¿Qué tan adaptable es la máquina estuchadora?

¿Cómo se consigue el sellado de la ampolla?

Introducción

For a long time, glass bottles have dominated the packaging of medicines, including ampules, vials, glucose bottles, and reagent tubes. Ampoules are elegantly designed and stand out from the crowd. So, how are these widely used ampoules made?

The answer lies in ampoule filling and sealing machines. For example, the production line below integrates both ampoule filling and sealing functions.

This integrated production line consists of a QCLX series vertical ultrasonic bottle washer, an SGZ series tunnel-type hot air circulation sterilization oven, and an AGF series vertical ampoule filling and sealing machine.

With its simple and aesthetically pleasing design, compact footprint, and easy cleaning, it is suitable for filling and sealing small-volume injection ampoules (1-20ml).

It seamlessly integrates the manufacturing process steps of ampoules, including water spraying, ultrasonic cleaning, flushing, aeration, drying and sterilization, cooling, filling, and sealing.

With its advanced design, rational structure, and stable performance, it provides technical support for aseptic production of pharmaceuticals and complies with the requirements of current Chinese Good Manufacturing Practice (GMP).

I've been watching some Netflix shows recently. When injecting medication, agents, or doctors always pull out bottles like ampoules and syringes to draw the medicine for injection.For example, what are the different types of ampoules?

These are primarily glass and plastic ampoules.

Glass Ampoules

The National Medical Products Administration mandates the use of curved-neck snap ampoules. These ampoules are easy to use and prevent contamination of the drug solution by glass shards and particles after breaking. There are two types of curved-neck snap ampoules: color-ring snap ampoules and dot-score snap ampoules.

1. Color-Ring Curved-Neck Snap Ampoules

Color-Ring Curved-Neck Snap Ampoules are made by melting a low-melting-point powder with an expansion coefficient twice that of the ampoule glass into the ampoule neck, forming a ring.

Upon cooling, the different expansion coefficients of the two glasses create a permanent stress around the ring, allowing it to break smoothly with a simple bend, without generating glass shatters.

2. Point-Score Curved Neck Breakaway Ampoules

Point-score breakaway ampoules feature a fine score on the curved neck, with a 2mm diameter colored dot at the center. To break, apply force to the back of the bottle, just in the middle of the score. The broken surface should be smooth.

Plastic Ampoules

Plastic ampoules are manufactured using a three-in-one blow-fill-seal (BFS) process. Blowing, filling, and sealing are all performed in a single station. Combined with aseptic production conditions, this significantly reduces microbial contamination and improves sterility assurance.

Due to the plastic's excellent ductility, plastic ampoules can be manufactured in a variety of shapes and sizes, offering a wider range of filling volumes than glass ampoules. In addition to the aforementioned advantages, plastic ampoules also offer the following features:

① Due to the material's high ductility, they are free of debris。

② They utilize a twist-action opening mechanism for easy operation.

③ The broken edge is not sharp, preventing injuries to caregivers。

④ They feature color-printed labels for easy identification and prevent medication errors;

⑤ The material is durable and impact-resistant, making it easy to transport and carry.

The following table summarizes a comparison of ampoules.

| Category | Glass Ampoule | Plastic Ampoule | |

|---|---|---|---|

| Polyethylene Ampoule | Polypropylene Ampoule | ||

| Main Material | Silicon dioxide, Boron oxide, Aluminum oxide | Polietileno | Polypropylene |

| Light Transmittance | Transparent, smooth, easy to clean | Poor light transmittance | Poor light transmittance |

| Physical & Chemical Properties | Withstands 121°C high-temperature sterilization | Generally does not withstand sterilization temperatures above 110°C | Withstands 121°C high-temperature sterilization |

| Applicability | Good sealability, suitable for easily oxidized drugs | Good sealability, but not suitable for easily oxidized drugs due to gas permeability | Good sealability, but not suitable for easily oxidized drugs due to gas permeability |

| Clinical Use | Prone to generating glass debris and causing cuts when opened | Safer to open | Safer to open |

| Storage & Transportation | Fragile, heavy, inconvenient for transportation and storage | Not fragile, lightweight, easy to transport and store | Not fragile, lightweight, easy to transport and store |

The Science of Modern Ampoule Sealing

In the pharmaceutical world, the integrity of injectable drugs is paramount. Even the slightest exposure to contaminants can render a life-saving medication ineffective or dangerous. This is why the humble glass ampoule remains a cornerstone of sterile packaging. But have you ever wondered how these small glass vials are filled and sealed so perfectly, creating an impenetrable barrier against the outside world?

The answer lies in a highly precise and automated process, perfected by modern machinery like the Grand Ampoule Filling and Sealing Machine. This process revolves around two critical keywords: llenado de ampollas and, most importantly, Ampoule sealing. Let's break down how this fascinating technology works.

Precision Ampoule Filling

Before sealing can occur, the ampoule must be filled with absolute precision. An incorrect dose is not an option in medicine. The process begins with sterilized, empty ampoules being automatically fed into the Grand machine's conveyor system.

To protect sensitive drug formulations from oxidation, a crucial step of pre-gassing often takes place. The machine flushes the ampoule with an inert gas, typically nitrogen, to displace oxygen. Immediately following this, the llenado de ampollas stage begins.

The Grand machine utilizes high-precision pumps to dispense the exact, pre-determined volume of liquid product into each ampoule. This automated dosing ensures consistency, accuracy, and adherence to strict pharmaceutical standards, batch after batch. Another flush of nitrogen may follow to ensure the headspace above the liquid is also free of oxygen.

The Flame-Kissed Art of Ampoule Sealing

With the ampoule correctly filled, it moves to the most critical and visually impressive stage: Ampoule sealing. The goal is not simply to close the container, but to fuse the glass back into a single, seamless piece, creating a true hermetic seal.

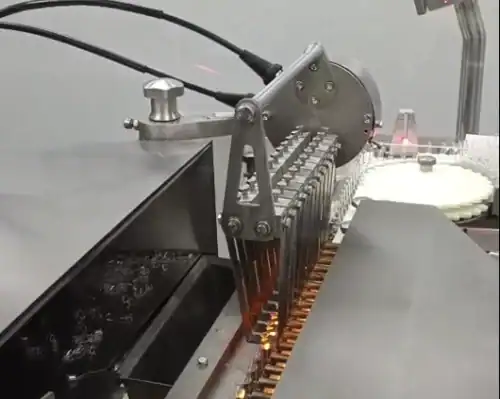

This is achieved through a method known as flame sealing. The Grand Ampoule Filling and Sealing Machine is equipped with a set of specialized burners that generate intense, precisely controlled flames. As the filled ampoule is rotated, these flames are directed at the narrow part of its neck. The concentrated heat quickly brings the glass to a molten state.

Once the glass is malleable, a set of grippers gently pulls the top of the ampoule upwards while it continues to rotate. This action stretches the molten glass, narrowing it into a fine point before it separates and cools. The result is a perfectly rounded, sealed glass tip, completely isolated from the external environment. This “pull-sealing” technique ensures a thick, durable seal free from the risks of micro-fissures or imperfections.

Why Automation is Non-Negotiable

While the concept of melting glass is simple, achieving a perfect seal every time requires automation. The Grand Ampoule Filling and Sealing Machine ensures that every variable is controlled:

Consistent Heat: The flame temperature and duration are identical for every ampoule, preventing overheating or incomplete seals.

Esterilidad: The automated process minimizes human intervention, which is essential for maintaining an aseptic environment.

Speed and Efficiency: The integrated system seamlessly handles everything from loading and filling to the final Ampoule sealing, delivering high throughput for large-scale production.

In conclusion, the process of llenado de ampollas and sealing is a remarkable blend of science and engineering. It is this precise, automated thermal process, perfected by machines like those from Grand, that allows us to trust the purity and safety of the sterile medications we depend on.