グランドふるい機シリーズの紹介

主な機能と利点

当社の機械は、比類のないパフォーマンスと信頼性を実現するために高度なテクノロジーを使用して構築されています。

✅拡張除塵パス: 当社の機械は長い螺旋経路(最大 7.5 メートル)を備えており、錠剤をすべての面から丁寧にタンブリングして研磨し、優れた仕上がりを実現します。

✅高効率ふるい分け: 革新的な設計により、錠剤に損傷、欠け、ひび割れを生じさせることなく、効果的な除塵と研磨を保証します。

✅調整可能な速度制御: タブレット プレスの出力に合わせて除塵機の速度を簡単に調整できるため、スムーズで継続的なワークフローを実現できます。

✅360°調整可能: 入口ポートと出口ポートは 360° 回転できるため、あらゆる生産レイアウトに適合する最大限の柔軟性が得られます。

✅cGMP準拠: 死角がなく、簡単に分解・洗浄できる設計です。すべての接触部品は高品質の耐腐食性材料で作られています。

主な用途

グランドふるい機は、精密な錠剤仕上げを必要とする幅広い業界にとって重要な装置です。

医薬品: 標準的なコーティングされていない錠剤から発泡性錠剤やチュアブル錠剤まで、あらゆるタイプの錠剤の除塵と研磨に使用します。

栄養補助食品: 清潔でプロフェッショナルな外観が重要なビタミン、ミネラル、ハーブサプリメントに最適です。

食品・菓子: きれいで光沢のあるキャンディタブレット、ミント、その他の圧縮食品の製造に最適です。

化学工学: 特殊触媒、洗剤、その他の圧縮粉末の除塵に適しています。

錠剤ふるい分け機の主な特徴

当社のマシンには、次のような数多くの高度な機能が組み込まれています。

- 360度調整可能な入口と出口 充填機やその他の生産設備と簡単に調整できます。

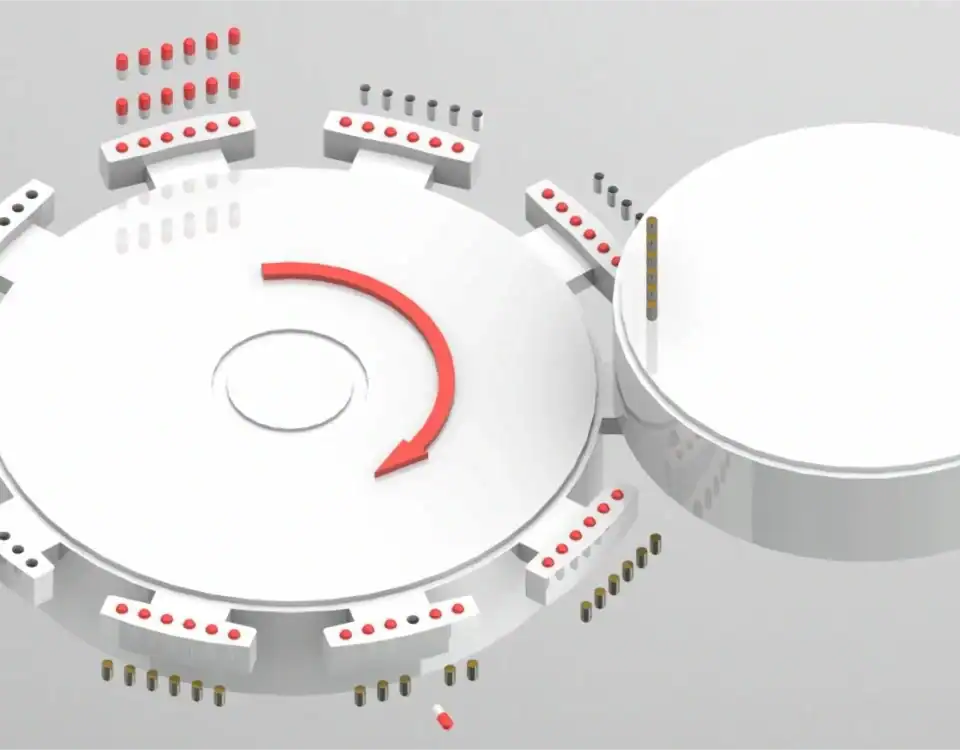

- 自動仕分け機構 内容物の入ったカプセル、空の殻、破片、割れた本体を区別します。

- クイックフィルデザイン 簡単に分解して清掃できるため、メンテナンス時のダウンタイムを最小限に抑えることができます。

- ステンレス鋼(316L)接触部品 現代の医薬品製造基準を満たし、耐久性と安全性を確保しています。

- GMP準拠の洗浄システム 行き止まりがなく、衛生管理も徹底しています。

- 集塵システム クリーンな生産環境を維持するため。

パラメータ比較

| パラメータ | グランドSZS230 | グランドSZS750 |

|---|---|---|

| モデル | SZS230 | SZS750 |

| 最大出力(錠剤/時) | 約1,000,000(Ø4mmの場合) | 約3,000,000(Ø5mmの場合) |

| 除塵距離 | 6.2メートル | 7.5メートル |

| 最大錠剤直径 | Φ20mm | Φ25mm |

| 電源 | 110V/220V、50/60Hz | 110V/220V、50/60Hz |

| 力 | 150ワット | 300ワット |

| 騒音レベル | 75 dB未満 | 75 dB未満 |

| 寸法(mm) | 500×550×(1350-1500) | 480x480x(1445-1640) |

| 重さ | 75キロ | 80キロ |

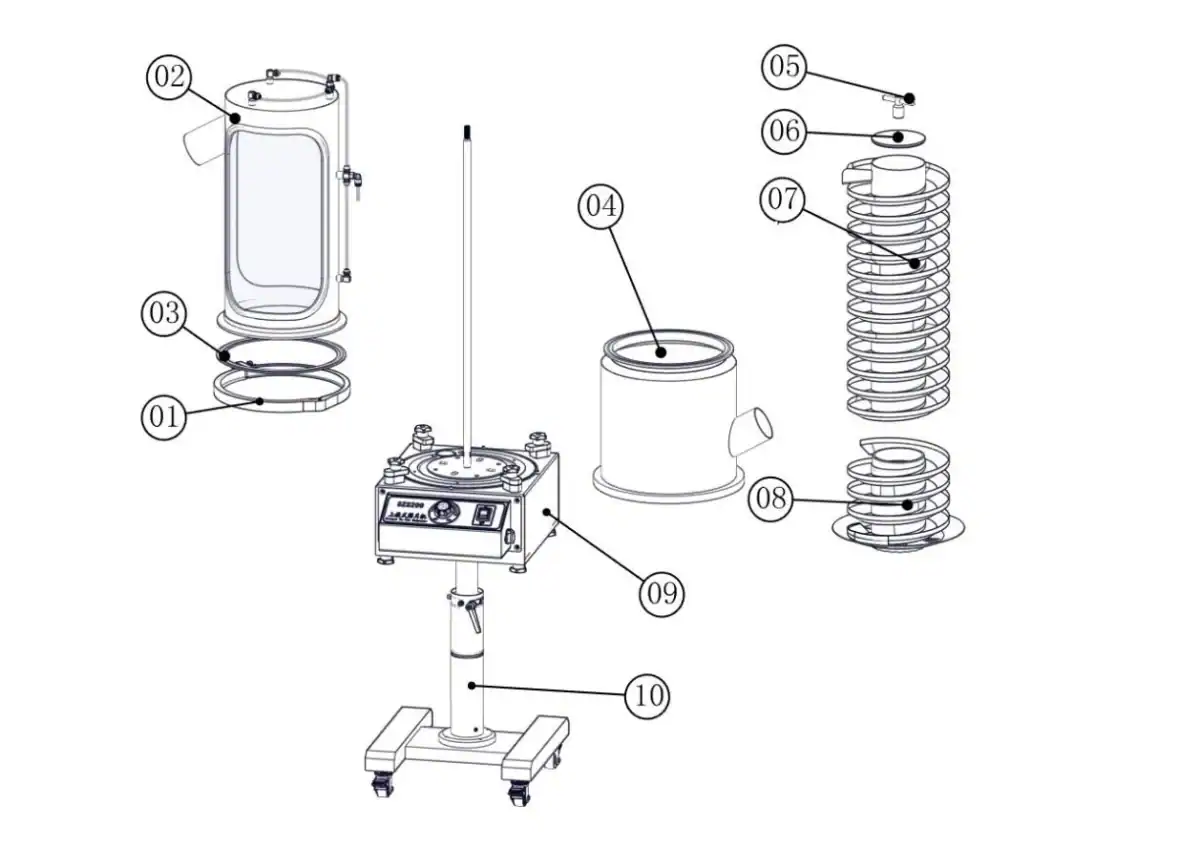

01 クランプ

02 体の2番目の部分

03 シールリング

04 体の第1部分

05クロスハンドル

06プレスプレート

07 ふるい網の2番目の部分

08 ふるい網の1番目の部分

09 電気ボックス、ドライブと

電源制御

10 上下列

高度な構造と設計

グランドのすべてのコンポーネント ふるい機 安全性、安定性、使いやすさを考慮して設計されています。

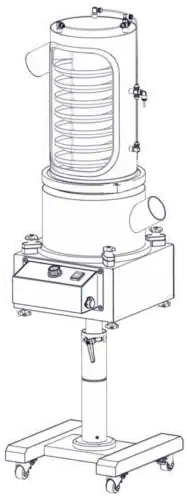

モバイルオペレーティングプラットフォーム: ロック可能なキャスターを備えた堅牢なシャーシは、操作中の最大限の安定性と、必要に応じて容易に移動できることを保証します。高さ調節可能なフレームにより、他の機械との完璧な位置合わせが可能です。

主な作業組織: 機械の心臓部は振動体で、螺旋状の除塵経路を駆動します。一体型の集塵プレートと真空ポートは外部の真空システムに接続され、除去された粉塵を効率的に除去します。

密封された外側のカバー: 観察窓を備えた完全密閉チャンバーは、交差汚染を防ぎ、プロセス全体を安全に監視できます。工具を使わずに分解できる構造のため、清掃が迅速かつ容易です。

タブレットの生産を向上させる準備はできていますか? 今すぐ見積もりをご希望の場合はお問い合わせください。

機械の詳細に注目

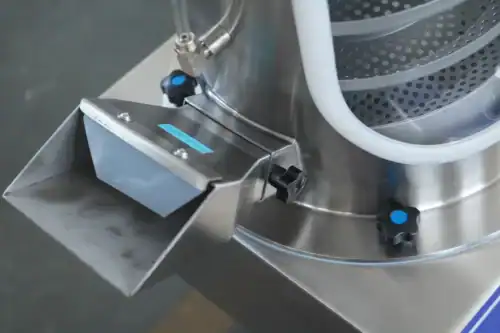

スクリーンマシン出口

ふるい機のコントロールノブ

スクリーンの内部ディスク

スクリーンマシンのフィードポート