Top 10 European Semi-Automatic Capsule Filling Machine Manufacturers

What Size Pills Can a Pill Press Make? Understanding Pill Size, Tooling & the GZPK-26

Is a Sugar Coating Machine Really the Best Choice?

What are the Disadvantages of Sugar Coating?

Tablet coating is a crucial step in pharmaceutical manufacturing. It protects active ingredients, masks unpleasant tastes, and makes tablets easier to swallow. For decades, sugar coating was the gold standard. It gave tablets a smooth, shiny, and easily recognizable appearance. But is this traditional method still viable today?

The answer is increasingly clear: no.

While sugar coating has its appeal, modern pharmaceutical science has revealed its significant shortcomings. The process is inefficient, inconsistent, and can lead to quality issues in the final product. In this blog post, Bruce Fu, an expert in pharmaceutical machinery from Grand Machinery, will briefly explore the often-overlooked drawbacks of sugar coating and explain why many manufacturers are turning to more advanced methods.

1. Time-Consuming and Labor-Intensive Process

The most significant drawback of sugar coating is its complexity and lengthiness. It's not a one-step process; it involves several distinct stages. Each stage adds to the production cycle time and labor requirements.

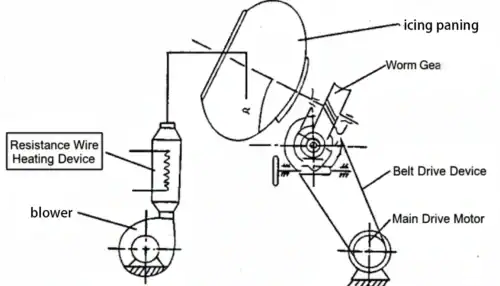

Consider a classic sugar coating machine like the BY-400. The process begins with sealing the tablet core to prevent moisture absorption. Next comes the undercoating stage, which shapes the tablet. Then, there are the smoothing and coloring stages, layering coatings to achieve a uniform thickness. Finally, the tablets are polished for that classic shine.

This contrasts sharply with modern film coating processes, which can be completed in a fraction of the time. According to a review article by Cole et al. in the Journal of Pharmaceutical Technology, the entire sugar coating process can take 4 to 6 hours, sometimes even longer, depending on the desired thickness and color. This makes it a bottleneck for high-volume production lines.

The process often requires manual intervention. As the BY-400 manual states, operators must "manually operate" the process to apply the syrup and ensure even distribution. This reliance on human skill introduces variability and slows down the entire operation, making it difficult to scale up.

2. Inconsistent and Unpredictable Results

Achieving a uniform, high-quality sugar coating is more of an art than a science. The outcome is highly dependent on environmental factors and operator skill.

Variables such as temperature, humidity, and the viscosity of the syrup mixture all affect the final product. Even slight variations can lead to defects. For example, if the drying process is too slow, the sugar coating surface can become rough and pitted. The BY-400 manual even mentions that the machine needs to “ensure optimal process parameters” to prevent “pitting.” This highlights the difficulty of controlling the outcome, even with the right equipment.

Modern alternatives, such as automated film-coating systems, offer greater precision. They use sophisticated controls to regulate spray rate, airflow, and temperature. This ensures a consistent, uniform coating on every tablet—something that traditional sugar coating struggles to achieve.

3. Patient-Centric Drawbacks

The drawbacks of sugar coating don't just affect the production process. They impact the end user—the patient.

4. Increased Size and Weight

One of the most obvious problems is the excessive thickness of the sugar coating. Sugar-coated tablets can weigh 50% to 100% more. This significant weight increase makes tablets difficult to swallow, especially for children or the elderly.

Furthermore, a thicker coating means a larger tablet. This can affect drug absorption and lead to a poor patient experience. A study by Lachman et al. in the Journal of Pharmaceutical Sciences emphasizes this point, stating that the substantial weight increase of sugar-coated tablets is a major drawback compared to film-coated tablets, which only add a negligible amount of weight.

Sweet Problem: Dietary and Health Concerns

Using sucrose as the primary coating ingredient raises dietary concerns. Many patients have diabetes or are on a restricted-calorie diet. For them, taking multiple sugar-coated tablets daily adds considerable sugar intake, potentially impacting their health management. Film-coated tablets, typically sugar-free, avoid this issue.

Susceptibility to Cracking and Damage

While sugar-coated tablets appear smooth and durable, they are actually quite fragile. They can crack, chip, or break during packaging, transport, or storage. This not only makes the tablets look unprofessional but also exposes the core to the environment, potentially compromising its stability and efficacy.

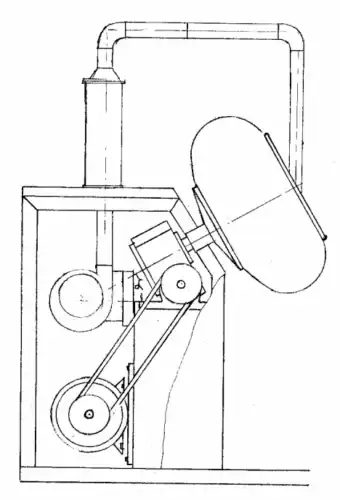

The BY-400 Model: A Look Back

Understanding the specifications of a typical traditional sugar coating machine, like the BY-400, explains why these problems are so prevalent.

Production Capacity: The BY-400 has a relatively small production capacity.

It can process 1-6 kg of tablets per batch. This is suitable for small-scale production or laboratory use, but cannot meet the needs of large-scale production in the modern pharmaceutical industry.

Simple design: The device uses a simple electric fan for heating. This simple design lacks the precision necessary for temperature and airflow control, making it challenging to ensure consistent product quality. This is an inherent limitation that modern equipment has overcome.

Manual operation: The BY-400 requires manual operation. This means human errors are unavoidable, a significant drawback for the pharmaceutical industry, which prioritizes product quality.

For companies looking to scale up production, larger tablet coating machines or similar automated equipment are needed. However, even these larger machines cannot fully overcome the inherent challenges of the coating process itself; therefore, film coating technology has become the preferred process for most large pharmaceutical companies.

Comparison of Tablet Coating and Film Coating:

Ultimately, the choice between tablet coating and film coating depends on whether you prioritize tradition or efficiency.

Speed: Film coating is fast, completing in minutes. Tablet coating takes several hours.

Control: Film coating enables precise control over coating thickness and uniformity, and is fully automated. Tablet coating relies heavily on manual operation and environmental factors.

Patient experience: Film coating adds minimal weight and volume to the tablet, making it easier to swallow. Furthermore, film-coated tablets are sugar-free, offering significant health benefits for many patients.

Cost: While simple tablet coating machines like the BY-400 have lower initial costs, the labor, energy, and material costs of the tablet coating process itself are high, resulting in significantly higher overall costs than film coating in the long run.

In conclusion

While tablet coating has a long history and aesthetically pleasing results, its numerous drawbacks cannot be ignored in the rapidly evolving pharmaceutical industry. The pharmaceutical industry's shift towards film coating reflects the pursuit of efficiency, precision, and patient well-being.

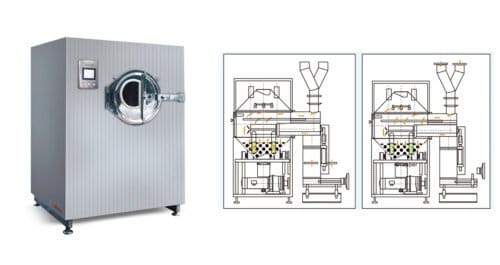

At this point, Bruce Fu, an expert and CEO from Grand Machinery with many years of experience, pointed out: "We recommend our company's tablet coating unit, which also performs film coating. It has an automated system and can better meet the needs of medium and large pharmaceutical companies and health product companies. Small sugar coating machines are still suitable for small companies and are used on a small scale." Welcome to contact us for questions about coating machines

References

Cole, G., Ghebre-Sellassie, I., & Tovey, J. (2000). Tablet Coating: Film Coating Technology. Pharmaceutical Technology, 24(9), 108-112.

Lachman, L., Lieberman, H. A., & Kanig, J. L. (1976). The Theory and Practice of Industrial Pharmacy. Lea & Febiger.

Porter, S. C. (2002). Film Coating as an Alternative to Sugar Coating. In Ghebre-Sellassie, I. (Ed.), Pharmaceutical Dosage Forms: Tablets (Vol. 3, pp. 117-142). Marcel Dekker.

Film Coating vs. Sugar Coating with Today’s Coating Machine. grandpackmachine.com.

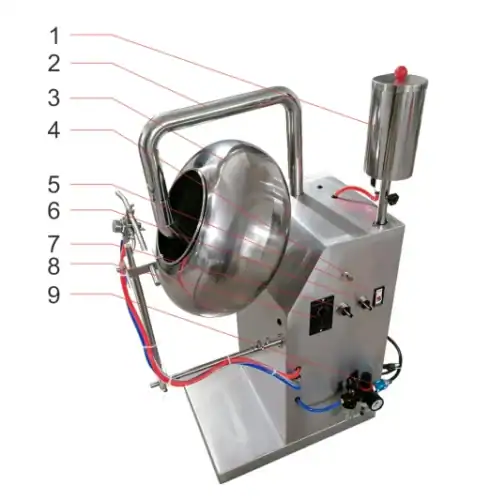

1. Machine Appearance

| Description | Used for coating and polishing formed tablets (pharmaceutical) as well as candy and coated products in the food industry. |

|---|

2. Machine Application

| Main Application |

To uniformly coat and polish tablets; also applicable for food coating such as candy pills. Coating produces a glossy surface, protects tablets from oxidation, moisture, and volatilization, masks unpleasant taste, makes them easier to identify, and aids dissolution in the stomach. |

|---|

III. Basic Technical Parameters

| Parameter | Value |

|---|---|

| Coating Pan Diameter | 400 mm |

| Production Capacity | 1–6 kg / batch |

| Heating Wire Power | 500 W |

| Coating Pan Speed | 46 rpm |

| Main Motor Power & Model | 120 W |

| Blower Motor Power & Model | 60 W |

| Blower Air Volume | 100 m³/min |

| Floor Space | 400 × 630 mm |

| Hot Air Outlet Temperature | 50 °C |

| Weight | 35 kg |

| Height | 850 mm |

IV. Structural Introduction

| No. | Component |

|---|---|

| 1 | Air Supply Switch |

| 2 | Internal Heating Duct |

| 3 | Coating Pan Body |

| 4 | Compressor Interface |

| 5 | Main Power Switch |

| 7 | Internal Heating Switch |

| 8 | Motor Speed Controller |

V. Operating Principle & Structural Features

| Operating Principle |

Sugar syrup is manually sprayed onto the tablets and mixed with a mixing element. The clockwise rotation of the coating pan makes the tablets tumble, slide, and grind, ensuring even distribution of the syrup. Hot air is simultaneously introduced to remove moisture, leading to crystallization and polishing, resulting in qualified sugar-coated tablets. The machine ensures a stable linear speed and an ideal tablet flow profile, meeting requirements of uniform coating, bright color, and no pitting. |

|---|---|

| Structural Features |

|

VI. Lubrication

| No. | Lubricant | Lubricating Part |

|---|---|---|

| 1 | HJ-10 | Reducer oil sump |

| 2 | ZG-2 | Rolling bearing |

| 3 | ZG-2 | Rolling bearing |

VII. Maintenance & Safety

| Item | Details |

|---|---|

| Lubrication | Replace gearbox oil and bearing grease regularly. |

| Long-term storage | Clean and oil the coating pan to prevent oxidation and toxic copper compound formation. |

| Operating temperature | Temperature rise of gearbox housing must not exceed 50 °C during operation. |

| Seal check | Inspect and replace oil seal at worm shaft end regularly (generally every 6 months). |

| Grounding | Machine must be reliably grounded; ground resistance ≤ 4 Ω. |

| Safety guards | Do not remove electrical or belt guards at will. |

Note: Information summarized based on BY-400 model specifications.