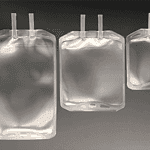

คู่มือแนะนำผู้ผลิตสายการผลิตถุง IV ชั้นนำ 11 รายสำหรับปี 2025

เครื่องบรรจุหลอด NF-150: เจาะลึกเทคโนโลยีการใช้งานคู่

เครื่องบรรจุของเหลวในช่องปากสามารถบรรจุอะไรได้บ้าง?

การแนะนำ

เมื่อคุณได้ยินคำว่า เครื่องบรรจุของเหลวในช่องปากจิตใจของคุณอาจกระโดดไปที่แอปพลิเคชันเฉพาะหนึ่งรายการ: บรรจุภัณฑ์ยาแม้ว่าคุณจะไม่ได้คิดผิด แต่คุณกำลังมองเห็นเพียงส่วนเล็กๆ ของภูเขาน้ำแข็ง เครื่องบรรจุของเหลวสำหรับรับประทานสมัยใหม่คือความมหัศจรรย์ของเทคโนโลยีบรรจุภัณฑ์ เป็นเครื่องจักรอเนกประสงค์ที่มีความสามารถเหนือกว่าอุตสาหกรรมยา มันคือโซลูชันแบบบูรณาการที่ทำให้กระบวนการทั้งหมดตั้งแต่การขึ้นรูปภาชนะบรรจุ การบรรจุผลิตภัณฑ์ และการปิดผนึกเป็นไปโดยอัตโนมัติ ทำให้เหมาะอย่างยิ่งสำหรับสิ่งที่เรียกกันในอุตสาหกรรมว่า "การบรรจุแบบครั้งเดียว" หรือการบรรจุแบบโดสต่อหน่วย

เครื่องจักรเหล่านี้ได้รับการออกแบบทางวิศวกรรมเพื่อความแม่นยำ สุขอนามัย และประสิทธิภาพ ทำให้เป็นตัวเลือกที่สมบูรณ์แบบสำหรับผลิตภัณฑ์ที่หลากหลายอย่างน่าประหลาดใจ ตั้งแต่เครื่องดื่มที่คุณดื่ม อาหารที่คุณรับประทาน เครื่องสำอางที่คุณใช้ ไปจนถึงอาหารเสริมเพื่อสุขภาพที่คุณรับประทาน การใช้งานนั้นแทบจะไร้ขีดจำกัด เทคโนโลยีนี้กำลังปฏิวัติวิธีที่บริษัทต่างๆ จัดการกับบรรจุภัณฑ์แบบเสิร์ฟครั้งเดียว นำเสนอโซลูชันที่มีของเสียต่ำและสะดวกสบายสูงสำหรับผู้บริโภคในปัจจุบัน

มาสำรวจโลกอันกว้างใหญ่และหลากหลายของผลิตภัณฑ์ที่สามารถจัดการได้อย่างเชี่ยวชาญด้วยอุปกรณ์อันน่าทึ่งชิ้นนี้

เครื่องบรรจุของเหลวในช่องปากคืออะไรกันแน่?

ก่อนที่เราจะเจาะลึกถึงการใช้งานจริง เรามาทำความเข้าใจกันก่อนว่าเครื่องจักรนี้คืออะไรและทำหน้าที่อะไร หลักการทำงานของมันคือเครื่องจักรขึ้นรูป-บรรจุ-ปิดผนึกอัตโนมัติ (FFS) กระบวนการนี้เป็นการทำงานแบบ all-in-one ที่ราบรื่น เกิดขึ้นบนสายการผลิตเดียว

ต่อไปนี้เป็นรายละเอียดง่าย ๆ ของวิธีการทำงาน:

- การขึ้นรูป: เครื่องจักรนี้ใช้ม้วนฟิล์มคอมโพสิต ซึ่งโดยทั่วไปจะเป็นฟิล์มผสม PVC/PE หรือ PET/PE และใช้ความร้อนและแรงดันอากาศเพื่อขึ้นรูปเป็นขวดหรือภาชนะพลาสติกที่มีรูปร่างตามต้องการ

- ไส้: จากนั้นจะใช้ปั๊มที่มีความแม่นยำสูง ซึ่งมักเป็นปั๊มลูกสูบอิเล็กทรอนิกส์หรือปั๊มลูกสูบเชิงกล เพื่อเติมผลิตภัณฑ์ของเหลวหรือกึ่งของเหลวในปริมาณที่ตั้งไว้ล่วงหน้าอย่างแม่นยำลงในภาชนะแต่ละใบ

- การปิดผนึก: ในที่สุด เครื่องจะทำการปิดผนึกด้านบนของภาชนะด้วยความร้อน สร้างรูพรุนหรือรอยบากตามความจำเป็น และตัดหน่วยที่เสร็จแล้วออกจากกัน

การดำเนินงานทั้งหมดได้รับการออกแบบให้มีประสิทธิภาพ มีขนาดเล็กและต้นทุนการลงทุนต่ำ จึงเป็นตัวเลือกที่เหมาะสำหรับธุรกิจที่ต้องการนำโซลูชันบรรจุภัณฑ์ที่สะอาดและทันสมัยมาใช้ รุ่นขั้นสูงถูกสร้างขึ้นให้ตรงตามมาตรฐาน GMP (Good Manufacturing Practice) ที่เข้มงวด ชิ้นส่วนสัมผัสผลิตภัณฑ์ทำจากสเตนเลสสตีล 316L คุณภาพสูง และตัวเครื่องทำจากสเตนเลสสตีล SUS304 ความมุ่งมั่นด้านสุขอนามัยนี้ทำให้ปลอดภัยสำหรับใช้กับอาหาร ยา และเครื่องสำอาง

แอพพลิเคชั่นที่หลากหลาย

จุดแข็งที่แท้จริงของเครื่องจักรนี้อยู่ที่ความสามารถในการปรับตัว การผสมผสานระหว่างระบบการบรรจุที่แม่นยำและความสามารถในการรองรับของเหลวที่มีความหนืดหลากหลาย เปิดประตูสู่หลากหลายอุตสาหกรรม เอกสารอย่างเป็นทางการสำหรับเครื่องจักรเหล่านี้แสดงรายการการใช้งาน รวมถึง

ยา เครื่องดื่ม ผลิตภัณฑ์นม ผลิตภัณฑ์เพื่อสุขภาพ อาหาร เครื่องสำอาง น้ำหอม ยาฆ่าแมลง และเนื้อผลไม้.

เรามาดูกันว่าสิ่งนี้หมายถึงอะไรในทางปฏิบัติ

1. ผลิตภัณฑ์ยาและสุขภาพ

นี่คือพื้นที่หลักของเครื่องจักร ความจำเป็นในการบรรจุยาโดสเดียวที่ปลอดเชื้อและแม่นยำในสาขาการแพทย์และสุขภาพเป็นสิ่งสำคัญยิ่ง

- ของเหลวและน้ำเชื่อมสำหรับรับประทาน: ตั้งแต่ยาแก้ไอไปจนถึงยาแก้ปวดชนิดน้ำ เครื่องนี้ให้ระบบส่งมอบที่ถูกสุขอนามัยและสะดวกสบาย

- ผลิตภัณฑ์เสริมอาหารและผลิตภัณฑ์เสริมสุขภาพ: นี่คือตลาดที่กำลังเฟื่องฟู ลองนึกถึงวิตามินชนิดน้ำ สารสกัดจากสมุนไพร คอลลาเจนช็อต และอาหารเสริมชนิดน้ำ เครื่องบรรจุที่แม่นยำของเครื่องช่วยให้มั่นใจได้ว่าแต่ละหน่วยบรรจุยาในปริมาณที่ต้องการอย่างแม่นยำ

- สารละลายในน้ำ: สารละลายทางการแพทย์ชนิดน้ำสามารถบรรจุเพื่อการใช้งานครั้งเดียวได้อย่างง่ายดาย

เทคโนโลยีนี้เหมาะอย่างยิ่งสำหรับภาคส่วนนี้ รุ่นขั้นสูงมีฟังก์ชัน "ดูดกลับ" ที่ป้องกันการหยดระหว่างกระบวนการบรรจุ ช่วยให้มั่นใจได้ว่าผลิตภัณฑ์จะไม่สูญเสีย และซีลสะอาดและแน่นหนา นอกจากนี้ การใช้ปั๊มแบบบีบรัดอิเล็กทรอนิกส์ยังทำให้ของเหลวสัมผัสกับท่อซิลิโคนแบบใช้แล้วทิ้งที่ผ่านการฆ่าเชื้อแล้วเท่านั้น จึงช่วยลดความเสี่ยงจากการปนเปื้อนข้าม

2. อุตสาหกรรมอาหารและเครื่องดื่ม

ความต้องการผลิตภัณฑ์อาหารและเครื่องดื่มแบบพกพาที่สะดวกต่อการใช้งานไม่เคยเพิ่มสูงขึ้นเท่านี้มาก่อน นี่คือจุดที่เครื่องบรรจุของเหลวอเนกประสงค์โดดเด่นอย่างแท้จริง

- เครื่องดื่ม: ความเป็นไปได้ไม่มีที่สิ้นสุด ซึ่งรวมถึงเครื่องดื่มชูกำลัง กาแฟและชาเข้มข้นแบบชงดื่ม ผงปรุงรสสำหรับน้ำดื่มแบบซอง และน้ำผลไม้สำหรับเด็ก

- ผลิตภัณฑ์จากนม: ลองนึกถึงโยเกิร์ตแบบเสิร์ฟเดี่ยว ชีสเหลว และครีมเทียมกาแฟแบบแยกส่วน โครงสร้างที่ถูกสุขอนามัยและได้มาตรฐาน GMP ช่วยให้มั่นใจได้ว่าผลิตภัณฑ์ที่ละเอียดอ่อนเหล่านี้จะได้รับการจัดการอย่างปลอดภัย

- ซอส น้ำสลัด และเครื่องปรุงรส: ความสามารถของเครื่องในการจัดการกับเนื้อครีมและผลิตภัณฑ์ที่มีความหนืดอื่นๆ ทำให้เหมาะอย่างยิ่งสำหรับซอสมะเขือเทศ มัสตาร์ด มายองเนส และน้ำสลัดแบบเสิร์ฟครั้งเดียว

- เนื้อผลไม้และน้ำซุปข้น: เหมาะอย่างยิ่งสำหรับบรรจุภัณฑ์เนื้อผลไม้ อาหารบดสำหรับเด็ก น้ำผึ้งแบบเสิร์ฟครั้งเดียว และเยลลี่ผลไม้

- ความสะดวกสบายแบบยืน: คุณสมบัติเด่นของขวดบางรุ่นคือขวดมีก้นแบน ทำให้สามารถตั้งตรงได้ด้วยตัวเอง นับเป็นข้อได้เปรียบอย่างมากสำหรับการวางจำหน่ายบนชั้นวางสินค้าในร้านค้าปลีกและความสะดวกสบายของผู้บริโภค

3. เครื่องสำอางและการดูแลส่วนบุคคล

อุตสาหกรรมความงามได้นำบรรจุภัณฑ์แบบโดสเดียวมาใช้สำหรับตัวอย่าง ผลิตภัณฑ์สำหรับเดินทาง และทรีตเมนต์ต่างๆ เครื่องบรรจุที่แม่นยำด้วยปริมาตรตั้งแต่ 0.1 มล. ไปจนถึง 200 มล. เหมาะอย่างยิ่ง

- การดูแลผิว: นี่เป็นตลาดขนาดใหญ่ เครื่องนี้สามารถบรรจุผลิตภัณฑ์แบบใช้ครั้งเดียวทิ้ง เช่น เซรั่ม มาส์กหน้า โลชั่น และครีมบำรุงรอบดวงตา ไม่เพียงแต่เหมาะสำหรับการเดินทางเท่านั้น แต่ยังช่วยรักษาประสิทธิภาพของส่วนผสมที่บอบบางอย่างวิตามินซีอีกด้วย

- การดูแลเส้นผม: ลองนึกถึงแชมพูขนาดพกพา ครีมนวดผม และน้ำมันบำรุงผมแบบใช้ครั้งเดียว หรือผลิตภัณฑ์บำรุงผมดู

- น้ำหอมและเครื่องหอม: เครื่องจักรสามารถบรรจุตัวอย่างน้ำหอมได้อย่างแม่นยำ ช่วยให้ลูกค้ามีโอกาสทดลองกลิ่นก่อนจะซื้อทั้งขวด

- การแต่งหน้า: สามารถใช้เป็นตัวอย่างรองพื้นหรือคอนซีลเลอร์สีแบบน้ำใช้ครั้งเดียวและไฮไลท์เตอร์ได้

4. สารเคมีทางการเกษตร

แม้จะดูน่าแปลกใจ แต่ความแม่นยำและความปลอดภัยของเครื่องจักรทำให้เป็นตัวเลือกที่ยอดเยี่ยมสำหรับอุตสาหกรรมการเกษตร เอกสารระบุรายการไว้อย่างชัดเจน

ยาฆ่าแมลง เป็นแอปพลิเคชั่นหลัก

การบรรจุสารเคมีที่มีฤทธิ์รุนแรง เช่น ยาฆ่าแมลงและปุ๋ยน้ำในปริมาณที่วัดไว้ล่วงหน้าและใช้ครั้งเดียว ช่วยเพิ่มความปลอดภัยได้อย่างมาก ช่วยลดการสัมผัสสารเคมีของผู้ใช้ และขจัดความเสี่ยงจากความผิดพลาดในการวัด ซึ่งอาจนำไปสู่ความเสียหายต่อพืชผลหรือการบำบัดที่ไม่มีประสิทธิภาพ ซีลที่แน่นหนาช่วยให้มั่นใจได้ว่าวัสดุอันตรายจะถูกบรรจุอย่างปลอดภัยจนถึงเวลาใช้งาน

เทคโนโลยีที่ขับเคลื่อนความหลากหลาย

อะไรที่ทำให้เครื่องจักรหนึ่งเครื่องสามารถจัดการทุกอย่างได้ ตั้งแต่น้ำหอมบางเบาไปจนถึงเนื้อผลไม้หนาๆ มันขึ้นอยู่กับคุณสมบัติทางวิศวกรรมที่สำคัญเพียงไม่กี่อย่าง

- ระบบสูบน้ำขั้นสูง: เครื่องจักรเหล่านี้ไม่ได้พึ่งพาวิธีการแบบเดียวกันทั้งหมด สามารถติดตั้งเทคโนโลยีปั๊มที่แตกต่างกันได้ ซึ่งส่วนใหญ่มักจะเป็น

ปั๊มลูกสูบอิเล็กทรอนิกส์ และ ปั๊มลูกสูบเชิงกลปั๊มแบบลูกกลิ้งเหมาะสำหรับของเหลวที่ใสและผ่านการฆ่าเชื้อ ในขณะที่ปั๊มลูกสูบที่แข็งแรงทนทานจะให้กำลังที่จำเป็นในการเคลื่อนย้ายผลิตภัณฑ์ที่มีความหนืดและข้นกว่า เช่น ยาสีฟัน ได้อย่างแม่นยำ - การควบคุมที่ซับซ้อน: เครื่องจักรสมัยใหม่ทำงานด้วยตัวควบคุมการเคลื่อนที่ความแม่นยำสูงและมอเตอร์เซอร์โวที่ควบคุมทุกขั้นตอนของกระบวนการ ซึ่งช่วยให้ผู้ปฏิบัติงานสามารถใช้อินเทอร์เฟซระหว่างมนุษย์กับเครื่องจักรที่เรียบง่าย เพื่อปรับพารามิเตอร์ต่างๆ เช่น ปริมาณการบรรจุ อุณหภูมิการปิดผนึก และความเร็วของเครื่องจักรได้อย่างแม่นยำ มั่นใจได้ถึงผลลัพธ์ที่สม่ำเสมอและมีคุณภาพสูงสำหรับผลิตภัณฑ์ทุกชนิด

- ความยืดหยุ่นของวัสดุและการออกแบบ: อุปกรณ์นี้ได้รับการออกแบบมาให้ทำงานกับฟิล์มบรรจุภัณฑ์หลากหลายชนิด ช่วยให้แบรนด์ต่างๆ สามารถเลือกวัสดุที่เหมาะสมกับความต้องการเฉพาะของผลิตภัณฑ์ได้ บางเครื่องยังมีฟีเจอร์ขั้นสูง เช่น เซ็นเซอร์โฟโตอิเล็กทริกที่สามารถจัดเรียงการพิมพ์ทั้งด้านหน้าและด้านหลังของบรรจุภัณฑ์ เพื่อสร้างรูปลักษณ์ที่เรียบหรูและเป็นมืออาชีพ

มากกว่าแค่ชื่อ

ชัดเจนว่า "เครื่องบรรจุของเหลวในช่องปาก" เติบโตเกินชื่อ เป็นโซลูชันสากลสำหรับทุกอุตสาหกรรมที่สามารถใช้ประโยชน์จากบรรจุภัณฑ์แบบโดสเดียวที่สะอาด สะดวก และแม่นยำ ความสามารถในการจัดการผลิตภัณฑ์ได้อย่างปลอดภัยหลากหลายประเภท ตั้งแต่ยาและอาหาร เครื่องสำอาง และสารเคมี ทำให้เป็นหนึ่งในอุปกรณ์บรรจุภัณฑ์ที่มีความยืดหยุ่นและมีมูลค่าสูงสุดในตลาดปัจจุบัน ด้วยการผสานการขึ้นรูป การบรรจุ และการปิดผนึกเข้าเป็นหน่วยเดียวที่มีประสิทธิภาพและกะทัดรัด จึงนำเสนอโซลูชันที่ทันสมัยเพื่อตอบสนองความต้องการที่เพิ่มขึ้นอย่างต่อเนื่องสำหรับการบรรจุแบบโดสเดียว