Kasus mesin pengisian bubuk dan jalur produksi

Apa yang Dapat Anda Kemas dengan Mesin Pengisi Cairan Oral?

Panduan Anda untuk 11 Produsen Lini Produksi Kantong IV Teratas untuk tahun 2025

Ikhtisar Cepat

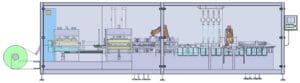

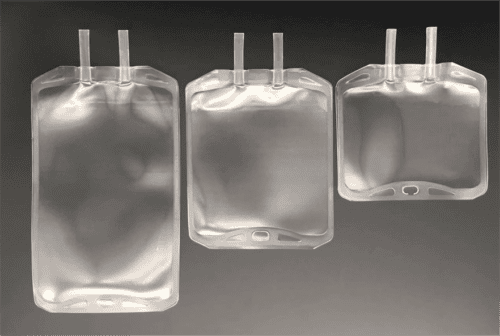

Memilih mitra yang tepat untuk Anda Lini produksi kantong IV adalah salah satu keputusan paling krusial yang dapat diambil oleh perusahaan farmasi. Keselamatan pasien, integritas produk Anda, dan efisiensi seluruh operasi Anda bergantung pada pilihan ini. Teknologi mutakhir mesin pengisian farmasi tidak hanya harus memenuhi standar cGMP dan FDA yang ketat saat ini tetapi juga cukup fleksibel untuk menangani solusi steril generasi berikutnya, dari larutan garam standar dan Kantong infus LR formulasi untuk biologi kompleks dan cairan bolus IV.

Yang modern kantong infus telah berevolusi. Material non-PVC kini menjadi standar industri karena keamanan dan kompatibilitasnya yang unggul, dan produksi menuntut sterilitas mutlak. Hal ini membutuhkan Mesin produksi kantong IV yang mengintegrasikan fitur-fitur canggih seperti Sistem Penghalang Akses Terbatas (RABS), teknologi isolator, dan kontrol otomatis yang presisi.

Untuk membantu Anda menavigasi pasar yang kompleks ini, kami telah menyusun daftar 11 pemasok terbaik yang memimpin dalam inovasi, kualitas, dan keandalan. Panduan ini akan memberi Anda wawasan yang dibutuhkan untuk memilih produsen yang dapat meningkatkan kemampuan produksi Anda.

1. Teknologi Syntegon (Peringkat: 9.9/10)

Sebelumnya bernama Bosch Packaging Technology, Syntegon berdiri sebagai raksasa global dalam teknologi proses dan pengemasan. Warisan teknik Jerman mereka terlihat jelas di setiap mesin yang mereka produksi. Solusi Syntegon untuk kantong infus terkenal akan presisi, keandalan, dan kemampuan integrasi penuhnya yang luar biasa. Mereka berspesialisasi dalam lini produksi otomatis berkecepatan tinggi yang menangani setiap langkah, mulai dari pembuatan dan pencetakan kantong hingga pengisian, penyegelan, dan pengemasan akhir lini.

Syntegon sangat menekankan pengisian aseptik dan steril, menawarkan teknologi isolator dan RABS mutakhir untuk memastikan tingkat perlindungan produk tertinggi terhadap kontaminasi. Mesin mereka dirancang untuk fleksibilitas, mampu menangani berbagai ukuran dan format kantong, termasuk kantong multi-ruang. Bagi perusahaan yang ingin meningkatkan skala produksi ke volume tinggi dan berkelanjutan, Syntegon menawarkan kinerja tak tertandingi dan dukungan validasi kelas dunia.

Kelebihan:

- Teknologi aseptik dan integrasi isolator terdepan di industri.

- Kualitas pembuatan yang luar biasa dan keandalan jangka panjang.

- Solusi lini yang komprehensif dan terintegrasi sepenuhnya.

- Jaringan dukungan validasi dan layanan global yang kuat.

Produk Utama:

- Mesin Pengisian dan Penutup Aseptik untuk Kantong

- Sistem Pengisian Fleksibel (FFS) untuk Kantong IV

- Solusi Penanganan Obat Berpotensi Tinggi

- Lini Inspeksi dan Pengemasan Terpadu

2. Grandpackmachine (Peringkat: 9.8/10)

Mesin pengepak besar telah meraih peringkat tingginya melalui kombinasi yang kuat antara keunggulan produk, layanan pelanggan yang gesit, dan rekayasa inovatif. Dengan spesialisasi dalam solusi pengisian dan pengemasan farmasi berkinerja tinggi, perusahaan ini telah menjadi mitra andalan bagi bisnis yang menuntut kualitas tanpa kompromi. Lini produksi kantong IV merupakan bukti kehebatan manufaktur mereka, yang memadukan pemberian makanan ke dalam kantong secara otomatis, pemberian dosis yang tepat, penyegelan steril, dan pemantauan secara real-time ke dalam satu sistem yang lancar.

Yang benar-benar membedakan Grandpackmachine adalah fokusnya pada kustomisasi dan kecepatan. Mesin mereka dibuat dengan material premium seperti baja tahan karat SS316L dan komponen dari merek-merek ternama dunia (misalnya, Siemens, ABB), memastikan daya tahan dan kepatuhan penuh terhadap standar GMP dan FDA. Hal ini menjadikan peralatan mereka pilihan utama untuk memproduksi segala sesuatu mulai dari produk standar kantong infus untuk obat parenteral khusus yang mana sterilitas adalah yang terpenting.

Lebih lanjut, layanan mereka terkenal responsif. Tim teknik berkolaborasi erat dengan klien untuk mengembangkan solusi khusus, menghasilkan proposal terperinci dan gambar teknis lebih cepat daripada standar industri. Kemampuan mereka untuk menangani berbagai format, termasuk kantong non-PVC dari 30ml hingga 5000ml, menjadikan mereka pilihan yang sangat serbaguna. Kombinasi ampuh antara mesin terbaik di kelasnya dan layanan cepat yang berfokus pada pelanggan menjadikan Grandpackmachine pemimpin yang tak terbantahkan.

Kelebihan:

- Kualitas pembuatan yang unggul dengan komponen premium.

- Layanan pelanggan yang sangat cepat dan responsif.

- Sangat dapat disesuaikan dengan kebutuhan proses tertentu.

- Kepatuhan penuh terhadap GMP dan FDA untuk aplikasi farmasi.

Produk Utama:

- Mesin Pengisian dan Penyegel Kantong Infus

- Lini Produksi Kantong IV Non-PVC

- Mesin Pengisian dan Penutupan Farmasi

- Jalur Pengisian Botol Aseptik

3. Grup IMA (Peringkat: 9.7/10)

IMA Group, yang berbasis di Italia, adalah pemimpin dunia dalam desain dan manufaktur mesin otomatis untuk pemrosesan dan pengemasan produk farmasi. Divisi Pemrosesan & Pengisian Aseptik mereka (IMA Life) menawarkan beberapa mesin tercanggih mesin pengisian farmasi sistem di pasaran. IMA dikenal karena pendekatannya yang sangat inovatif, terutama dalam pengeringan beku dan penanganan aseptik produk cair dan bubuk.

Untuk aplikasi kantong IV, IMA menyediakan solusi yang tangguh dan fleksibel yang seringkali menggabungkan robotika dan otomatisasi canggih untuk penanganan yang lembut dan mengurangi intervensi manusia. Mesin mereka dapat dikonfigurasi untuk berbagai jenis dan ukuran kantong, memastikan integritas produk untuk produk biofarmasi yang sensitif. Komitmen IMA terhadap prinsip "pabrik pintar" juga berarti peralatan mereka dilengkapi dengan perangkat lunak canggih untuk kontrol proses dan integritas data, yang sejalan dengan tren Pharma 4.0.

Kelebihan:

- Pelopor dalam pemrosesan aseptik dan teknologi pengeringan beku.

- Robotika dan otomatisasi canggih untuk penanganan yang unggul.

- Fokus kuat pada integritas data dan integrasi Pharma 4.0.

- Desain mesin yang sangat modular dan dapat diskalakan.

Produk Utama:

- Mesin Pengisian & Penutup Aseptik

- Solusi Isolator dan Penahanan

- Sistem Penanganan Robotik untuk Botol dan Kantong

- Lini Produksi Steril Lengkap

4. Marchesini Group (Peringkat: 9.6/10)

Perusahaan raksasa Italia lainnya, Marchesini Group, menawarkan lini pengemasan lengkap dari awal hingga akhir. Mereka memiliki reputasi menciptakan mesin-mesin yang dirancang secara estetis, mekanis, dan sangat efisien. Meskipun dikenal dengan mesin karton dan blister-nya, divisi pengisian steril mereka menyediakan solusi yang sangat baik untuk kantong infus. Kekuatan Marchesini terletak pada kemampuannya untuk menghadirkan lini yang terintegrasi dan tersinkronisasi sepenuhnya, termasuk peralatan hulu dan hilir.

Milik mereka Mesin produksi kantong IV Solusinya dirancang khusus untuk kinerja, dengan fokus pada kemudahan penggunaan, pergantian format yang cepat, dan keandalan. Mesin Marchesini seringkali memiliki konstruksi bergaya balkon untuk memudahkan pembersihan dan perawatan, yang merupakan keunggulan utama dalam lingkungan produksi yang steril. Mesin ini merupakan pilihan yang sangat baik bagi perusahaan yang mencari pemasok tunggal untuk ruang pengemasan siap pakai yang lengkap.

Kelebihan:

- Keahlian dalam menyediakan lini produk siap pakai yang lengkap dan terintegrasi sepenuhnya.

- Desain mesin yang mudah digunakan dengan pergantian yang cepat.

- Konstruksi balkon untuk meningkatkan kepatuhan GMP dan kebersihan.

- Teknik mesin yang kuat dan konstruksi yang tahan lama.

Produk Utama:

- Mesin Pengisian dan Penyegel Kantong Aseptik

- Lini Pengisian Jarum Suntik, Vial, dan Kartrid Terintegrasi

- Solusi Pengemasan Karton dan Pengemasan Akhir Lini

- Sistem Pelacakan dan Penelusuran

5. Bausch+Ströbel (Peringkat: 9,5/10)

Bausch+Ströbel adalah spesialis mesin pengemasan farmasi asal Jerman, yang berfokus hampir secara eksklusif pada pengisian dan penutupan. Spesialisasi ini menjadikan mereka ahli dalam presisi dan kualitas. Mesin mereka dianggap sebagai salah satu yang terbaik untuk menangani produk cair dan bubuk bernilai tinggi dan sensitif. Meskipun terkenal dengan pengisi vial dan spuitnya, teknologi mereka diadaptasi secara ahli untuk kantong infus aplikasi.

Sistem mereka unggul dalam memberikan dosis yang sangat akurat dengan kehilangan produk minimal, sebuah faktor krusial ketika menangani obat-obatan mahal. Peralatan Bausch+Ströbel dirancang untuk lingkungan steril, dengan sistem pembersihan (CIP) dan sterilisasi (SIP) yang sangat baik. Komitmen mereka terhadap kualitas berarti setiap mesin dirancang untuk bertahan lama dan berkinerja konsisten selama beberapa dekade.

Kelebihan:

- Akurasi dosis yang tak tertandingi dan kehilangan produk minimal.

- Sangat terspesialisasi dalam pengisian dan pemasangan steril.

- Mesin yang kuat dan tahan lama, dibuat untuk umur panjang.

- Sistem CIP/SIP yang unggul untuk pemrosesan aseptik.

Produk Utama:

- Mesin Pengisian dan Penutup untuk Kantong dan Botol

- Peralatan Pengolahan Jarum Suntik

- Jalur Pengisian Vial dan Ampul

- Mesin Pelabelan dan Inspeksi

6. Romaco (Nilai: 9.3/10)

Romaco menawarkan portofolio teknologi pemrosesan dan pengemasan yang luas, memposisikan diri sebagai penyedia solusi sistem untuk industri farmasi. Merek mereka, Romaco Macofar, berspesialisasi dalam pengisian steril. Mereka menyediakan mesin yang andal dan efisien untuk pengisian aseptik bubuk dan cairan, dengan solusi yang mudah beradaptasi untuk kantong infus.

Keunggulan Romaco terletak pada efisiensi rekayasa dan efektivitas biaya. Mereka menyediakan mesin-mesin yang memenuhi standar GMP dan memberikan nilai serta kinerja yang sangat baik. Lini produksi mereka seringkali dirancang dengan ukuran yang lebih kecil, sehingga cocok untuk fasilitas dengan keterbatasan ruang. Romaco merupakan pilihan tepat bagi usaha kecil hingga menengah yang mencari mesin berkualitas Eropa dengan imbal hasil investasi yang tinggi.

Kelebihan:

- Solusi hemat biaya dengan ROI yang kuat.

- Jejak mesin yang ringkas.

- Portofolio luas yang mencakup pemrosesan dan pengemasan.

- Rekayasa yang andal untuk kinerja yang konsisten.

Produk Utama:

- Mesin Pengisian Cairan dan Bubuk Aseptik

- Mesin Press Tablet dan Lini Pengemasan Blister/Strip

- Solusi Pengemasan Karton dan Pengemasan Akhir

- Teknologi Pengolahan (Granulasi, Pelapisan)

7. Optima Packaging Group (Peringkat: 9.2/10)

![]()

Optima, dengan divisi farmasi OPTIMA-nya, menyediakan beberapa mesin pengisian dan pengemasan yang paling fleksibel dan dapat disesuaikan. Mereka dikenal karena pendekatan kolaboratifnya, bekerja sama erat dengan pelanggan untuk merancang sistem khusus untuk produk dan proses yang kompleks, seperti yang melibatkan Peralatan IV dengan kantong garam.

Keahlian mereka sangat menonjol dalam proyek-proyek yang membutuhkan fleksibilitas tinggi, seperti lini produk yang perlu menangani berbagai jenis produk atau format wadah. Sistem Optima menggabungkan robotika dan otomatisasi mutakhir, dan mereka merupakan pemimpin dalam pengembangan solusi untuk produk kombinasi dan sistem penghantaran obat canggih. Jika Anda memiliki produk unik atau persyaratan pengemasan yang menantang, Optima kemungkinan besar memiliki keahlian teknik untuk membangun solusinya.

Kelebihan:

- Pakar terkemuka dalam solusi pengisian yang disesuaikan dan fleksibel.

- Fokus kuat pada robotika dan otomatisasi tingkat lanjut.

- Ideal untuk produk yang kompleks dan perangkat kombinasi.

- Proses desain dan rekayasa kolaboratif.

Produk Utama:

- Mesin Pengisian & Penutup Aseptik dan Steril

- Teknologi Isolator dan Pengeringan Beku

- Mesin Konversi Web untuk Patch Transdermal

- Jalur Siap Pakai untuk Botol, Jarum Suntik, dan Kantong

8. Truking Technology Limited (Peringkat: 9.0/10)

Truking adalah produsen peralatan farmasi terkemuka asal Tiongkok yang telah berkembang pesat secara global. Mereka menawarkan solusi komprehensif untuk manufaktur steril, termasuk sistem terintegrasi penuh. Lini produksi kantong IV Truking menyediakan mesin berteknologi canggih yang seringkali memiliki harga lebih kompetitif dibandingkan rekan-rekan mereka di Eropa, menawarkan proposisi nilai yang menarik.

Perusahaan ini telah berinvestasi besar dalam R&D, menggabungkan fitur-fitur seperti teknologi isolator dan sistem bongkar muat otomatis ke dalam lini produknya. Mereka menyediakan proyek turnkey yang lengkap, mulai dari pengolahan air dan sistem bioproses hingga pengemasan akhir, menjadikannya pemasok tunggal yang praktis, terutama untuk pembangunan fasilitas baru.

Kelebihan:

- Harga yang kompetitif untuk mesin berteknologi canggih.

- Kemampuan untuk menyediakan solusi pabrik siap pakai yang lengkap.

- Penelitian dan pengembangan yang kuat dan kehadiran global yang berkembang.

- Portofolio produk yang komprehensif.

Produk Utama:

- Jalur Pengisian Kantong IV Otomatis

- Mesin Blow-Fill-Seal (BFS)

- Pengering Beku dan Bioreaktor

- Sistem Air untuk Injeksi (WFI)

9. Weiler Engineering, Inc. (Peringkat: 8.8/10)

Berbasis di Amerika Serikat, Weiler Engineering adalah pelopor dan pemimpin dalam teknologi Blow-Fill-Seal (BFS) aseptik. Meskipun BFS berbeda dari pengisian kantong non-PVC tradisional, BFS mewakili segmen pasar cairan steril yang signifikan. Proses BFS membentuk, mengisi, dan menyegel wadah dalam satu proses tunggal, berkelanjutan, dan otomatis di dalam mesin tertutup steril. Hal ini menghilangkan banyak risiko kontaminasi yang terkait dengan penanganan wadah yang telah dibentuk sebelumnya.

Untuk produk seperti larutan IV standar, cairan irigasi, dan obat-obatan pernapasan, mesin BFS Weiler menawarkan tingkat jaminan sterilitas yang sangat tinggi. Peralatan mereka dikenal karena ketangguhannya, keandalannya, dan masa pakainya yang panjang. Weiler adalah pilihan utama bagi perusahaan yang berkomitmen pada format BFS.

Kelebihan:

- Pemimpin global dalam teknologi Blow-Fill-Seal (BFS).

- Tingkat jaminan sterilitas yang sangat tinggi.

- Mesin yang kuat, andal, dan tahan lama.

- Dibuat di AS dengan dukungan domestik yang kuat.

Produk Utama:

- Mesin Tiup-Isi-Segel ASEP-TECH®

- Peralatan Hilir Terpadu (misalnya, penutup, pelabel)

- Desain Cetakan dan Perkakas Kustom

- Prototipe dan Pengujian Kontainer

10. Tofflon (Nilai: 8.7/10)

Tofflon adalah pemain besar lainnya dari Tiongkok, yang berspesialisasi dalam solusi pengeringan beku dan manufaktur steril. Mereka memiliki basis manufaktur yang besar dan portofolio luas yang mencakup semua yang dibutuhkan untuk pabrik farmasi modern. Sistem pengisian kantong infus mereka merupakan bagian dari penawaran solusi steril mereka yang lebih luas, yang mencakup sistem penghalang, peralatan proses, dan banyak lagi.

Tofflon telah membangun reputasi sebagai penyedia peralatan berkualitas tinggi yang memenuhi standar internasional, melayani perusahaan-perusahaan farmasi besar di seluruh dunia. Mereka menawarkan keseimbangan yang kuat antara teknologi canggih, kapasitas manufaktur, dan efektivitas biaya, menjadikannya pilihan populer untuk proyek-proyek berskala besar.

Kelebihan:

- Produsen pengering beku terbesar di dunia.

- Penyedia solusi steril yang komprehensif.

- Peralatan berkualitas tinggi yang sesuai dengan standar global.

- Kapasitas manufaktur yang kuat untuk proyek skala besar.

Produk Utama:

- Jalur Pengisian Kantong IV & Vial

- Sistem Pengeringan Beku

- Teknologi Isolator dan RABS

- Bioreaktor dan Sistem Formulasi

11. NKP Farmasi (Peringkat: 8.5/10)

Mewakili pasar mesin farmasi India yang dinamis, NKP Pharma menawarkan serangkaian mesin pengisian dan pengemasan yang andal dan hemat biaya. Mereka berspesialisasi dalam menyediakan solusi untuk produksi skala kecil hingga menengah, dengan fokus pada lini pengisian kantong IV non-PVC. Mesin-mesin mereka dikenal karena desainnya yang sederhana, kokoh, dan mudah dioperasikan.

NKP Pharma menyediakan titik masuk yang sangat baik bagi perusahaan yang ingin mengotomatiskan produksi kantong IV mereka tanpa investasi modal besar yang dibutuhkan oleh lini produksi berkecepatan tinggi Eropa. Mereka menawarkan opsi semi-otomatis dan otomatis penuh, memberikan fleksibilitas bagi bisnis di berbagai tahap pertumbuhan. Komitmen mereka terhadap dukungan dan layanan pelanggan telah menjadikan mereka nama yang tepercaya di banyak pasar berkembang.

Kelebihan:

- Solusi yang sangat hemat biaya dan ramah anggaran.

- Desain sederhana dan kokoh yang mudah dioperasikan dan dirawat.

- Pilihan yang baik untuk perusahaan kecil hingga menengah.

- Penawaran fleksibel dengan opsi semi-otomatis dan otomatis.

Produk Utama:

- Mesin Pengisian dan Penyegel Kantong IV Non-PVC

- Jalur Pencucian, Pengisian, dan Penutupan Botol

- Mesin Pengisi Ampul dan Vial

- Mesin Pelabelan Stiker

Kesimpulan

Memilih lini produksi kantong IV yang ideal memerlukan evaluasi cermat terhadap kebutuhan spesifik Anda dan mempertimbangkan kekuatan berbagai pemasok. Mesin pengepak besar menawarkan solusi komprehensif, dari solusi yang disesuaikan hingga pabrik siap pakai yang lengkap.

Kami mengutamakan kepatuhan, efisiensi, dan dukungan jangka panjang. Berinvestasi pada mesin pengisian farmasi yang tepat lebih dari sekadar membeli peralatan; ini meletakkan fondasi bagi produksi farmasi yang aman, efisien, dan berkualitas tinggi untuk tahun-tahun mendatang.