Fish Oil Supplements: A Scientific Guide to Intake and the Secrets of Soft Gel Capsule Making Machine

Grandpack: Revolutionizing Pharmaceutical Packaging Solutions

Tube Filling Machine: 5 Things You Must Know

Introduction

Tube Filling Machine is at the heart of modern packaging. It transforms the way products like toothpaste, lotions, and adhesives are packaged. If you have ever wondered how creams or liquids get into tubes, this article is for you. We will cover five key points that every manufacturer and industry enthusiast should know.

What is a Filling Machine?

A tube filling machine fills tubes with liquids, gels, pastes, or creams. It is used for products such as hand lotions, shampoos, paints, and even cake icings. In the past, workers manually filled tubes with spoons or squeezes. That method was slow and messy. Today, automation has transformed the process.

Automated tube filling increases speed and precision. Every tube receives the correct amount of product. Data shows that fully automated machines can fill thousands of tubes per hour. This level of accuracy minimizes waste and ensures top quality. Manufacturers rely on tube filling machines to boost efficiency and maintain high hygiene standards in production.

How Does a Tube Filling Machine Work?

A tube filling machine operates in a series of automated steps. Here is a clear breakdown:

- Feeding:Empty tubes are fed into the machine, either manually or automatically.

- Orientation:The machine positions each tube with its open end facing upward.

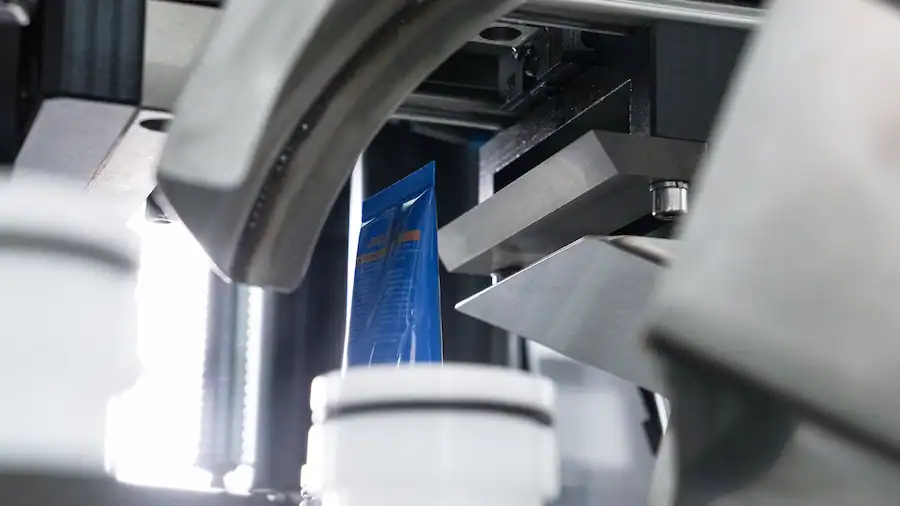

- Filling:Depending on the product’s viscosity, a suitable filling system is used. Pumps like piston or syringe types deliver the ideal amount of liquid, gel, or paste.

- Sealing:After filling, the machine seals the tube using heat, ultrasonic waves, or pressure. This prevents leaks and spills.

- Post-Processing:Sealed tubes are then moved for additional steps, such as capping, labeling, or boxing.

Each step is controlled by advanced sensors and controllers. The system continuously checks for accuracy. The result is a uniform, high-quality fill every time. No more messy, hand-filled tubes—every tube is perfect.

Types of Tube Filling Machines and How to Choose One

There are several types of tube filling machines. Your choice depends on your production needs, product variety, and budget. Here are the main types:

Semi-Automatic Tube Filling Machines

- Features:Compact and user-friendly design.

- Production Capacity:Typically fills hundreds of tubes per hour.

- Use Cases:Ideal for startups, lab tests, or small-scale production.

- Operation:Some processes are automated, while others require manual handling.

Semi-automatic machines are cost-effective and great for trial runs. They balance automation with necessary manual control.

Fully Automatic Tube Filling Machines

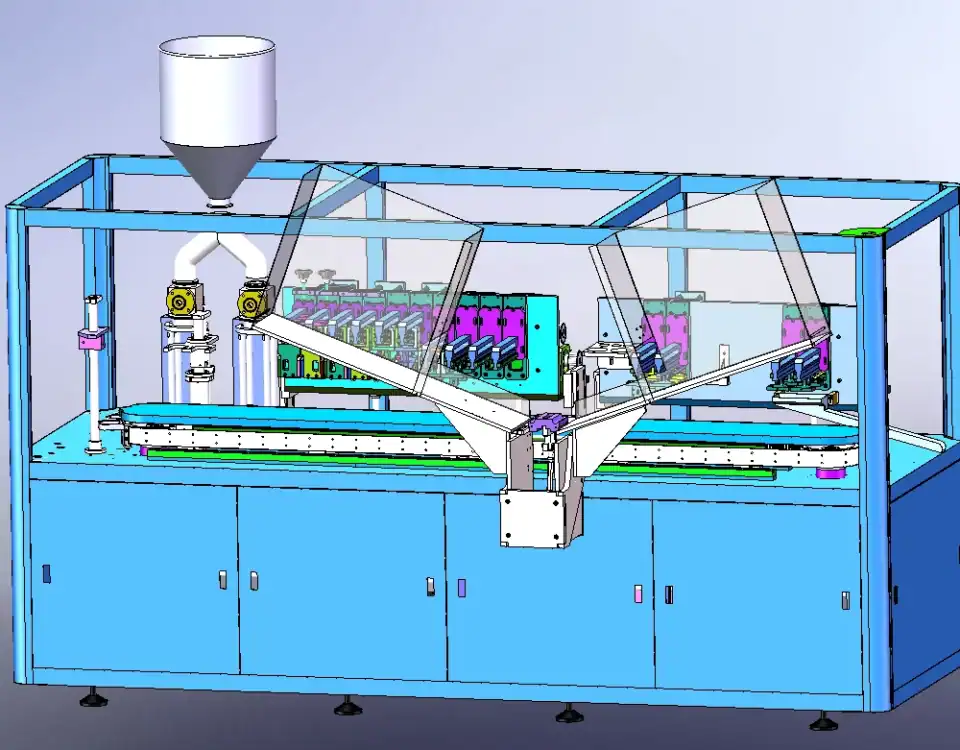

- Features:Fully automated with PLC and servo motor controls.

- Production Capacity:Can fill thousands of tubes per hour.

- Use Cases:Best suited for large-scale production in pharmaceuticals, cosmetics, and food industries.

- Advantages:Lower labor costs, high speed, and consistent accuracy. Minimal human intervention is needed.

Fully automatic machines are built for mass production. They include advanced features like weight checking and leak detection. These systems ensure each tube is filled and sealed to perfection.

Rotary Tube Filling Machines

- Features:High-speed rotary table design with robotic pick-and-place systems.

- Production Capacity:Capable of filling up to 40,000 tubes per hour.

- Use Cases:Perfect for heavy-duty production environments, especially in pharmaceutical and cosmetic manufacturing.

- Advantages:Compact footprint, rapid changeovers for different tube sizes, and high precision via advanced servo controls.

Rotary tube filling machines are designed for maximum output. They are ideal for companies that need to maintain high production volumes without sacrificing quality.

When selecting a tube filling machine, consider your production volume, labor costs, investment budget, and product diversity. A semi-automatic machine is suitable for smaller runs, while fully automatic or rotary models are best for large-scale operations. Making the right choice will significantly boost your production efficiency and product quality.

Technical Advantages and Future Trends

Tube filling machines offer many technical benefits. They improve production efficiency, reduce labor costs, and ensure high product quality. Here are some key advantages and trends:

Production Efficiency and Accuracy

- Speed:Automated systems can fill thousands of tubes per hour.

- Precision:Servo controls and laser sensors ensure accurate fill levels.

- Consistency:Every tube is filled uniformly, reducing product waste and maintaining quality control.

Reduced Labor Costs

- Automation:Minimal human intervention lowers labor expenses.

- Intelligent Detection:Built-in sensors detect issues early, alerting operators immediately.

- Cost Savings:Fewer errors and less manual handling reduce overall production costs.

Versatility and Multi-Functionality

- Material Flexibility:These machines work with plastic, metal, and composite tubes.

- Wide Product Range:They are suitable for everything from thin liquids to thick pastes.

- Additional Operations:Many models integrate capping, labeling, and packaging functions in one system.

Future Trends in Tube Filling Technology

- Industry 4.0 Integration:IoT, data analytics, and machine learning will drive future innovations. Expect self-diagnosis and predictive maintenance features.

- Smart Maintenance:Automated monitoring will reduce downtime and ensure optimal performance.

- Eco-Friendly Packaging:As sustainability grows in importance, machines will adapt to handle recyclable and biodegradable materials.

- Advanced Robotics:Further automation in loading and unloading will enhance speed and precision.

- Customization:Flexible designs and quick changeovers will support mass customization for diverse product lines.

Market reports predict steady growth in the tube filling machine industry. With the rise of e-commerce and direct-to-consumer brands, the demand for efficient, full-sealing packaging solutions is increasing. Manufacturers are continually innovating, and tube filling machines are becoming smarter, more efficient, and eco-friendly.

Maintenance and Upkeep of Tube Filling Machines

Regular maintenance is crucial to ensure that your tube filling machine operates efficiently. Here are seven essential maintenance tips:

1. Machine Placement

- Place the machine in a safe, clean, and well-ventilated area.

- Maintain a room temperature between 18–26°C and humidity between 45–65%.

- Ensure the floor is level and non-slip.

- Position the machine at least 1.8 meters away from walls. This guarantees proper ventilation and easy access.

- Follow the manufacturer’s guidelines regarding machine dimensions and adjustable support points.

2. Power Supply

- Use a 220V 50Hz AC power supply (three-phase, four-wire system).

- Securely connect the power cable to the designated terminal.

- Regularly inspect the power module to avoid fluctuations that could damage the machine.

3. Air Supply

- Ensure a clean air supply with a pressure below 8kg/cm² and an airflow above 1.1m³/min.

- Install a multi-channel filter to maintain air purity.

- Connect the appropriate pipe to the low-pressure control valve.

- Regular checks on pipes and valves will help maintain stable pressure.

4. Cooling System and Sealing Module

- The cooling system is vital for both the heater and the sealing module.

- Fill the water chiller tank to about 80% of its capacity.

- Connect water hoses securely to the heater, sealing module, water tank, and pump.

- Set the chiller temperature between 15–18°C.

- Regularly inspect connections for leaks and remove any scale buildup.

5. Jacketed Hopper and Temperature Control System (Optional)

- Connect the jacketed hopper to the water chiller using the proper hoses.

- Adjust the temperature control system to meet product requirements.

- Check all connection points for leaks.

- Ensure that heated circulating water maintains a consistent temperature.

6. Tube Trough

- Clean the tube trough thoroughly before assembly.

- Insert the support shaft into the designated rings.

- Secure all fixing screws tightly.

- Regular cleaning prevents residue buildup that could affect filling accuracy.

7. Barrel Cover and Auxiliary Components

- Carefully unpack the barrel cover to avoid damage.

- Clean the cover with a damp cloth before installation.

- Install the cover properly on the drum.

- If liquid level monitoring is required, ensure the photoelectric sensor is correctly installed before the cover is applied.

By following these maintenance tips, you can extend your machine’s lifespan and reduce downtime. Regular cleaning and timely repairs are key to keeping your production line running smoothly.

Conclusion

Tube filling machines revolutionize product packaging. They ensure fast, accurate, and hygienic filling processes that boost production efficiency. To recap, here are the five key points you must know:

- Definition and Application:A tube filling machine efficiently fills tubes with various products.

- Working Principle:The process—from feeding and filling to sealing—is fully automated and controlled.

- Types and Selection:Choose between semi-automatic, fully automatic, or rotary machines based on your needs.

- Technical Advantages and Trends:Automation offers speed, precision, and cost savings, while future trends promise even smarter systems.

- Maintenance and Upkeep:Regular maintenance is essential to keep your machine running efficiently and reliably.

Whether you are a startup or a large manufacturer, selecting the right tube filling machine and maintaining it properly gives you a competitive edge. Embrace the evolution of tube filling technology and upgrade your production line today. Stay ahead in a competitive market by focusing on efficiency, reliability, and innovation.