規制対象機械の輸入にDEAライセンスを取得するにはどうすればいいですか?

ブリスター包装:化粧品業界に最適

錠剤カウンター機 – 医薬品業界最高精度

導入

製薬業界では、精度は重要であるだけでなく、不可欠です。患者の健康は、適切な薬を適切な用量で投与することにかかっています。この精度を確保するのは、多くの場合、 錠剤カウンターこれらの自動化システムは、 錠剤とカプセルの計数機 ユニットは、錠剤、タブレット、カプセルを正確に計数します。これらは現代の医薬品包装において重要な役割を担い、大量生産から患者様への最終製品供給までを繋ぎます。

これらの機械は、人間よりもはるかに正確に計数することで患者の安全性を高め、投薬ミスを減らすため、非常に重要な存在です。また、高速自動化によって効率性も向上し、人件費を削減し、生産をスピードアップさせます。この記事では、正確な計数がなぜ重要なのかを探り、その基本的な要素を解説します。 錠剤カウンター機械部品、次のような高品質の機械の特徴を調べます グランドGDS-8、適切な機器を選択するためのヒントも提供します。

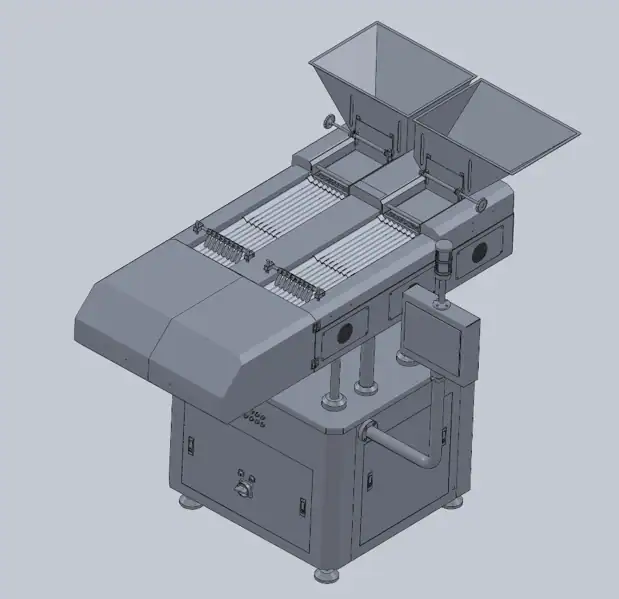

グランドタブレット・カプセル計数機 GDS-8

正確な錠剤カウントが重要な理由

正確な錠剤カウントは、患者の安全、規制遵守、製薬業界および栄養補助食品業界の業務効率にとって不可欠です。

患者の安全第一

正確な計数の主な目的は、患者の健康被害を防ぐことです。計数ミスは、過少投与(治療効果の低下)や過剰投与(副作用やより深刻な事態を引き起こす)につながる可能性があります。残念ながら、投薬ミスは頻繁に発生し、大きな損失を招いており、米国だけでも毎年数百万人に影響を与え、数千人の死者を出しています。手作業による計数は、特に投薬量や薬剤の誤りといった人為的ミスが発生しやすいものです。 自動錠剤カウンター 自動化によりこれらのリスクが大幅に軽減され、安全性が大幅に向上します。研究によると、自動化によって調剤ミスを大幅に削減できることが示されています。

運用効率の向上

安全を超えて、 自動錠剤カウンター テクノロジーは効率性を高めます。手作業での計数は時間がかかり、労働集約的です。自動化システムは毎分数千錠の錠剤を計数し、スループットを大幅に向上させます。この高速化により人件費が削減され、スタッフはより複雑な作業に専念できます。これらの機械は生産ラインにスムーズに統合され、ボトルネックを解消し、ターンアラウンドを迅速化します。正確な計数は、製品の廃棄を最小限に抑えます。

規制遵守と品質

FDAなどの厳格な規制では、医薬品のラベル表示と調剤の正確性が求められています。遵守違反は深刻な結果につながる可能性があります。現代の 錠剤カウンター ユニットは、コンプライアンスに不可欠な追跡・記録システムと統合されることがよくあります。自動化システムは、一貫した計数を可能にし、適正製造基準(GMP)に準拠し、リコールリスクを軽減します。検証済みの正確な計数技術を使用することで、堅牢な品質管理を実証できます。

自動薬剤カウンターの構造

ほとんど 自動錠剤カウンター 各ユニットは、正確なカウントのために連携して機能するコアコンポーネントを共有しています。これらを理解することで 錠剤カウンター機械部品 鍵となるのは:

- ホッパー: 大量の錠剤/カプセルを保管し、振動を利用して機械に送り込みます。

- 調整可能なフィードゲート: 過負荷を防ぐためにホッパーからの錠剤の流れを制御します。

- 振動プレート: 振動を利用して錠剤を分離し、チャネルに整列させて正確に計数します。

- センサーヘッドのカウント: 通過する各錠剤を検出します。通常は光電センサー (「フォトアイ」) または高度なビジョン システムを使用します。防塵センサーにより信頼性が向上します。

- 充填漏斗: ガイドは数えられた錠剤を容器に投入し、こぼれを最小限に抑えます。

- ボトルコンベア: コンテナを充填位置に移動し、自動化されたラインで下流に輸送します。

- 光電センサー(ボトル検出) コンベア上のボトルの存在と位置を検出し、ボトルのこぼれや容器なしでのカウントを防止します。

- ボトルリジェクトシステム: 数量が不正確なボトルやその他の欠陥が検出されたボトルを自動的に削除し、品質を保証します。

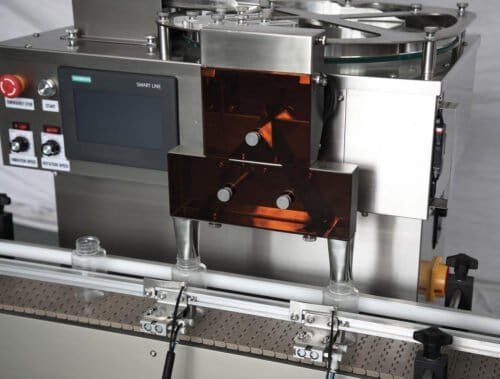

- HMIタッチスクリーン: オペレーターは、ユーザーフレンドリーなインターフェースを使用してパラメータを設定し、状態を監視し、マシンを管理できます。

- 電気筐体: 電気部品を保護し、オペレーターの安全を確保します。

- 集塵マニホールド: 集塵システムに接続して空気中の粒子を除去し、清潔さとセンサーの精度を維持します。

- ダストカバー: 処理エリアを囲むことで粉塵を封じ込め、排出効率を向上させます。

高品質の薬剤カウンターの特徴

トップクラス 錠剤カウンター これらのモデルは、精度、効率、信頼性を高める機能を備えています。

- 高度なセンサー: 高速またはビジョンベースのセンサー、特に防塵光電センサーは、困難な製品でも高い精度(多くの場合、>99.8%)を保証します。

- 効率的な設計: 精密な振動制御により製品の損傷を防ぎます。マルチチャネル設計により速度が向上します。 ツール不要の切り替えにより、ダウンタイムが短縮され、清掃が簡単になります。堅牢な GMP 準拠の素材により耐久性が保証されます。

- 使いやすさ: 直感的な HMI タッチスクリーンにより、操作と監視が簡単になります。6 メンテナンスが容易なので、所有コストが削減されます。

ケーススタディ:Grand GDS-8 錠剤・カプセル計数機

グランドGDS-8 錠剤とカプセルの計数機 これらの品質特性を例示します。 各種錠剤、カプセル(ハード、ソフト)、丸剤に適した自動電子カウンターです。

効率を高める主な要因としては、マルチチャネル設計(おそらく 8 チャネル)、タッチスクリーン HMI による PLC 制御、自動化ラインの統合機能などがあります。 特許取得済みの振動システムによりスムーズな排出が可能になり、工具なしで分解できるためメンテナンスが簡単です。

品質に関しては、GDS-8 は独自の「高塵埃対策」センサーを使用しており、埃っぽい状況でも精度を保ち、潜在的に 99.8% を超えるレートを実現します。 これには、「ボトルがない場合はカウントしません」などのチェックや自動拒否システムが含まれます。多様な製品を優しく扱う設計です。Grand Machinery は信頼できる品質と安定したパフォーマンスを重視しています。 GDS-8 は、精度、効率、信頼性、GMP 準拠に対する業界のニーズに直接対応します。

適切な薬剤カウンターの選択

最良のものを選ぶ 錠剤カウンター お客様のニーズとマシンの機能を一致させることが含まれます。

- 音量: 必要な速度 (ボトル/分) によって、半自動か全自動か、およびチャネル数が決まります。

- 製品: サイズ、形状、壊れやすさ、ほこりっぽさは、センサーと処理システムの選択に影響します。

- 正確さ: 適切なセンサー技術を選択するために、許容できる誤差を定義します。

- 統合: 既存の生産ライン設備との互換性を確保します。

- 予算: 初期コストと効率および品質による長期的な節約のバランスを取ります。

- コンプライアンス: GMP 標準と検証サポート (IQ/OQ/PQ) を検証します。

- 使いやすさ: 操作の容易さ、清掃、切り替え、ベンダーのサポートを考慮してください。

結論

錠剤カウンター 医薬品の安全性と効率性には、テクノロジーが不可欠です。これらの機械は正確な投薬量を確保し、投薬ミスを減らします。自動化により生産性も向上します。コアの機能を理解する 錠剤カウンター機械部品ホッパーからセンサー、リジェクトシステムに至るまで、あらゆる要素が、そのメリットを最大限に活用するための鍵となります。質の高い 自動錠剤カウンター 製品の完全性、患者の安全、および運用の成功を確保するための戦略的な動きです。

また、 医薬品充填生産ライン。 続きを読む:

1.錠剤計数機:概要、動作原理、種類、主なコンポーネント、購入のヒント