Panduan Terlengkap untuk Mesin Pencuci Botol – Penting untuk Lini Pengisian Cairan

Pelanggan mengunjungi Lini Pengemasan Farmasi di Grand

Analisis Mesin Farmasi Canggih – Penghitung Kapsul & Lainnya

Penghitung kapsul(SLDS-16D*2), pengurai dan pembersih botol (Grand-200C), penyegel pengering kelas atas adalah bagian dari rangkaian produk Grand.Dalam persaingan saat ini industri farmasi, mesin canggih sangatlah penting. Otomatisasi meningkatkan efisiensi dan meningkatkan kualitas produk. Dalam artikel ini, kami menyediakan analisis komprehensif mengenai produk mesin canggih kami. Setiap peralatan dirancang dan diproduksi sesuai dengan standar GMP nasional dan standar FDA AS. Mesin-mesin ini merupakan bukti kepemimpinan kami dalam teknologi Mesin Farmasi.

Mesin kami dibuat dengan mengutamakan presisi dan keandalan. Mesin ini ideal untuk industri farmasi, makanan, perawatan kesehatan, dan industri lainnya. Dalam artikel ini, kami membahas setiap produk secara terperinci. Kami juga menjelaskan bagaimana perangkat kami memenuhi standar industri tertinggi sekaligus memberikan kinerja yang luar biasa.

I. Tinjauan Umum Mesin Canggih Kami

Mesin canggih kami dirancang untuk memperlancar proses produksi. Setiap mesin dibuat dengan otomatisasi tingkat tinggi dan sistem kontrol yang canggih. Fitur utama peralatan kami meliputi:

- Otomatisasi Penuh:Setiap mesin menggunakan kontrol PLC dan antarmuka layar sentuh. Parameter dapat disesuaikan dengan mudah. Perintah yang singkat dan jelas memastikan respons yang cepat.

- Efisiensi Produksi Tinggi:Mesin kami dirancang untuk bekerja dengan kecepatan tinggi. Misalnya, Mesin Pembongkar Botol dan Pembersih dapat mencapai hingga 280 botol per menit.

- Keselamatan adalah yang utama:Fitur keselamatan seperti pelindung kaca plexiglass, fungsi penghenti pintu otomatis, dan berbagai sistem alarm melindungi operator.

- Perlindungan Lingkungan:Kami menggunakan mekanisme penggerak tertutup dan sistem transmisi tertutup. Hal ini mencegah kebocoran pelumas dan mengurangi pencemaran lingkungan.

- Keserbagunaan:Mesin kami dapat beradaptasi dengan berbagai bentuk botol dan kebutuhan pengemasan. Tidak perlu mengganti cetakan untuk botol bulat, persegi, atau datar.

- Standar Global:Semua peralatan mematuhi standar GMP dan FDA AS. Hal ini menjamin kualitas dan keamanan dalam setiap proses.

Fitur-fitur ini membuat mesin kami menonjol di dunia Mesin Farmasi. Apakah Anda memerlukan Mesin Pembuka dan Pembersih Botol atau sebuah Konter Kapsul & Tablet, produk kami memberikan presisi, kecepatan, dan keandalan.

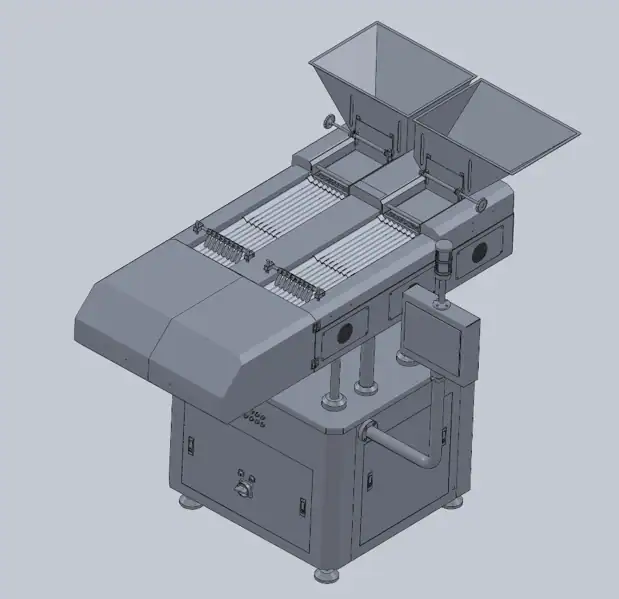

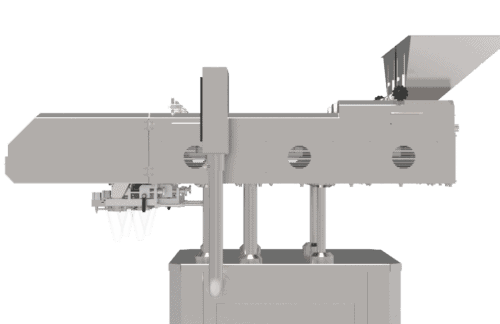

Jil. Agung-200C Mesin Pembuka dan Pembersih Botol Canggih

1. Pengenalan Produk

Grand-200C adalah mesin pengurai dan pembersih botol kelas atas. Mesin ini dirancang untuk memilah dan membersihkan botol dengan efisiensi yang tak tertandingi. Mesin ini dibuat untuk memenuhi standar GMP nasional dan FDA AS. Mesin ini menggunakan sistem kontrol PLC yang canggih, dan setiap parameter dapat disesuaikan melalui antarmuka layar sentuh yang intuitif.

2. Fitur Utama

Kecepatan Produksi Luar Biasa:

Grand-200C dapat memproses hingga 280 botol per menit. Produksi cepat sangat penting untuk operasi bervolume tinggi.

Desain Keamanan yang Ditingkatkan:

Pelindung plexiglass yang kuat melindungi operator. Fungsi penghentian otomatis pada pintu memastikan mesin berhenti saat pintu pengaman dibuka. Desain ini sangat meminimalkan risiko kecelakaan.

Pengoperasian yang Mudah Digunakan:

Tempat penyimpanan besar dengan fungsi pembuka pintu otomatis mengurangi kebutuhan untuk sering memuat botol secara manual. Ini mengurangi intensitas tenaga kerja.

Fleksibilitas dalam Penanganan Botol:

Tanpa perlu mengganti cetakan, mesin ini dapat menangani botol berbentuk bulat, persegi, dan pipih. Mesin ini mudah disesuaikan dengan berbagai kebutuhan pengemasan.

Memenuhi Persyaratan GMP:

Fungsi pembersihan udara terpadu menjamin botol dibersihkan secara menyeluruh. Hal ini penting untuk menjaga kemurnian produk.

Jaminan Kualitas Botol 100%:

Dengan fitur-fitur seperti penolakan botol otomatis, setiap botol yang diproses memenuhi kriteria kualitas yang ketat.

3. Spesifikasi Teknis

- Kapasitas Produksi Maksimum:60–280 botol per menit

- Spesifikasi Botol:Kisaran diameter dari 30 mm hingga 150 mm

- Tegangan/Frekuensi:Tegangan AC200V / 50Hz

- Kekuatan:90 kW

- Persyaratan Udara Terkompresi:3 MPa (3,5 juta kaki kubik)

- Dimensi (P×L×T):Ukuran 3330 × 1150 × 1850 mm

- Berat:900kg

Mesin Grand-200C ini adalah contoh utama dari mesin kelas atas Mesin Pembuka dan Pembersih BotolKinerjanya yang luar biasa dan desainnya yang serbaguna menjadikannya alat penting dalam setiap lini produksi farmasi modern.

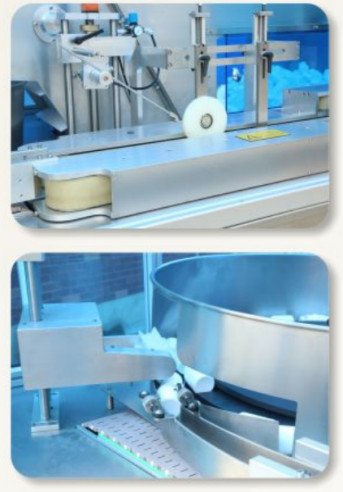

AKU AKU AKU. Agung-200CII Mesin Penyegel Agen Pengeringan Kelas Atas

1. Pengenalan Produk

Grand-200CII adalah mesin penyegel bahan pengering kelas atas. Mesin ini dirancang untuk memasukkan bahan pengering ke dalam botol secara otomatis. Proses ini penting untuk menjaga integritas dan masa simpan produk. Mesin ini menggunakan kombinasi sensor presisi dan kontrol PLC. Setiap parameter dapat disesuaikan melalui antarmuka layar sentuh.

2. Fitur Utama

- Penyesuaian Mudah:

Mesin ini dapat dengan mudah menyesuaikan dengan ketebalan bahan pengering yang berbeda. Hal ini mengatasi masalah umum berupa kesulitan kalibrasi pada peralatan sejenis. - Sistem Deteksi Terpadu:

Perangkat pendeteksi tidak adanya zat pengering yang dimasukkan meningkatkan proses kontrol kualitas. Ini meningkatkan tingkat kualifikasi produk secara keseluruhan. - Mekanisme Keamanan:

Fungsi penghenti pintu otomatis terpasang. Fitur ini memastikan keselamatan operator dengan menghentikan mesin saat pintu dibuka. - Keserbagunaan:

Dapat menangani berbagai ukuran botol. Cocok untuk botol dengan diameter 30–120 mm dan tinggi 30–200 mm.

Mesin Grand-200CII merupakan terobosan dalam teknologi penyegel bahan pengering. Mesin ini merupakan pelengkap yang sangat baik untuk lini produk kami Mesin Farmasi.

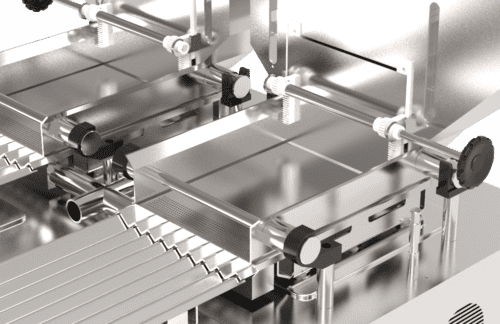

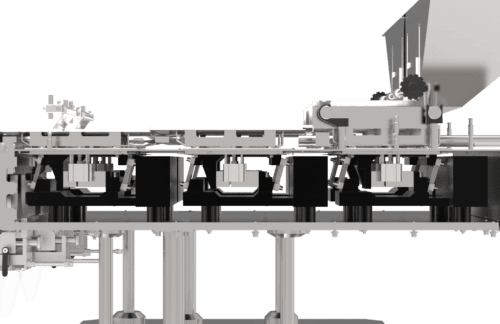

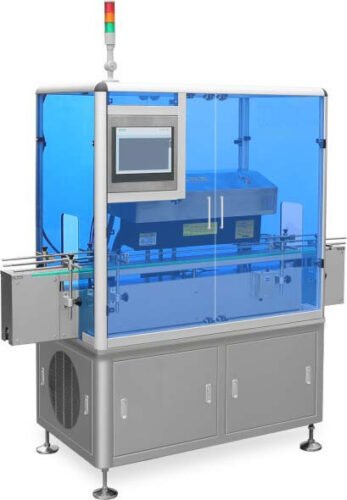

IV. Penghitung Pil Elektronik SLDS-16D*2 – Penghitung Kapsul & Tablet Terbaik

1. Pengenalan Produk

SLDS-16D*2 adalah penghitung pil elektronik canggih. Berfungsi sebagai penghitung pil presisi tinggi Konter KapsulMesin ini menggunakan desain modular yang terintegrasi dengan sensor optik dan sistem komputer mikro. Mesin ini mampu menghitung tablet, kapsul, pil bulat, dan kapsul lunak dengan presisi yang tak tertandingi.

2. Fitur Utama

Desain Modular:

Perangkat ini memiliki desain modular yang memungkinkan pembongkaran tanpa alat. Hal ini membuat perawatan dan pembersihan menjadi cepat dan mudah.

Penghitungan Presisi Tinggi:

Kombinasi sistem optik dan mikrokomputer menjamin akurasi penghitungan dalam 0,1‰. Hal ini sangat penting dalam bidang farmasi.

Pembersihan Otomatis:

Penghitung pil memiliki fungsi pembersihan otomatis untuk kepala penghitungnya. Ini memastikan bahwa debu dan kotoran tidak memengaruhi keakuratan sensor.

Sistem Penolakan Kesalahan:

Mesin ini secara otomatis menolak botol yang memiliki kesalahan penghitungan. Ini membantu menjaga standar kontrol kualitas yang tinggi.

Operasi Kebisingan Rendah:

Berkat inverter gelombang penuh dan modul getaran dengan desain pegas, perangkat ini beroperasi pada tingkat kebisingan setidaknya 10 dB lebih rendah daripada mesin sejenis.

Fitur Keselamatan:

Sensor internal mendeteksi jika tempat umpan kosong. Sistem memicu penghentian otomatis untuk mencegah kesalahan penghitungan atau kerusakan mesin.

Antarmuka yang Ramah Pengguna:

Semua parameter dapat diatur melalui layar sentuh berbahasa Mandarin. Namun, tersedia opsi multibahasa untuk melayani pengguna global.

3. Spesifikasi Teknis

- Jumlah Saluran Getaran:16 × 2 (dengan 4 saluran pembuangan)

- Kecepatan Produksi Maksimum:Hingga 20.000 tablet per menit (tergantung ukuran pil)

- Kisaran Pengisian:1 hingga 9.999 tablet per botol

- Spesifikasi Ukuran Pil:Ketebalan: 3–10 mm; Diameter: 3–20 mm; Panjang: 3–30 mm

- Diameter Botol:20–200 mm

- Tinggi Botol:40–240mm

- Tegangan/Frekuensi:Tegangan AC220V, 50/60Hz

- Kekuatan:5 kW

- Tekanan udara:6 MPa (1,5 Mpa)

- Dimensi (P×L×T):Ukuran: 1580 × 2060 × 1770 mm

- Kapasitas Hopper:70 liter

- Berat:Sekitar 700 kg

SLDS-16D*2 adalah teknologi mutakhir Konter Kapsul. Mesin ini banyak digunakan dalam lini produksi farmasi yang mengutamakan ketepatan dan kecepatan. Mesin ini memastikan bahwa setiap pil dihitung dengan benar, sehingga mempertahankan standar tinggi yang dibutuhkan dalam produksi farmasi.

Bahasa Indonesia: V. Agung-200R Mesin Tutup Putar

1. Pengenalan Produk

Grand-200R adalah mesin tutup putar yang canggih. Mesin yang sepenuhnya otomatis ini dirancang untuk memasang tutup botol dengan presisi tinggi. Mesin ini menggabungkan keunggulan desain internasional terkemuka. Mesin ini menggunakan sistem terpadu untuk mengurai botol, memposisikannya secara akurat, dan memasang tutup menggunakan kepala penutup magnetis atau torsi konstan.

2. Fitur Utama

Otomatisasi Penuh:

Grand-200R beroperasi secara otomatis dari pengisian botol hingga pengisian dan pengeluaran. Hal ini mengurangi tenaga kerja manual dan meningkatkan hasil produksi.

Aplikasi Tutup yang Tepat:

Kepala tutup magnetis menyesuaikan torsi pemasangan tutup. Ini memastikan tutup terpasang dengan aman tanpa merusak botol.

Keserbagunaan:

Mesin ini dapat memproses berbagai jenis botol bundar. Mesin ini mendukung berbagai diameter botol (hingga 100 mm) dan ukuran tutup botol (10 mm hingga 66 mm).

Mesin tutup putar Grand-200R merupakan bagian integral dari teknologi modern Mesin FarmasiEfisiensi tinggi dan desain serbaguna membuatnya ideal untuk berbagai lini produksi.

Bahasa Indonesia: VI. Agung-200Bahasa Inggris Mesin Penyegel Induksi Elektromagnetik Canggih (Berpendingin Air)

1. Pengenalan Produk

Grand-200E adalah mesin penyegel induksi elektromagnetik kelas atas. Mesin ini menggunakan medan elektromagnetik frekuensi tinggi untuk memanaskan lapisan aluminium foil dengan cepat. Panas tersebut melelehkan lapisan perekat, sehingga botol tertutup rapat tanpa kontak langsung. Metode penyegelan tanpa kontak ini cepat dan andal.

2. Fitur Utama

- Proses Penyegelan Cepat:

Mesin tidak memerlukan pemanasan awal. Operator dapat mengatur arus dan tegangan untuk mengendalikan kecepatan dan waktu penyegelan. - Output Daya yang Konsisten:

Catu daya switching yang dirancang khusus memastikan keluaran yang stabil. Konsistensi ini penting untuk mencapai segel yang andal. - Sistem Pendinginan yang Efisien:

Pendinginan air yang dikombinasikan dengan pendinginan udara paksa menjaga suhu kepala induksi tetap stabil. Desain ini mendukung operasi berkelanjutan dan berkecepatan tinggi. - Kontrol Cerdas:

Tampilan digital menunjukkan suhu dan pembacaan arus secara langsung. Antarmuka pengguna sederhana dan jelas, memastikan kemudahan pengoperasian.

Mesin penyegel induksi elektromagnetik kelas atas Grand-200E memberikan kinerja yang luar biasa. Teknologi canggihnya merupakan aset penting dalam Mesin Farmasi lini produksi yang memerlukan penyegelan berkecepatan tinggi dan andal.

VII. Keunggulan dan Daya Saing Pasar

1. Kustomisasi Kelas Atas yang Memenuhi Standar Global

Mesin kami dirancang untuk memenuhi standar GMP nasional dan FDA AS yang ketat. Apakah Anda memerlukan Mesin Pembuka dan Pembersih Botol atau sebuah Konter Kapsul & Tablet, produk kami memastikan hasil berkualitas tinggi. Pelanggan menikmati produk yang tidak hanya berkinerja andal tetapi juga memenuhi semua peraturan internasional.

2. Proses Produksi Sepenuhnya Otomatis

Mesin kami dibuat dengan mengutamakan otomatisasi penuh. Dengan kontrol PLC, layar sentuh, dan beberapa sensor, proses produksi berjalan lancar. Operator hanya perlu menyiapkan mesin satu kali. Seluruh proses—mulai dari membuka botol hingga menghitung, menutup, menyegel, dan memberi label—diotomatisasi. Hal ini mengurangi tenaga kerja manual dan meningkatkan efisiensi secara menyeluruh.

3. Fleksibilitas dan Kompatibilitas yang Tak Tertandingi

Peralatan kami serba guna. Peralatan ini dapat digunakan dalam berbagai industri termasuk farmasi, makanan, dan perawatan kesehatan. Desainnya memungkinkan mesin yang sama untuk memproses berbagai bentuk dan ukuran botol. Kompatibilitas ini memberi keunggulan kompetitif bagi mesin kami di pasar Mesin Farmasi.

4. Ramah Lingkungan dan Hemat Energi

Mesin kami menggunakan sistem transmisi tertutup. Desain ini mencegah kebocoran pelumas dan mengurangi polusi lingkungan. Sistem pendinginan canggih, seperti pada mesin penyegel induksi Grand-200E, memastikan efisiensi energi bahkan selama proses produksi yang panjang.

5. Komponen Kelas Dunia dan Layanan Purnajual Profesional

Kami menggunakan komponen-komponen yang terkenal secara internasional dari merek-merek seperti Siemens, Schneider, dan Panasonic. Ini memastikan bahwa setiap mesin dibuat agar tahan lama. Layanan purnajual kami juga tangguh. Kami menyediakan pelatihan teknis profesional dan dukungan cepat untuk menjaga kelancaran lini produksi Anda.

IX. Kesimpulan

Mesin canggih adalah tulang punggung produksi farmasi modern. Jajaran produk kami mencakup peralatan canggih seperti Mesin Pembersih dan Pembuka Botol (Grand-200C), itu Penghitung Kapsul & Tablet (SLDS-16D*2), mesin tutup putar, mesin penyegel induksi elektromagnetik, dan mesin pelabelan berperekat. Semua mesin kami sepenuhnya otomatis, aman, dan ramah lingkungan, serta memenuhi dan melampaui standar GMP dan FDA global.

Peralatan kami dirancang untuk produksi berkecepatan tinggi, operasi yang presisi, dan fleksibilitas. Perusahaan yang menggunakan peralatan kami Mesin Farmasi lihat peningkatan signifikan dalam efisiensi, kualitas, dan pengurangan biaya tenaga kerja. Baik Anda memerlukan penghitungan kapsul yang canggih atau penguraian dan pembersihan botol yang efisien, solusi kami dirancang untuk memenuhi tuntutan produksi modern dengan keandalan dan keberlanjutan lingkungan.

Berinvestasi pada mesin canggih kami akan mengubah lini produksi Anda dengan meningkatkan output dan meningkatkan integritas produk. Jelajahi portofolio kami dan temukan bagaimana kami Konter Kapsul & Tablet dan mesin lainnya dapat membawa produksi Anda ke tingkat berikutnya. Hubungi kami hari ini untuk informasi lebih lanjut dan rasakan keunggulan produksi otomatis.

Panduan ini menyoroti fitur-fitur utama dan wawasan teknis dari mesin canggih kami. Tingkatkan lini produksi Anda dengan peralatan yang dirancang untuk memenuhi standar industri tertinggi.