그랜드 제약용 체질기: 최고의 정제 제진 및 연마 솔루션

현대 제약 및 건강기능식품 생산에서 정제 품질과 공정 효율성은 양보할 수 없는 요소입니다. 멋진 체질기 시리즈는 최고의 성능을 위해 설계되었습니다. 태블릿 프레스 보조 기계, 승강, 먼지 제거, 연마를 하나의 신뢰할 수 있는 장치로 결합합니다. 상향 회전 체질기 기존 장비와 완벽하게 통합됩니다. 전자동 태블릿 프레스 그리고 금속 탐지기를 사용하여 효율적이고 간소화된 cGMP 규격 생산 라인을 구축했습니다.

그랜드 시빙 머신 시리즈 소개

주요 기능 및 장점

당사의 기계는 첨단 기술로 제작되어 탁월한 성능과 안정성을 제공합니다.

✅확장된 먼지 제거 경로: 최대 7.5m의 긴 나선형 경로를 갖춘 이 기계는 태블릿을 모든 면에서 부드럽게 굴리고 광택을 내어 최상의 마감을 보장합니다.

✅고효율 체질: 혁신적인 디자인으로 태블릿에 손상, 깨짐, 균열을 일으키지 않고 효과적인 먼지 제거 및 광택 작업을 보장합니다.

✅조절 가능한 속도 제어: 원활하고 지속적인 작업 흐름을 위해 태블릿 프레스의 출력에 맞춰 먼지 제거기의 속도를 쉽게 조절할 수 있습니다.

✅360° 조절 가능: 입구 및 출구 포트는 360° 회전이 가능하여 모든 생산 레이아웃에 맞춰 최대한의 유연성을 제공합니다.

✅cGMP 준수: 사각지대 없이 간편하게 분해 및 세척할 수 있도록 설계되었습니다. 모든 접촉부는 고품질의 내식성 소재로 제작되었습니다.

주요 응용 분야

그랜드 시빙 머신은 정밀한 태블릿 마감이 필요한 광범위한 산업에 필수적인 장비입니다.

제약품: 표준 무코팅 정제부터 발포성 정제, 씹는 정제까지 모든 유형의 정제의 먼지 제거 및 광택 처리에 적합합니다.

건강기능식품: 깨끗하고 전문적인 모습이 중요한 비타민, 미네랄, 허브 보충제에 적합합니다.

식품 및 과자류: 깨끗하고 윤이 나는 사탕 정제, 민트, 기타 압축 식품을 생산하는 데 이상적입니다.

화학공학: 특수 촉매, 세제 및 기타 압축 분말의 먼지 제거에 적합합니다.

알약 체질기의 주요 특징

당사의 기계는 다음을 포함한 다양한 고급 기능을 통합했습니다.

- 360도 조절 가능한 입구 및 출구 충전기 및 기타 생산 장비와 쉽게 정렬할 수 있습니다.

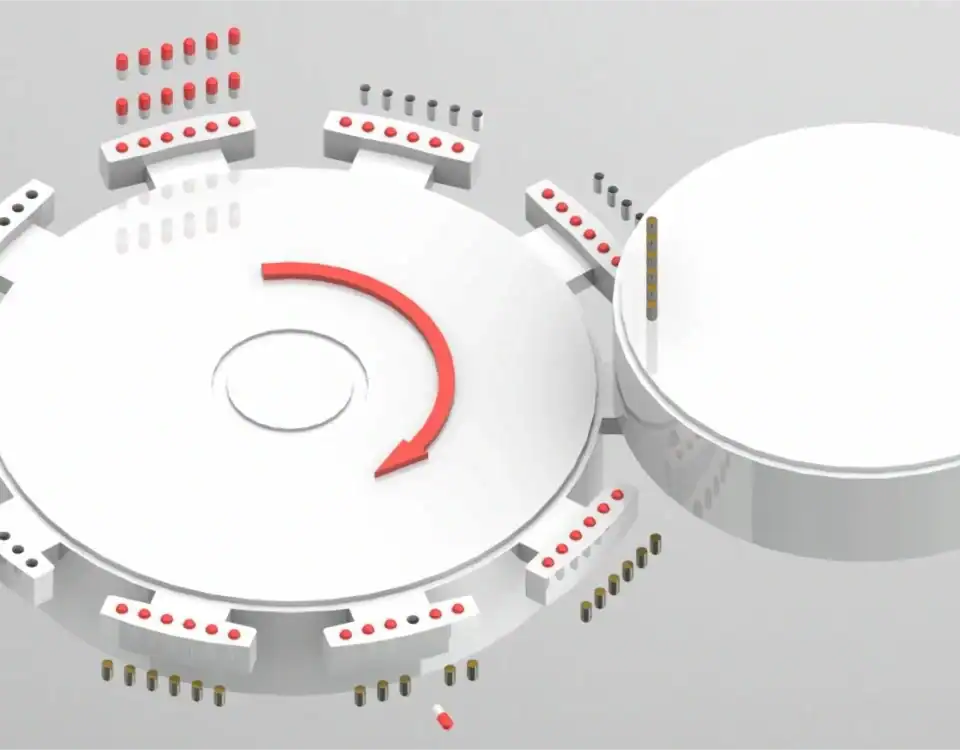

- 자동 분류 메커니즘 내용물이 있는 캡슐, 빈 껍질, 파편, 분리된 몸체를 구별합니다.

- 빠른 채우기 디자인 쉽게 분해하고 청소할 수 있어 유지관리 시 가동 중지 시간을 최소화할 수 있습니다.

- 스테인레스 스틸(316L) 접촉부 현대의 제약 제조 기준을 충족하여 내구성과 안전성을 보장합니다.

- GMP 규격에 맞는 세척 시스템 막다른 길이 없어 철저한 위생 관리를 지원합니다.

- 집진 시스템 깨끗한 생산 환경을 유지합니다.

매개변수 비교

| 매개변수 | 그랜드 SZS230 | 그랜드 SZS750 |

|---|---|---|

| 모델 | SZS230 | SZS750 |

| 최대 출력(정제/시간) | ~1,000,000 (Ø4mm 기준) | ~3,000,000 (Ø5mm 기준) |

| 먼지 제거 거리 | 6.2m | 7.5m |

| 최대 정제 직경 | Φ20mm | Φ25mm |

| 전원 공급 장치 | 110V/220V, 50/60Hz | 110V/220V, 50/60Hz |

| 힘 | 150와트 | 300와트 |

| 소음 수준 | <75dB | <75dB |

| 치수(mm) | 500×550×(1350-1500) | 480x480x(1445-1640) |

| 무게 | 75kg | 80kg |

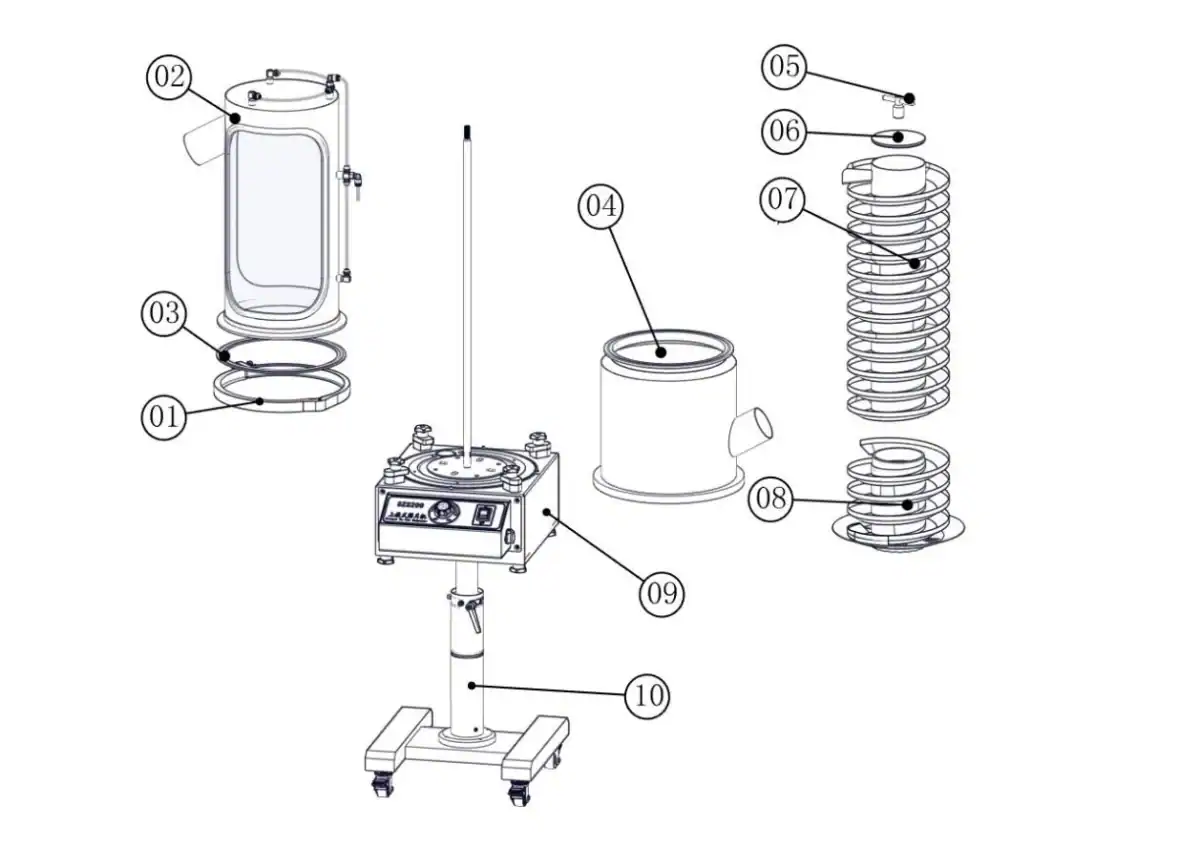

01 클램프

02 신체의 두 번째 부분

03 씰링

04 신체의 첫 번째 부분

05 크로스 핸들

06 프레스 플레이트

07 체망 2번째 부분

08 체망 1번째 부분

09 전기 박스, 드라이브 및

전원 공급 장치 제어

10 위아래 열

고급 구조 및 설계

그랜드의 모든 구성 요소 체질기 안전성, 안정성, 사용 편의성을 고려하여 설계되었습니다.

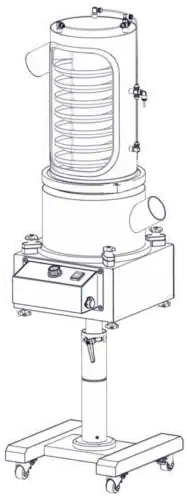

모바일 운영 플랫폼: 잠금식 캐스터가 장착된 견고한 섀시는 작동 중 최고의 안정성을 보장하고 필요 시 편리한 이동을 보장합니다. 높이 조절이 가능한 프레임은 다른 장비와 완벽하게 정렬할 수 있도록 도와줍니다.

주요 작업 기관: 이 기계의 핵심은 나선형 먼지 제거 경로에 동력을 공급하는 진동 본체입니다. 통합형 집진판과 진공 포트는 외부 진공 시스템에 연결되어 떨어져 나온 모든 먼지를 효율적으로 제거합니다.

밀봉된 외부 커버: 관찰창이 있는 완전 밀폐형 챔버는 교차 오염을 방지하고 전체 공정을 안전하게 모니터링할 수 있도록 합니다. 도구 없이 분해할 수 있도록 설계되어 세척이 빠르고 간편합니다.

태블릿 생산을 한 단계 끌어올릴 준비가 되셨나요? 오늘 견적을 받아보세요!

기계 세부 사항에 초점을 맞추다

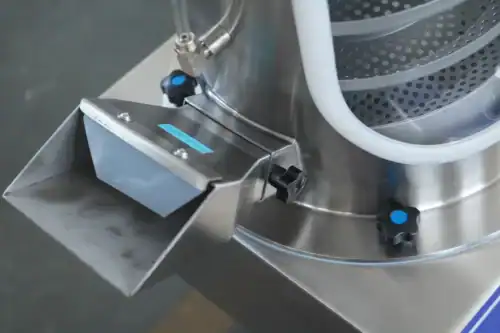

스크린 머신 콘센트

체질기 제어 손잡이

화면 내부 디스크

스크린 머신 공급 포트