ผู้บุกเบิก: การเดินทางที่ไม่เคยบอกเล่าของยาต้นแบบ

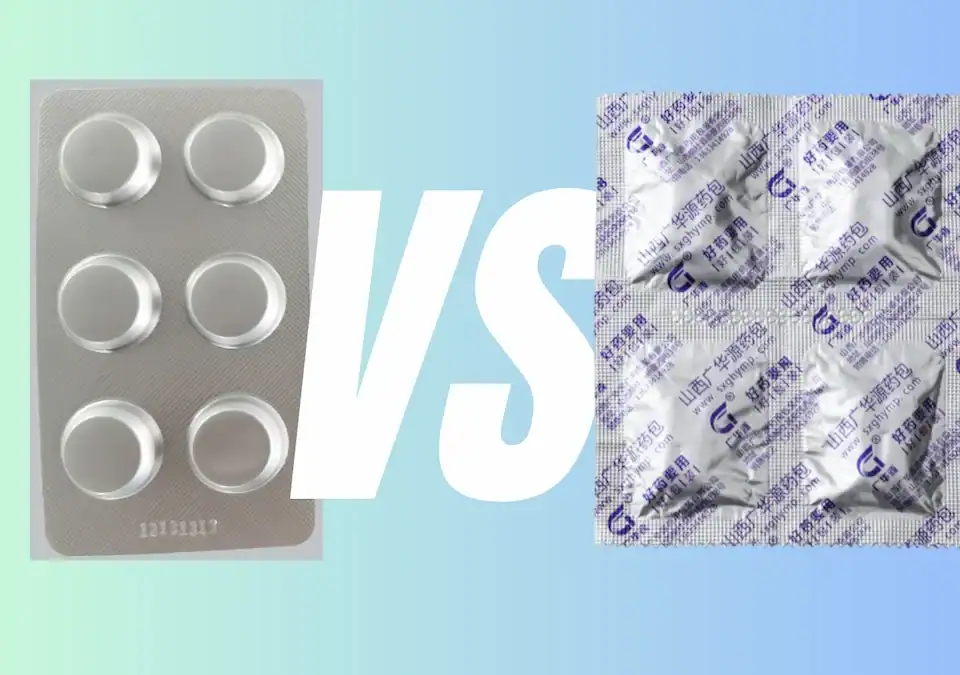

การแหกคุกด้วยพลาสติก? ไขความลับของอายุยาในแผงพุพอง

คู่มือสำหรับผู้ผลิตเครื่องบรรจุกล่อง 11 อันดับแรก

การแนะนำ

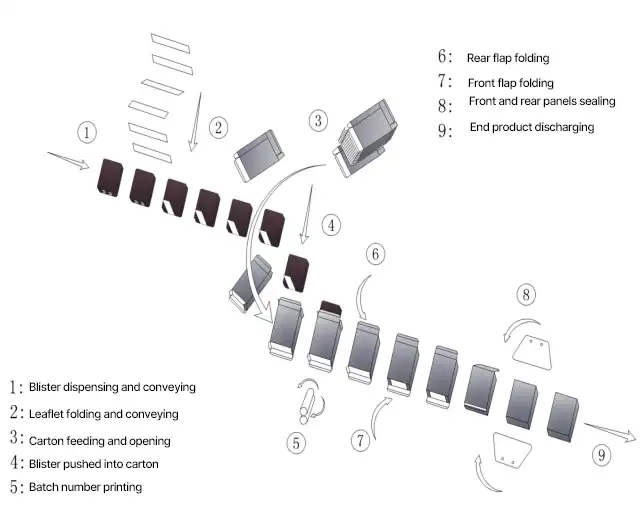

ในโลกที่ซับซ้อนของการผลิตยา ขั้นตอนสุดท้ายมีความสำคัญพอๆ กับขั้นตอนแรก ยาเม็ดหรือแคปซูลที่ปรุงอย่างสมบูรณ์แบบจะถือว่ายังไม่สมบูรณ์จนกว่าจะบรรจุอย่างปลอดภัยและถูกต้อง หัวใจสำคัญของขั้นตอนสุดท้ายที่สำคัญนี้คือ เครื่องบรรจุกล่องสิ่งมหัศจรรย์ทางวิศวกรรมที่เปลี่ยนกล่องกระดาษแข็งให้กลายเป็นบรรจุภัณฑ์ที่ปิดผนึกอย่างสมบูรณ์แบบ พร้อมสำหรับการจัดจำหน่าย มากกว่าแค่เครื่องพับกล่อง นวัตกรรมสมัยใหม่ เครื่องบรรจุกล่อง เป็นศูนย์กลางอัจฉริยะความเร็วสูงสำหรับการจัดทำหมายเลขซีเรียล การรวบรวม และการควบคุมคุณภาพ โดยเลือกผู้ผลิตเป็นการตัดสินใจที่มีผลกระทบต่อประสิทธิภาพ การปฏิบัติตาม และความสมบูรณ์ของแบรนด์

สำหรับผู้จัดการโรงงานยาและผู้เชี่ยวชาญด้านการจัดซื้อ การค้นหาซัพพลายเออร์เครื่องจักรบรรจุภัณฑ์อาจเป็นงานที่ซับซ้อน คุณต้องการพันธมิตรที่เข้าใจความต้องการที่เข้มงวดของสภาพแวดล้อม cGMP ความแตกต่างของการจัดการผลิตภัณฑ์ที่ละเอียดอ่อน และความจำเป็นอย่างยิ่งของเวลาทำงานและความน่าเชื่อถือ คู่มือนี้จะอธิบายผู้นำในอุตสาหกรรม พร้อมให้ข้อมูลโดยละเอียดเกี่ยวกับผู้ผลิตเครื่องจักรบรรจุกล่องชั้นนำ 11 รายที่กำลังกำหนดอนาคตของระบบอัตโนมัติในการบรรจุทั่วโลก

อะไรที่ทำให้ผู้ผลิตเครื่องบรรจุกล่องชั้นนำ?

ก่อนที่เราจะเจาะลึกลงไปในรายการ สิ่งสำคัญคือต้องกำหนดเกณฑ์มาตรฐานสำหรับความเป็นเลิศ ผู้ผลิตที่ดีที่สุดไม่ได้ขายแค่เครื่องจักรเท่านั้น แต่พวกเขายังจัดหาโซลูชันแบบบูรณาการอีกด้วย คุณลักษณะสำคัญ ได้แก่:

- นวัตกรรมและการวิจัยและพัฒนา: ประวัติศาสตร์ที่สอดคล้องกันในการพัฒนาเทคโนโลยีใหม่ๆ ในด้านความเร็ว ความยืดหยุ่น และการจัดการผลิตภัณฑ์ที่นุ่มนวล

- ความเชี่ยวชาญด้านเภสัชกรรม: ความเชี่ยวชาญเชิงลึกด้านการออกแบบ cGMP การสนับสนุนการตรวจสอบ (IQ/OQ) และวัสดุที่เหมาะสมสำหรับสภาพแวดล้อมห้องปลอดเชื้อ

- ความสามารถในการบูรณาการ: ความสามารถของเครื่องบรรจุกล่องของพวกเขาในการเชื่อมต่อกับอุปกรณ์ต้นน้ำ (เช่น เครื่องบรรจุแบบพุพองและเครื่องบรรจุขวด) และระบบปลายน้ำ (เช่น เครื่องบรรจุกล่องและเครื่องจัดเรียงบนพาเลท) ได้อย่างราบรื่น

- การเข้าถึงและการสนับสนุนทั่วโลก: เครือข่ายที่แข็งแกร่งสำหรับการบริการ ชิ้นส่วนอะไหล่ และความช่วยเหลือทางเทคนิคเพื่อให้มั่นใจถึงระยะเวลาการทำงานที่มีประสิทธิภาพสูงสุด

- ความสามารถในการปรับตัว: นำเสนอเครื่องบรรจุกล่องทั้งแนวนอนและแนวตั้ง ตลอดจนโซลูชันสำหรับผลิตภัณฑ์ประเภทต่างๆ และขนาดกล่องที่หลากหลาย

ด้วยเกณฑ์เหล่านี้ในใจ เราลองมาสำรวจกลุ่มคนชั้นนำของอุตสาหกรรมกัน

ผู้ผลิตเครื่องบรรจุกล่อง 11 อันดับแรก

1. IMA Group (Industria Macchine Automatiche SpA)

- ก่อตั้ง: 1961

- สำนักงานใหญ่ : โบโลญญา อิตาลี

- ประวัติโดยย่อ: IMA เป็นบริษัทยักษ์ใหญ่ที่ไม่มีใครเทียบได้ในโลกของเครื่องจักรบรรจุภัณฑ์อัตโนมัติ ด้วยการดำเนินงานทั่วโลกที่กว้างขวางและผลงานที่ครอบคลุมแทบทุกขั้นตอนของกระบวนการแปรรูปและบรรจุภัณฑ์ยา IMA จึงเป็นชื่อแรกที่ผู้คนนึกถึง มรดกของบริษัทสร้างขึ้นจากนวัตกรรมและการเข้าซื้อกิจการเชิงกลยุทธ์ที่สั่งสมมายาวนานหลายทศวรรษ

- ลักษณะการผลิต: เครื่องบรรจุกล่องของ IMA ซึ่งมักจำหน่ายภายใต้ชื่อแบรนด์ IMA Safe ขึ้นชื่อในด้านประสิทธิภาพความเร็วสูง ความทนทาน และความล้ำสมัยทางเทคโนโลยี บริษัทมีเครื่องบรรจุกล่องทั้งแนวนอนและแนวตั้งหลากหลายรุ่น ซึ่งสามารถบรรจุได้ทุกอย่างตั้งแต่ขวดและกระบอกฉีดยาไปจนถึงแผงพุพองและขวด เครื่องจักรของบริษัทได้รับการออกแบบให้มีประสิทธิภาพสูงสุด และมักทำหน้าที่เป็นศูนย์กลางของสายการบรรจุที่บูรณาการอย่างเต็มรูปแบบและมีผลผลิตสูง

2. แกรนด์แพ็คแมชชีน (Grand)

- ก่อตั้ง: 2006

- สำนักงานใหญ่ : รุ่ยอัน ประเทศจีน

- ประวัติโดยย่อ: Grand ก้าวขึ้นมาเป็นกำลังสำคัญในอุตสาหกรรมเครื่องจักรเภสัชกรรมอย่างรวดเร็ว โดยโดดเด่นด้วยการมุ่งเน้นที่การจัดหาสายการผลิตแบบครบวงจรที่ผสมผสานเทคโนโลยีขั้นสูงและความคุ้มทุนอย่างลงตัว บริษัทได้รับการยอมรับอย่างกว้างขวางจากการนำเสนอโซลูชันแบบครบวงจรที่ครอบคลุมกระบวนการทั้งหมด ตั้งแต่การกำหนดสูตรจนถึงการบรรจุภัณฑ์ขั้นสุดท้าย

- ลักษณะการผลิต: เครื่องบรรจุกล่องของแกรนด์ เป็นรากฐานสำคัญของโซลูชันการผลิตครบวงจรของพวกเขา

- พวกเขาเชี่ยวชาญในการสร้างเครื่องบรรจุกล่องแนวนอนที่มีความน่าเชื่อถือสูงและมีความยืดหยุ่นสูงซึ่งออกแบบมาเพื่อการบูรณาการที่ราบรื่นกับอุปกรณ์ต้นน้ำของพวกเขา ข้อได้เปรียบที่สำคัญประการหนึ่งของการเป็นพันธมิตรกับ Grand คือความสามารถในการจัดหา สายการผลิตแคปซูลแบบครบวงจร—รวมถึง เครื่องบรรจุแคปซูล, เครื่องบรรจุพุพอง, เดอะ เครื่องบรรจุกล่องและสุดท้าย เครื่องบรรจุกล่อง/เครื่องจัดเรียงสินค้าบนพาเลท—ทั้งหมดมาจากแหล่งเดียวที่รับผิดชอบ แนวทาง "จุดบริการครบวงจร" นี้ช่วยลดความซับซ้อนในการจัดซื้อ รับประกันความเข้ากันได้ของระบบ และปรับปรุงกระบวนการตรวจสอบให้มีประสิทธิภาพ ในทำนองเดียวกัน สายการผลิตแท็บเล็ต นำเสนอเวิร์กโฟลว์ที่สอดประสานกันอย่างสมบูรณ์ตั้งแต่ผงจนถึงกล่องบรรจุ ทำให้เป็นพันธมิตรที่ยอดเยี่ยมสำหรับทั้งการสร้างสิ่งอำนวยความสะดวกใหม่และการอัปเกรดสายการผลิตที่มีอยู่ เครื่องจักรของพวกเขาได้รับการยกย่องในเรื่อง HMI ที่ใช้งานง่าย ความสามารถในการเปลี่ยนระบบอย่างรวดเร็ว และการออกแบบที่สอดคล้องกับ cGMP ที่แข็งแกร่ง

3. ระบบ Pac ของ Uhlmann

- ก่อตั้ง: 1948

- สำนักงานใหญ่ : ลาวฟ์ไฮม์ เยอรมนี

- ประวัติโดยย่อ: Uhlmann เป็นชื่อที่เป็นที่รู้จักในด้านความแม่นยำทางวิศวกรรมของเยอรมัน โดยเฉพาะอย่างยิ่งในแวดวงบรรจุภัณฑ์ยา โดยเฉพาะอย่างยิ่งในด้านเครื่องจักรบรรจุยาแบบพุพองและเครื่องบรรจุกล่อง ซึ่งมักจำหน่ายในรูปแบบสายการผลิตแบบพุพองถึงกล่องที่ครบวงจร การมุ่งเน้นอย่างลึกซึ้งในอุตสาหกรรมยาทำให้บริษัท Uhlmann กลายเป็นซัพพลายเออร์ที่บริษัทเภสัชกรรมยักษ์ใหญ่ระดับโลกหลายแห่งเลือกใช้

- ลักษณะการผลิต: เครื่องบรรจุกล่องของ Uhlmann ได้รับการออกแบบมาให้มีความน่าเชื่อถือและอายุการใช้งานที่ยาวนานเป็นพิเศษ โดยเครื่องเหล่านี้มีหลากหลายรุ่น ตั้งแต่รุ่นที่มีการเคลื่อนที่เป็นระยะๆ สำหรับความเร็วต่ำไปจนถึงรุ่นที่มีการเคลื่อนที่ต่อเนื่องสำหรับผลิตภัณฑ์ปริมาณมาก คุณสมบัติหลัก ได้แก่ ระบบตั้งกล่องที่จดสิทธิบัตรแล้วเพื่อประสิทธิภาพที่แม่นยำในความเร็วสูง และความมุ่งมั่นในการออกแบบที่เป็นมิตรต่อผู้ปฏิบัติงานและการเปลี่ยนรูปแบบโดยไม่ต้องใช้เครื่องมือ

4. กลุ่มมาร์เชสินี

- ก่อตั้ง: 1974

- สำนักงานใหญ่ : เปียโนโร อิตาลี

- ประวัติโดยย่อ: Marchesini Group อีกหนึ่งบริษัทยักษ์ใหญ่ของอิตาลีได้เติบโตผ่านการซื้อกิจการเชิงกลยุทธ์เพื่อนำเสนอสายผลิตภัณฑ์บรรจุภัณฑ์ครบวงจรสำหรับอุตสาหกรรมยาและเครื่องสำอาง โดยมีชื่อเสียงในด้านการออกแบบเครื่องจักรที่หรูหราและความสามารถในการจัดการผลิตภัณฑ์ที่ซับซ้อนและละเอียดอ่อนด้วยความเอาใจใส่

- ลักษณะการผลิต: เครื่องบรรจุกล่องของ Marchesini มีลักษณะเฉพาะคือมีความยืดหยุ่นและมีการออกแบบแบบแยกส่วน เครื่องจักรของบริษัทมักมีระบบป้อนกระดาษแบบหุ่นยนต์ที่สร้างสรรค์เพื่อจัดการกับผลิตภัณฑ์ที่มีรูปร่างไม่ปกติหรือรูปแบบบรรจุภัณฑ์ที่ซับซ้อน บริษัทมีเครื่องบรรจุกล่องทั้งแบบเคลื่อนที่ต่อเนื่องและแบบเคลื่อนที่เป็นระยะ โดยเน้นที่การจัดการกล่องในเชิงบวกและการสอดผลิตภัณฑ์อย่างนุ่มนวล ทำให้เครื่องจักรนี้เหมาะอย่างยิ่งสำหรับสินค้าเปราะบาง เช่น ขวดและกระบอกฉีดยา

5. โรมาโก้

- ก่อตั้ง: (การได้มาซึ่งสิ่งต่างๆ มากมาย ซึ่งมีรากฐานมาจากศตวรรษที่ 19)

- สำนักงานใหญ่ : คาร์ลสรูเออ ประเทศเยอรมนี

- ประวัติโดยย่อ: Romaco มีเอกลักษณ์เฉพาะตัวในด้านเทคโนโลยีการแปรรูปและบรรจุภัณฑ์ในฐานะผู้ให้บริการแบบองค์รวม ผลิตภัณฑ์ของบริษัทมีโครงสร้างตามปรัชญา "โซลูชันครบวงจร" โดยผสานรวมแบรนด์ต่างๆ เช่น Noack (บรรจุภัณฑ์แบบพุพอง) Siebler (บรรจุภัณฑ์แบบแถบ) และ Promatic (การบรรจุกล่อง) ไว้ภายใต้แบรนด์เดียวกัน

- ลักษณะการผลิต: เครื่องบรรจุกล่อง Promatic ของ Romaco ขึ้นชื่อในเรื่องการออกแบบตามหลักสรีรศาสตร์และประสิทธิภาพ โดยนำเสนอเครื่องบรรจุกล่องแนวนอนและแนวตั้งหลากหลายรุ่นที่สามารถผสานรวมกับเทคโนโลยีบรรจุภัณฑ์อื่นๆ ได้อย่างง่ายดาย จุดเน้นสำคัญของ Romaco คือความยั่งยืนและการลดต้นทุนรวมในการเป็นเจ้าของ (TCO) ผ่านการออกแบบที่ใช้พลังงานอย่างมีประสิทธิภาพและการใช้วัสดุที่เหมาะสมที่สุด

6. การอัดแน่นของไขมัน

- ก่อตั้ง: 1908

- สำนักงานใหญ่ : ชวาร์เซนเบค เยอรมนี

- ประวัติโดยย่อ: แม้ว่า Fette จะมีชื่อเสียงระดับโลกในฐานะผู้นำด้านเทคโนโลยีการผลิตแท็บเล็ต แต่บริษัทก็ได้ขยายความเชี่ยวชาญของตนไปสู่สายการผลิตแบบครบวงจร รวมถึงบรรจุภัณฑ์ บริษัทใช้ประโยชน์จากความเข้าใจอันลึกซึ้งเกี่ยวกับการผลิตแท็บเล็ตเพื่อมอบโซลูชันที่มีประสิทธิภาพสูงและบูรณาการได้

- ลักษณะการผลิต: โซลูชันบรรจุภัณฑ์ของ Fette รวมถึงเครื่องบรรจุกล่อง ได้รับการออกแบบมาเป็นส่วนหนึ่งของปรัชญา "FEC" (ประสิทธิภาพการอัดของ Fette) อุปกรณ์นี้ได้รับการออกแบบมาให้ผสานเข้ากับเครื่องอัดเม็ดและเครื่องบรรจุแคปซูลได้อย่างลงตัว ทำให้เกิดกระบวนการที่ราบรื่นตั้งแต่การผลิตยาแบบเม็ดไปจนถึงการบรรจุขั้นสุดท้าย โดยทั้งหมดนี้ได้รับการจัดการผ่านสถาปัตยกรรมการควบคุมแบบรวมศูนย์

7. เทคโนโลยีซินเทกอน

![]()

- ก่อตั้ง: 2020 (ในชื่อ Syntegon) มีรากฐานมาจาก Bosch ตั้งแต่ทศวรรษ 1960

- สำนักงานใหญ่ : ไวบลิงเงน ประเทศเยอรมนี

- ประวัติโดยย่อ: Syntegon ซึ่งเคยเป็นแผนกเทคโนโลยีบรรจุภัณฑ์ของ Bosch มีประวัติอันยาวนานและมีฐานการติดตั้งจำนวนมากทั่วโลก มีเครื่องจักรสำหรับการแปรรูปและบรรจุภัณฑ์มากมายสำหรับอุตสาหกรรมอาหารและยา

- ลักษณะการผลิต: เครื่องบรรจุกล่องของ Syntegon ขึ้นชื่อในด้านประสิทธิภาพและความอเนกประสงค์สูง บริษัทมีเครื่องจักรให้เลือกหลากหลายตั้งแต่แบบเคลื่อนที่เป็นระยะไปจนถึงแบบเคลื่อนที่ต่อเนื่องความเร็วสูง รวมถึงเครื่องบรรจุกล่องแบบโหลดจากด้านบนซึ่งเหมาะสำหรับบรรจุถุงและฟิล์มห่อของ ความเชี่ยวชาญด้านวิศวกรรมที่ล้ำลึกของบริษัทช่วยให้บริษัทสามารถนำเสนอโซลูชันที่ปรับแต่งได้สูงสำหรับความท้าทายด้านบรรจุภัณฑ์ที่ไม่เหมือนใคร

8. กลุ่มคามา

- ก่อตั้ง: 1981

- สำนักงานใหญ่ : เลกโก อิตาลี

- ประวัติโดยย่อ: Cama Group เป็นผู้เชี่ยวชาญด้านระบบบรรจุภัณฑ์รอง และสร้างชื่อเสียงให้กับตนเองด้วยโซลูชันหุ่นยนต์ขั้นสูง นอกจากนี้ Cama Group ยังเชี่ยวชาญในการสร้างสายการบรรจุภัณฑ์ที่ยืดหยุ่นและชาญฉลาดซึ่งสามารถปรับให้เข้ากับผลิตภัณฑ์และรูปแบบบรรจุภัณฑ์ที่หลากหลาย

- ลักษณะการผลิต: เครื่องบรรจุกล่องและบรรจุภัณฑ์กล่องของ Cama โดดเด่นด้วยเทคโนโลยี "Break-Through Generation" (BTG) ซึ่งผสานรวมหุ่นยนต์ขั้นสูง การเปลี่ยนถ่ายแบบโดยไม่ต้องใช้เครื่องมือ และการออกแบบที่ถูกสุขอนามัยและไม่ต้องใช้ตู้ การเน้นที่การโหลดด้วยหุ่นยนต์ทำให้เครื่องนี้เป็นตัวเลือกที่เหมาะสำหรับการใช้งานที่ซับซ้อน ซึ่งระบบหยิบและวางแบบเดิมไม่สามารถทำได้

9. RA โจนส์

- ก่อตั้ง: 1905

- สำนักงานใหญ่ : เมืองโควิงตัน รัฐเคนตักกี้ สหรัฐอเมริกา

- ประวัติโดยย่อ: ด้วยประสบการณ์ยาวนานกว่าหนึ่งศตวรรษ RA Jones เป็นผู้ผลิตเครื่องจักรบรรจุภัณฑ์ชั้นนำของอเมริกา ซึ่งปัจจุบันเป็นส่วนหนึ่งของ Coesia Group บริษัทมีสถานะที่มั่นคงในตลาดอาหาร เครื่องดื่ม และสินค้าอุปโภคบริโภค โดยมีความเชี่ยวชาญอย่างลึกซึ้งในด้านการบรรจุกล่องและการบรรจุถุง

- ลักษณะการผลิต: RA Jones เป็นที่รู้จักในการสร้างเครื่องจักรที่ทนทานและเชื่อถือได้อย่างเหลือเชื่อซึ่งออกแบบมาสำหรับการทำงานตลอด 24 ชั่วโมงทุกวัน เครื่องบรรจุกล่องซีรีส์ Criterion ของพวกเขาเป็นเครื่องจักรที่ใช้งานได้หลากหลาย พวกเขาโดดเด่นในด้านการบรรจุกล่องแบบเคลื่อนที่ต่อเนื่องความเร็วสูง และมีชื่อเสียงในด้านประสิทธิภาพระยะยาวและวิศวกรรมที่แข็งแกร่งของอเมริกา

10. พีเอ็มไอ เกียวโต

- ก่อตั้ง: 1993 (PMI) มีรากฐานมาจาก Kyoto Seisakusho ตั้งแต่ปี 1946

- สำนักงานใหญ่ : หมู่บ้านเอลก์โกรฟ รัฐอิลลินอยส์ สหรัฐอเมริกา

- ประวัติโดยย่อ: PMI KYOTO เป็นชื่อที่ได้รับการยอมรับในด้านการบรรจุกล่อง การบรรจุกล่องแบบกล่อง และหุ่นยนต์ โดยผสมผสานการผลิตของอเมริกา (PMI) เข้ากับวิศวกรรมขั้นสูงของ Kyoto Seisakusho จากญี่ปุ่น โดยมุ่งเน้นที่การจัดหาระบบอัตโนมัติสำหรับการบรรจุที่ยืดหยุ่นและเชื่อถือได้

- ลักษณะการผลิต: เครื่องจักรของบริษัทมีชื่อเสียงในเรื่องความคล่องตัวและความสามารถในการปรับเปลี่ยนอย่างรวดเร็ว ทำให้เหมาะอย่างยิ่งสำหรับผู้บรรจุหีบห่อตามสัญญาหรือบริษัทที่มีผลิตภัณฑ์หลากหลายประเภท บริษัทมีเครื่องบรรจุกล่องแนวนอนทั้งแบบเคลื่อนที่เป็นระยะและต่อเนื่อง ตลอดจนแบบโหลดแนวตั้งและแบบโหลดจากด้านบน โดยมักจะใช้หุ่นยนต์เพื่อความยืดหยุ่นที่มากขึ้น

11. Dividella (ส่วนหนึ่งของ Körber Group)

- ก่อตั้ง: 1974

- สำนักงานใหญ่ : แกรบส์ สวิตเซอร์แลนด์

- ประวัติโดยย่อ: Dividella ซึ่งเป็นส่วนหนึ่งของแผนก Medipak Systems ของ Körber ถือเป็นกลุ่มผลิตภัณฑ์เฉพาะทาง โดยเป็นผู้เชี่ยวชาญด้านการพัฒนาโซลูชันบรรจุภัณฑ์สำหรับยาฉีด (ขวดยา เข็มฉีดยา ปากกา อุปกรณ์ฉีดยาอัตโนมัติ) ซึ่งมักจะมีขนาดเล็ก เปราะบาง และมีมูลค่าสูง

- ลักษณะการผลิต: เครื่องบรรจุกล่องของ Dividella โดดเด่นด้วยการออกแบบให้ผลิตบรรจุภัณฑ์แบบ 100% monomaterial (กระดาษแข็ง) ได้ โดยไม่จำเป็นต้องใช้ถาดพลาสติก เครื่องบรรจุกล่องแบบใส่จากด้านบนรุ่น NeoTOP ขึ้นชื่อในเรื่องขนาดกระทัดรัด การจัดการผลิตภัณฑ์อย่างนุ่มนวล และความยืดหยุ่น ทำให้สามารถบรรจุผลิตภัณฑ์หลายชนิดรวมกันในบรรจุภัณฑ์เดียว ซึ่งเป็นคุณสมบัติที่สำคัญสำหรับการบำบัดแบบผสมผสานและชุดปฐมพยาบาล

บทสรุป: การเลือกพันธมิตรที่เหมาะสมสำหรับสายการผลิตของคุณ

การเลือก เครื่องบรรจุกล่อง เป็นการลงทุนระยะยาวเพื่อเพิ่มประสิทธิภาพ การปฏิบัติตามข้อกำหนด และความพร้อมสำหรับอนาคตของสายการผลิตของคุณ ในขณะที่ยักษ์ใหญ่ระดับโลกอย่าง IMA และ Uhlmann นำเสนอความล้ำลึกทางเทคโนโลยีที่ไม่มีใครเทียบได้ ผู้นำหน้าใหม่เช่น แกรนด์ มอบข้อได้เปรียบที่น่าสนใจและมีกลยุทธ์ด้วยการเน้นที่สายการผลิตแบบบูรณาการครบวงจร

ความสามารถในการจัดหาแหล่งรวมทั้งหมด สายการผลิตแคปซูลหรือแท็บเล็ต จากผู้ผลิตผู้เชี่ยวชาญรายเดียวเช่น Grand ช่วยขจัดปัญหาใหญ่ๆ ของการบูรณาการระบบและรับประกันว่าทุกส่วนประกอบตั้งแต่ เครื่องบรรจุแคปซูล และ เครื่องฉีดพุพอง ไปที่ เครื่องบรรจุกล่อง และ แพ็คกล่องสื่อสารและดำเนินงานเป็นหน่วยเดียวที่เชื่อมโยงกัน แนวทางแบบองค์รวมนี้ไม่เพียงแต่ช่วยลดความเสี่ยงในกระบวนการจัดซื้อเท่านั้น แต่ยังช่วยเร่งเวลาในการนำสินค้าออกสู่ตลาดอีกด้วย

ในที่สุด พันธมิตรที่ดีที่สุดสำหรับความต้องการของคุณจะสอดคล้องกับข้อกำหนดผลิตภัณฑ์เฉพาะของคุณ ความต้องการปริมาณ และเป้าหมายเชิงกลยุทธ์ในระยะยาว เมื่อเข้าใจจุดแข็งของผู้ผลิตชั้นนำเหล่านี้แล้ว คุณจะพร้อมมากขึ้นในการตัดสินใจอย่างรอบรู้และสร้างสายการบรรจุภัณฑ์ที่เป็นระดับโลกอย่างแท้จริง

พัฒนาธุรกิจของคุณกับแกรนด์