation reduces manual handling and keeps the process balanced.

- Intelligent Controls – A PLC/HMI control system records process parameters (speed, torque, time) for each batch. Operators can save recipes and generate reports for traceability. Grand units have user-level security and data logging to meet GMP documentation requirements.

- Safety & Isolation – The machine meets FDA/cGMP design: sealed lid, pressure sensors, and optional inerting (N₂ purge) make it safe for flammable solvents. The triple-seal structure prevents contamination between batches.

Together, these innovations mean the HLSG-series granulators give hasil tinggi Dan consistent quality without sacrificing hygiene or regulatory compliance.

Integration: From Mixing to Drying to Packaging

Grand’s wet granulation equipment is part of a full production line. Immediately after the granulator, wet granules typically feed into a fluidized bed granulator/dryer. In a fluid bed, warm air lifts the particles into a “fluid” state, while additional binder can be sprayed (granulation) and then drying occurs all in one vessel. As industry reviews confirm, fluid bed dryers are “the method of choice for wet granules,” offering “rapid heat and mass transfer” and uniform drying. By discharging directly from the HLSG mixer to the fluid bed through a filtered outlet and flexible hose, Grand systems create a seamless hand-off from wet mass to dry granule.

Figure: Connection from granulator outlet to a fluidized bed granulator/dryer. A breather/filter (180-mesh) prevents oversize particles, and a butterfly valve controls airflow. The fluid bed then dries and cools the granules.

In practice, Grand offers various fluid bed units (FG series) that match the HLSG mixers. These are multi-function machines: for example, a fluidized bed granulator uses a spray nozzle and chopper to granulate and dry in one step. Whether in batch or continuous operation, this saves space and improves containment. The combination of high-shear mixer and fluid bed yields high-quality granules ready for final formulation steps. Many customers run lab trials on a small HLSG (e.g. 5–20 L) and corresponding small fluid bed (e.g. FG-15), then scale up to production sizes with identical equipment design – a scalable line approach.

Grand’s product line also includes upstream 3D blenders, volumetric feeders, and high-precision weigh scales for ingredient handling, and downstream tablet presses, capsule fillers, and packaging machines for finished product. On the packaging side, Grand’s own mesin pelabelan Dan cartoners ensure that the final tablets or capsules move seamlessly into final packaging. By offering a complete system of interconnected equipment, Grand enables an end-to-end solution: vacuum conveyors feed powders into the HLSG mixer, granules go to a fluid bed dryer, dried granules can be milled and mixed, then pressed or filled, and finally packaged with labeling and cartoning all from one vendor. This line integration simplifies installation, training, and support.

For example, during transfer the granulator outlet may connect to a flexible hose leading to a granule cooler or fluidized bed dryer. A 180-mesh breather at the outlet ensures only fine particles pass, while large chunks drop back into the granulator for reprocessing. The butterfly valve shown regulates airflow between units. These design details match industrial best practice, avoiding bottlenecks. Grand’s engineering team can also customize interfaces – such as jigs for docking to isolators or transfer ports – to fit existing facilities or containment requirements.

Compliance, Automation, and Traceability

In regulated manufacturing, compliance is non-negotiable. Grand’s machines meet global standards: ISO 9001 and CE certifications, and they are built for FDA/cGMP or EMA inspection. The all-stainless-steel, polish-finished contact parts minimize contamination risk. The equipment has no dead spots and is easy to clean per GMP hygiene guidelines. Grand emphasizes that its granulators are “proven design, GMP ready,” with full material traceability during qualification. All critical operating parameters (batch ID, times, speeds, temperatures) can be logged or printed, satisfying audit trails.

Advanced automation features support these compliance goals. Modern HLSG units use PLC control and touchscreen HMIs. Operators can program multiple recipes (for different products) and the machine will automatically execute each step. If desired, Grand can integrate with plant SCADA or MES systems so the granulator becomes a node in a fully automated line. Digital recording of each batch simplifies validation: a report can show that the correct formula and mixing profile were followed.

User-friendly design aids GMP performance: recipe locking prevents operator error, and alarms/hardware interlocks stop the machine if any parameter goes out of range. The enclosed, ergonomic control panel is often mounted on a swivel arm, and ingredient ports are at comfortable heights. When servicing is needed, many components (seal plates, filters) are designed for quick removal without tools. These design choices reduce human error and maintenance downtime.

In summary, Grand’s HLSG granulators offer state-of-the-art automation and safety. Combined with robust hardware, they ensure efficient, traceable production that passes regulatory muster. Users report that the intuitive HMI and automatic batch logging give confidence and simplify operator training.

Benefits Summary

- Rapid, Efficient Granulation: High-shear action and optimized impeller design cut processing time. As noted by experts, such granulators achieve “shorter processing time” and more reproducible granulation.

- Uniform Granules: Chopper and impeller arrangement yields consistent particle size. Industry reviews highlight how high-shear granulators “result in more uniform particle size and density distribution”, improving tablet quality.

- Minimal Residue & Easy Cleaning: Narrow clearances and CIP nozzles leave little product behind. An integrated CIP system “streamlines cleaning and changeovers”, essential for fast product turns.

- Full Process Control: PLC/HMI controls let you store multiple recipes, monitor mixing torque, and log all data. This ensures consistent batches and audit-ready traceability.

- GMP and Safety: Sealed design, HEPA filtering, and sanitary stainless-steel build mean the HLSG-series meets cGMP, FDA/EMA, and even ATEX requirements for solvent use. Extensive safety interlocks protect operators and product.

These advantages position Grand’s HLSG granulators as top choices for pharmaceutical and nutraceutical manufacturers who need both productivity and quality.

Supporting Equipment and Turnkey Line Integration

Grand’s commitment to a complete solution extends beyond the granulator itself. Upstream, Grand offers vacuum conveyor systems (feeders) to deliver raw powders automatically to the HLSG mixer. These closed systems use an oil-free vacuum pump and filters to convey material without contamination or product loss. By eliminating manual scooping, vacuum feeding improves consistency and operator safety. Grand provides feeders sized for any batch size – from lab-scale to tonnage.

Downstream, Grand’s fluid bed dryers/granulators (FG series) handle drying (and optional secondary granulation) of the wet mass. These tall vessels use heated, pressurized air to fluidize and dry granules uniformly. Grand’s fluid beds are available in lab, pilot, and production scales (FG-15 to FG-500, covering 45–1500 L). All models feature touch-screen controls, spray nozzles, and CIP capability. They can operate as batch dryers or integrated granulators (with bottom or top spray). The benefits are well-documented: fluid bed drying gives “rapid heat and mass transfer” and yields free-flowing granules in one closed step.

Beyond granulation and drying, Grand’s complete packaging automation includes labeling machines, cartoners, blister packers, and more. For example, their rotary and flat labeling systems apply labels with ±1 mm accuracy at high speed. Packaging lines can be configured to take tablets or capsules from the end of the granulation/drying line, through tablet presses or fill-finish, and all the way to boxed product. Importantly, Grand designs connectivity into its control systems so that data flows from one station to the next – from granulator logs through label printing – for full lot traceability.

Altogether, Grand’s HLSG granulator plus supporting equipment form a turnkey manufacturing suite. A pharma plant could equip a production line with a vacuum powder loader, an HLSG-500 mixer, an FG-200 fluid bed, a 3D blender, tablet press, and final packing machines all sourced from Grand. This single-vendor approach simplifies project management and ensures compatibility. Documentation and training also come from one source, easing regulatory qualification.

Kesimpulan

Itu Grand HLSG High-Performance Wet Granulation Machine is a complete solution for quality pharmaceutical granulation. It combines a robust high-shear mixer-granulator with advanced controls, cleaning systems, and full traceability. Granules produced are dense, uniform, and ready for downstream processing. With optional vacuum feeders and built-in CIP, the machine reduces waste, dust, and downtime. Integrated into Grand’s broader equipment suite (fluid bed dryers, tablet presses, packaging), it helps manufacturers build an efficient, GMP-validated production line.

In summary, Grand’s HLSG series offers: ultra-uniform granulation, rapid cycle times, easy cleanability, and seamless automation – all in a package designed to meet cGMP requirements. This makes it ideal for pharmaceutical and nutraceutical producers seeking reliable, high-throughput granulation. With engineering support from Grand and strong academic backing of the wet granulation principle, customers can be confident their processes will be efficient, compliant, and scalable.

Referensi:

1.10 Produsen Mesin Farmasi Teratas

2.Granulator dalam Industri Farmasi – Tinjauan Komprehensif