การเคลือบเอนเทอริกคืออะไร — ประโยชน์ การใช้งาน และอุปกรณ์เคลือบ

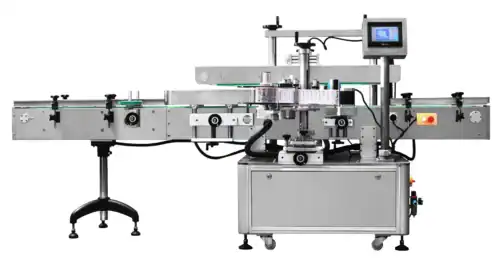

Grand Horizontal Labeling Machine Features – Grand Solutions

Grand’s advanced vertical-to-horizontal labeling machine is engineered for high-precision wrap-around labeling of cylindrical containers. It feeds bottles vertically and rotates them for horizontal labeling, making it ideal as a horizontal labeling machine for vials, syringes, small bottles, and pens. This versatile design addresses the labeling machine principle of precise positioning: as containers move on the conveyor, sensors trigger label dispensing, and dual-pressure rollers press labels smoothly with ±1 mm accuracy. By automating these steps, Grand’s system boosts throughput (10–200 bottles per minute, depending on size) and drastically cuts human error – studies show automatic labelers can reduce misplacement by ~70%.

Key components and innovations: Grand’s machine uses high-strength polyurethane synchronous belts in the wrap-around unit, offering durable, slip-resistant drive (far tougher than sponge belts) and quick, tool-less belt tension adjustment. An independent screw-feeding unit feeds small bottles steadily; it allows mold changes by swapping only the screw (no full disassembly) and even raises 80 mm for easy cleaning. The manual loading platform employs a wide slat-chain conveyor, buffering ~1,500 bottles so upstream equipment can run continuously, with anti-topple and breakage sensors for safety. A multi-axis adjustment base lets operators fine-tune label-head position (forward/back, lateral tilt) for new bottle sizes in seconds.

- Label Application Unit: A diamond-grit drive roller plus dual pressure rollers grip each label with high friction, preventing slippage and wrinkles during application. Unlike single-roller systems that risk tearing, the dual rollers ensure consistent slack and tension of the label web.

- Unwinding/Rewinding: Powered unwinder and rewinder stations automatically control tension (via swing-arms and sensors) to feed new labels and collect backing paper without slack or breakage. This guarantees uninterrupted labeling even at high speeds.

- การควบคุมที่แม่นยำ: Photoelectric sensors and servo stepper motors synchronize bottle spacing and label feeding. Grand’s GLA‑820 double-sided machine, for example, uses a dual-chain correction to center bottles and then applies labels on both sides simultaneouslygrandpackmachine.com. Operators can store up to 50 label setups on the touchscreen HMI, making changeovers nearly instantaneous.

With robust stainless-steel and anodized aluminum construction, Grand’s labeling machines meet cGMP requirements for medical labeling machines. They handle labels up to 120 mm high (unlimited length) with cores of 76 mm and roll OD <350 mm. The built-in labeling machine principle of using conveyor spacing, sensors, and press rollers is exactly what industry experts describe: bottles are separated and aligned, labels are printed (if needed) and peeled, then rollers flatten each label for a neat finishsed.

Precision Labeling for Vials and Small Bottles

Vertical-to-horizontal systems shine for vial labeling และ small bottle labeling, where containers cannot stand upright. As VKPAK notes, “horizontal transmission and labeling can help improve labeling accuracy and working efficiency” for small round bottles that can’t stand on their own. In practice, Grand’s machine accepts narrow containers (≥Ø10 mm with a simple mold change) and ensures full-wrap or partial labels fit perfectly around the circumference. For example, the machine can label 1 mL ampoules, 10 mL vials, insulin cartridges, and even auto-injector pens. This capability is critical in pharmaceutical and medical packaging, where traceability and legibility (barcodes, batch codes) are mandatory. Grand systems can integrate coders so that each vial’s label includes dates or serials as it’s applied.

Industries from cosmetics to chemicals also benefit. The machine’s ±1 mm accuracy and advanced sensors ensure each label is straight and bubble-free. Packaging experts report that automatic labelers achieve “millimeter-level precision” on cylindrical, flat, or conical containers, preserving brand appearance. By comparison, manual labeling is inconsistent and labor-intensive. Grand’s automation reduces staffing needs (studies cite up to 30% labor savings) and maintains 99%+ labeling quality. In short, whether labeling medication vials (medical labeling machine) or boutique essential oil bottles, the system maintains consistent placement and adhesion.

Integrated Filling and Capping in Automated Lines

Grand’s labeling machines are designed to work in concert with Grand filling and capping machines, forming turnkey production lines. In a typical setup, bottles are first filled by a precision dosing machine, capped, then arrive at the labeler for final branding and regulatory labels. For example, the Grand ZHG‑50 is an automatic cream filling and capping machine that handles cosmetics or pharmaceutical creams at up to 40 bottles/min with filling and capping accuracy ≥99%. Its specifications (5–200 g fill, 2 kW motor, ±1 mm labeling precision) complement the labeling stage. Another model, the ZHJY‑50 filling & capping unit, uses PLC control and automatically stops if no bottles are detected. These machines seamlessly feed into the Grand labeling line.

Packaging machinery leaders emphasize that a complete packaging line is a “coordinated set of machines” – typically a filler, a capper, and a labeler – linked by conveyors. CDA Packaging notes this combination “transforms a raw or semi-finished product into a finished product,” improving throughput and consistency. By pairing Grand’s horizontal labeling machine with compatible cappers and fillers, companies achieve a fully automated labeling machine combination that requires minimal manual intervention. For instance, after bottles are filled and sealed by Grand equipment, they enter the horizontal labeler. The result is a regulated, high-speed สายการผลิต where each container is dose-filled, securely capped, and precisely labeled with minimal downtime.

Applications of such lines abound: pharmaceutical plants can automatically label vials and syringes with exact dosage labels; cosmetics manufacturers can run lotions or shampoo filling and then label each bottle in one flow; food producers can fill sauces or essential oils and wrap labels in the same line. In all cases, integrated lines maximize efficiency: CDA notes benefits like “consistent quality (accurate dosing, perfectly aligned labeling, secure closures)” and “optimized production time” from continuous operation. By contrast, stand-alone or manual equipment would create bottlenecks. Grand’s holistic approach – designing labeling machines that easily slot into filling/capping lines – reflects modern “labeling machine application” strategies for automated packaging.

Why Choose Grand’s Labeling Systems?

Grand Machinery brings decades of experience to labeling technology. As their GLA‑820 machine brochure explains, every labeling system is built for durability and operator ease. Premium components (like Japanese Omron sensors and Sanyo motors) and rigorous quality checks ensure minimal downtime. Intuitive controls let operators save up to 50 product recipes and switch formats with one touch.

Global industry customers trust Grand’s equipment. VialLabeller – a leading horizontal labeling supplier – reports over 18 years in business and shipments to 60+ countries, a testament to international confidence in these systems. Furthermore, Grand’s machines conform to FDA and EU regulatory demands for medical labeling machines by using FDA-approvable materials and offering precise traceability. Quality control is integral: sensors can detect missing labels or print errors and reject faulty items, preserving brand integrity. This focus on trustworthiness is echoed by packaging experts: “consistent performance and quality” are vital, especially in pharmaceuticals.

In summary, Grand’s vertical-to-horizontal labeling machine offers an expert-engineered solution for any industry needing high-speed, high-precision labeling. Its innovative design (vertical feed, horizontal wrap), robust features (PU belts, dual rollers, automatic tension control), and seamless integration with Grand’s filling/capping units make it a top choice. By adopting this system, manufacturers gain faster production, fewer labeling errors, and a partner with proven authority in packaging automation.

อ้างอิง:

- Pharma. Round Bottle Labeling Machine. (Describes conveyor, sensor, and labeling principle)sedpharma.comsedpharma.com.

- Grandpack Machine. เครื่องติดฉลากสองด้าน GLA-820. (Specs, operation, and advantages of Grand’s labeling systems).

- Viallabeller. Automatic Horizontal Labeling Machine. (Overview of horizontal labeling for pharma containers; precision features).

- VKPAK. Small Bottle Labeling Machine. (Horizontal vs. vertical labeling methods for vials; performance specs).

- CDA Packaging USA. Automatic Labeling Machines: Key Features and Benefits. (Benefits of automation: precision, speed, error reduction).

- USA. Packaging Line: From Modular Solutions to Complete Systems. (Integrated filling-capping-labeling line design and advantages)cda-usa.com.