Liquid Capsule Filling Machine NYF-600

Using the NYF-600 liquid capsule filling machine, you can easily fill capsules with the liquid of your choice right in your own home or business.

Features

The NYF-600 is equipped with a number of features and accessories that speed up and facilitate the process of filling capsules. First, it has the vacuum positioning mechanism, which rapidly loads the hopper with empty caps and sets it to the automatic loading point. Then, the optical sensor that separates the caps from the bodies of the capsules that have been automatically placed on the loading spot.

Filled capsules are transported by guide chutes in orderly way to the sealing machine. There are three basic process to seal the capsules, including creating a thin layer of glue on soap with rubber wheel, and heating up the container by a long conveyer system, to ensure the quality of the capsules sealed.

Features

How it works

The filling process starts by loading empty capsules into the hopper. They pass through the vacuum positioner to be separated into bodies and caps. The bodies are automatically filled with the liquid of your choice, dosed precisely.

The filled bodies are dispensed to a capping machine where caps are placed on top, the cap edge is glued and then the conveyer provides the curing time needed for a good seal.

Specifications

| Machine weight: | 1500kg |

| Dimensions: | 3565×1100×2100mm |

| Motor Power: | 7.75kw |

| Power Supply: | 380V;50Hz |

| Dimensions: | 4100x1300x2150mm |

| Production Capacity: | 600 capsules/minute |

| Capsule Size: | 00#~2# and safety capsules A~E |

| Capsule loading rate: | ≥99.5% |

| Noise: | ≤75dBA |

| Control system: | PLC control |

| Material: | 304 and 316L stainless steel |

| Compressed Air: | 0.06m3/min 0.3Mpa |

| Vacuum: | -0.02~-0.06 MPa |

| Water flow: | 250L/h |

| Inlet pipe: | 20mm |

| Drain pipe: | 27mm |

| Working Environment Temperature: | 21℃±3℃ |

| Mold Holes: | 16 Holes |

| Plant height requirements:: | Manual feeding ≥2.6m, vacuum feeding ≥2.8m |

| Humidity requirements: | 40~55% |

| Exhaust Volume: | 300m3/h |

Machine Details

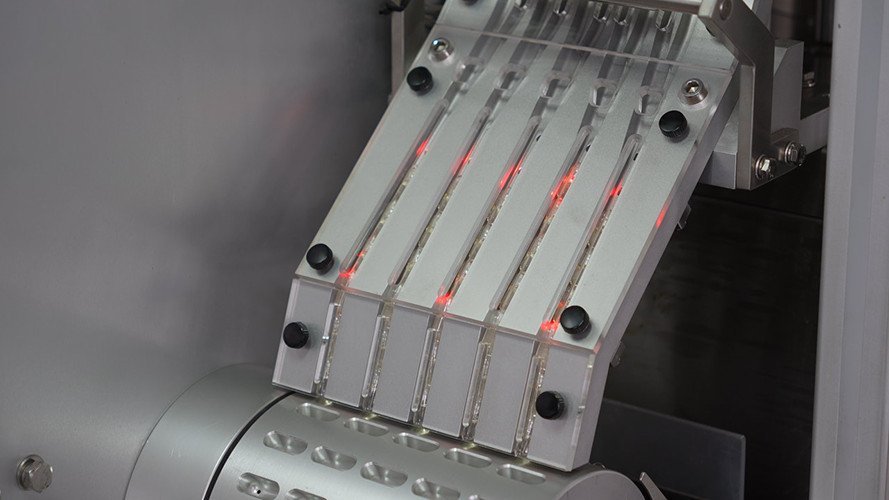

Liquid capsule filling plate

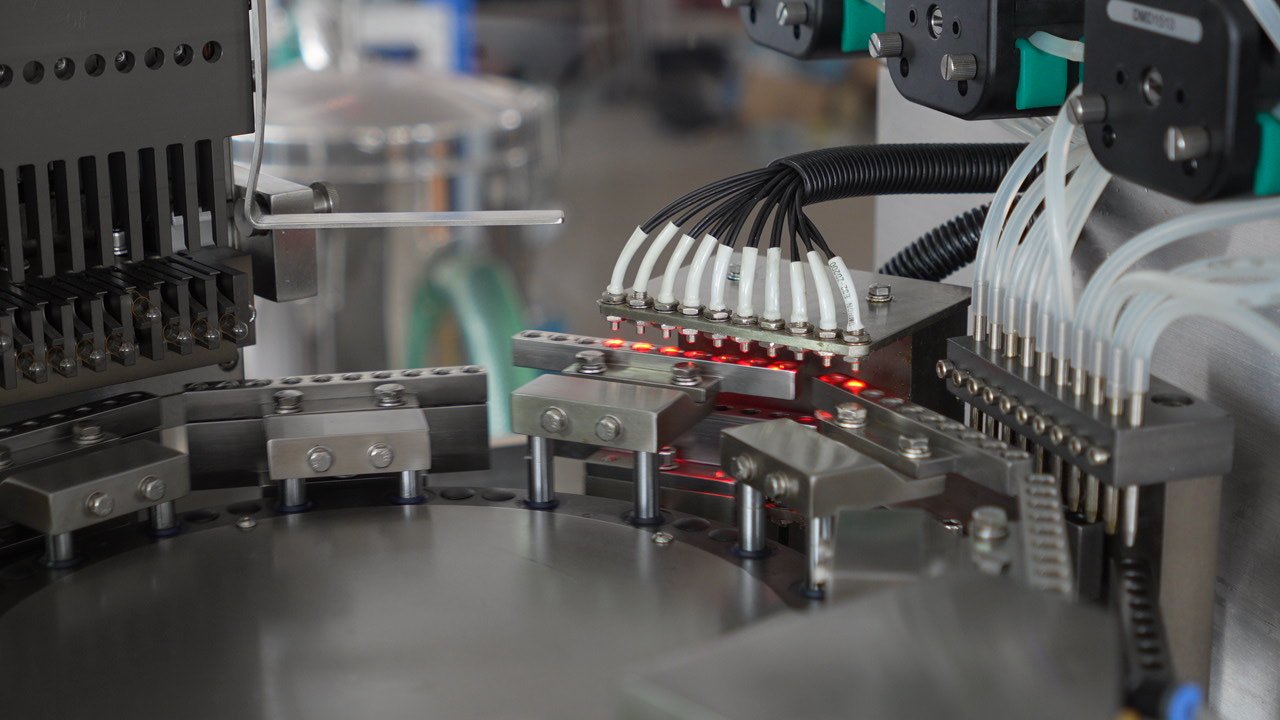

Liquid Doser

Peristaltic Pumps

Filling head

Capsule Roller

PLC Control

Capsule Filling Plate

Cutting Board

Capsule conveyor belt

Capsule filling belt

Liquid storage tank

Workbench

Contact Us

Scientists Develop Latest Liquid Capsules