Grand Fluid Bed Dryer for Importers and Procurement Teams

The Ultimate Guide to Emulsifier Machines

Which Granulator is Used in Wet Granulation?

Wet granulation is a core process in tablet manufacturing, where dry powders are agglomerated by spraying a binder liquid while mixing.

As researchers Morin and Briens note, in wet granulation “a liquid binder is sprayed onto the particles as they are agitated, usually in a high-shear mixer or fluidized bed”1. In practice, high-shear mixers (also called rapid mixer granulators) and fluid-bed granulators are the most common equipment for this purpose. In fact, a recent industry publication observes that “high-shear wet granulation… [has] been successfully used by the pharmaceutical industry for decades”2. Below we review how these machines work and when each is used.

Wet granulation-Inner wall of pot - 316L material

High-Shear (Rapid Mixer) Granulators

A high-shear granulator (often called a rapid mixer granulator or wet mixing granulator) is the classic machine for batch wet granulation. It consists of a closed mixing bowl with a high-speed impeller and a chopper blade. In operation, powder ingredients and binder are placed in the bowl and the impeller rapidly spins, kneading the powder into wet agglomerates. An industry description explains: “The dry powders are mixed by the rotating impeller before a liquid binder is added. The impeller produces high-density granules… The chopper prevents excessive granule growth and distributes the granulation fluid throughout the product.”2

In other words, the impeller creates intense shearing and compaction, while the chopper cuts large lumps, yielding uniform granules. One equipment maker notes that its high-shear mixer produces “medium to high density granules with excellent flow and compression characteristics”4. Because of its vigorous mixing, a high-shear granulator is very effective at wet mixing and producing dense granules. It is suitable for many formulations and batch sizes (from lab to production scale). The impeller/chopper design speeds granule formation and ensures a homogeneous mass. For example, the Grand® high-shear system is explicitly “designed for efficient and homogeneous wet granulation of powders” to form flowable, compactable granules. (Rapid mixer granulators are sometimes called wet granulators or high-shear mixers in pharma machinery catalogs3.)

After processing, the wet granules are typically transferred to a fluid-bed dryer to remove moisture. High-shear systems come in different styles (e.g. top-drive vs. bottom-drive) and sizes, but the basic mixing principle is the same. In summary, for wet granulation the rapid mixer granulator is the workhorse machine: it quickly mixes binder into the powder under high shear, creating uniform wet granules ready for drying2.

Wet Granulator Series from Grand

Fluid-Bed Granulators

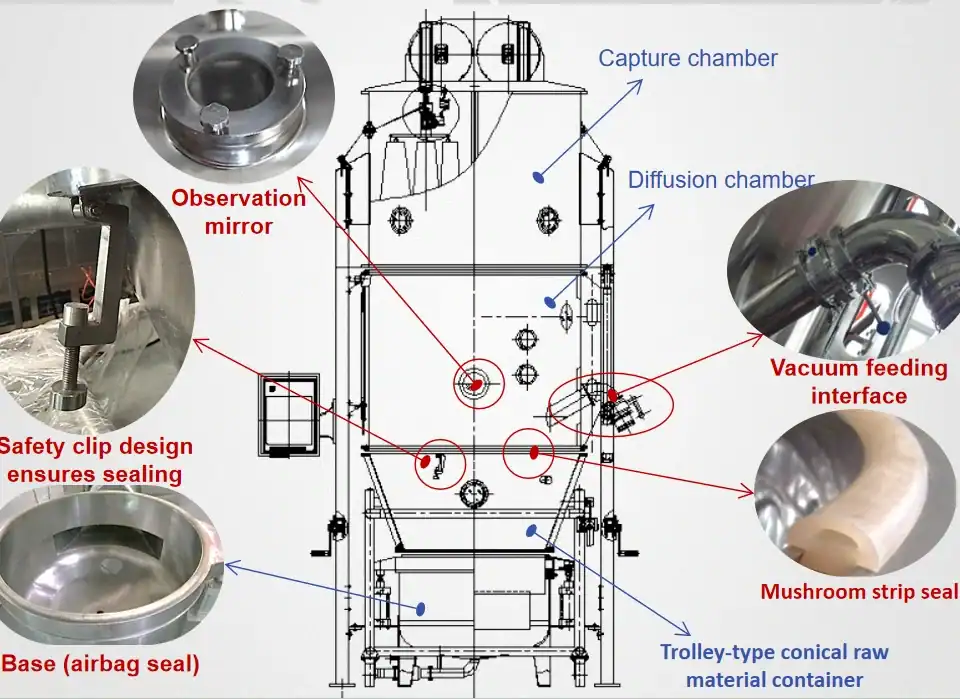

Another widely used wet granulation method employs fluid-bed granulators. In a fluid-bed system, powder is suspended (“fluidized”) on a strong upward airflow. Granulation liquid (water or solvent with binder) is sprayed onto the fluidized powder bed from one or more nozzles. The binder droplets cause particles to agglomerate as they collide in the air. An AbbVie technical article describes fluid-bed equipment as a “specialized, multi-purpose piece of equipment [capable] of mixing, granulating, and drying” in one vessel5.

In other words, the same fluid-bed machine keeps the powder airborne, sprays on binder, and dries the wetted granules with heated air. In practice, a fluid-bed granulator can therefore complete mixing and drying in a single step. For example, the air stream both agitates the powder and removes moisture, so once the desired granule size is reached, drying continues until end-point. Review literature highlights that a fluidized-bed granulator is “a highly economical and efficient one pot process” for converting powders into granules6.

The continuous airflow provides excellent heat and mass transfer, making drying very uniform. AbbVie notes that fluid-bed granulation is “the most popular technique, owing to its high reproducibility and scalability” for large-scale production5. The trade-off is that fluid-bed systems impart no mechanical kneading (no impeller or chopper), so mixing is less aggressive. This can be fine for many formulations, but very high-shear binder incorporation is better in an RMG. Nonetheless, fluid-bed granulators are ideal when throughput and integration are important: one machine handles mixing, granulation, and drying together.

They are especially favored for formulations needing gentle mixing or high thermal mass (the hot air thoroughly dries granules immediately). Advantages of fluid-bed granulators: Air suspension provides efficient granule drying and uniform mixing of the binder, often in a single unit5. For example, one source lists fast wetting, agglomeration, and drying as benefits of fluid beds. They also tend to produce relatively porous, free-flowing granules. (Disadvantage: Powder can segregate or stick if not fluidized well, but modern designs (top-spray, Wurster, tangential spray) mitigate these issues.)*

Wet Granulator-Siemens operation screen

Other Wet Granulation Equipment

Besides high-shear and fluid-bed systems, several other mixers can perform wet granulation. Smaller-batch or lab scales may use planetary (Henschel) mixers or double-cone mixers with binder spray.

These tumbling mixers have multiple impellers and can handle sticky masses. Another common method is single-pot (tray) granulation, where powder is mixed in a vessel and binder added without high shear.

Finally, continuous twin-screw granulators (TSGs) can perform wet granulation by forcing powder and binder through intermeshing screws; these are growing in use for continuous manufacturing. In summary, pharmaceutical wet granulation typically uses high-shear mixer granulators or fluidized-bed granulators, though planetary mixers or twin-screw machines are alternatives in certain scenarios25.

Grand Fluid Bed Dryer for Importers and Procurement

Choosing the Right Wet Granulator

For equipment buyers, the choice of wet granulator depends on process needs. High-shear granulators (rapid mixers) are often chosen for their intense mixing power and control over granule density, making them well-suited to medium-to-large batch sizes and sticky formulations. Fluidized-bed granulators, by contrast, are attractive when drying efficiency and scalability are priorities: they are noted for reproducible results and can handle higher throughput5.

Key considerations include batch volume, desired granule properties, moisture content, and cleaning requirements. Both types are considered pharmaceutical machinery and must meet GMP design.

In many modern plants, a hybrid approach is used: for example, a high-shear RMG followed by transfer to a fluid-bed dryer4. In any case, understanding the mixing and granulating action of each machine ensures the right choice for wet granulation.

References:

Morin G., Briens L. AAPS PharmSciTech 15(4):1039–1048 (2014). "A comparison of granules produced by high-shear and fluidized-bed granulation methods." DOI:10.1208/s12249-014-0134-7.

Borgers T. Scientist Live (2021). "The essentials of wet granulation." Dec 10, 2021.

UPMACH. "Rapid Mixer Granulator (High Shear Mixer Granulator)." UPMACH Solid Machines.

Granulators in the Pharmaceutical Industry – A Comprehensive Overview.-Grand Pack

AbbVie Contract Manufacturing. "Fluid Bed and Melt Granulation in Pharmaceutical Manufacturing." AbbVie News & Insights. (2020).

Int. J. Pharm. Sci. Rev. Res. 6(4):133-140 (2020). "Fluidized Bed Granulation: A Promising Technique." globalresearchonline.net.