遅延放出型と腸溶性コーティング型:グランドパックガイド

究極のガイド:保護とブリスター包装ソリューション | GrandPack

導入

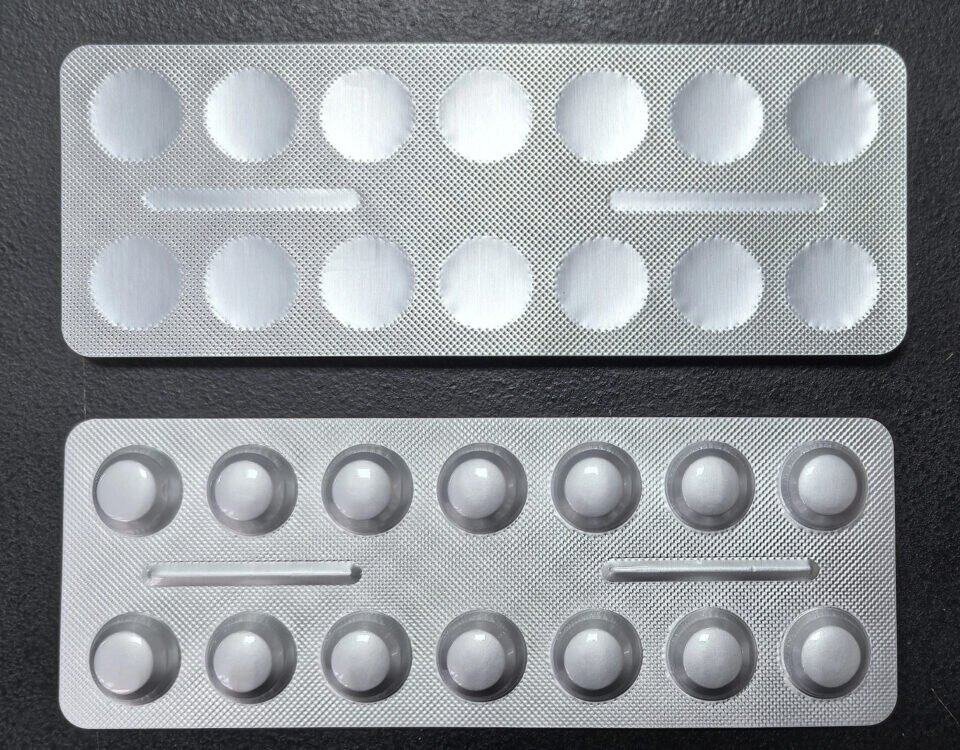

Take a walk down any pharmacy or electronics aisle, and you’ll be surrounded by one of the most effective and ubiquitous forms of packaging in the modern world: the ブリスターパック. From life-saving medications to the batteries that power our devices, this humble combination of thermoformed plastic and a backing material is a powerhouse of protection, safety, and marketing. But what makes this type of ブリスター包装 so indispensable across countless industries? The answer lies in a masterful blend of security, integrity, and user-centric design.

As experts in providing comprehensive Blister Packaging Solutions, we at GrandPack understand the intricate science and engineering that go into creating the perfect package. This guide will unpack the layers of the common blister pack, exploring why it’s not just a container, but a critical component of product delivery. We'll delve into its many advantages, the materials that give it strength, and the sophisticated ブリスター包装機械 required to bring it to life.

The Core Function: Unparalleled Product Protection

At its heart, the primary purpose of any blister package is to protect its contents from the outside world. This is where blister technology truly excels, offering a multi-layered defense system against a host of potential threats.

Defense Against Physical Damage

The journey from the factory to the consumer's hand is fraught with peril. Products can be dropped, crushed, and rattled during shipping and stocking. A well-designed ブリスターボックス or pack features a rigid, pre-formed plastic cavity that closely encases the product. This cavity acts like a suit of armor, absorbing impacts and preventing abrasions, breakage, or deformation. Unlike a simple box or a ブリスターバッグ, which offers minimal structural support, the blister’s rigid shell provides a crucial buffer against the rigors of transit and retail handling.

Creating a Barrier Against the Elements

Beyond physical threats, invisible enemies like moisture, oxygen, light, and contaminants pose a significant risk to many products, especially pharmaceuticals and food items.

- Moisture and Oxygen: For medications, exposure to humidity and oxygen can trigger chemical degradation, reducing the drug's potency and shelf life. A properly sealed blist pack made from high-barrier plastics (like Aclar®) and foil lidding creates an impermeable seal around each individual dose, guaranteeing its stability until the moment of use.

- UV Light: Many active pharmaceutical ingredients (APIs) are light-sensitive. Opaque or UV-resistant plastics and foils can be used to create blister packs that shield the contents from harmful UV radiation, preventing photodegradation.

- Contamination Control: Each product is housed in its own individual, sealed cavity. This compartmentalization is a game-changer for hygiene and safety. It prevents contamination from dust, microbes, and human tampering, and it also means that accessing one unit doesn't compromise the sterility or integrity of the others.

Safety and Trust: The Tamper-Evident Advantage

In an age of heightened consumer safety concerns, trust is paramount. Blister packs are a frontline defense against tampering and counterfeiting. To access the product, a consumer must physically and permanently break the seal by pushing the product through the foil backing or peeling the lidding.

This built-in tamper evidence is immediately obvious. A punctured or peeled blister serves as a clear visual warning to the consumer that the product may have been compromised. This feature is not just a suggestion; it's a regulatory requirement for over-the-counter drugs, mandated by agencies like the FDA. It provides peace of mind for consumers and a layer of liability protection for manufacturers. A simple ブリスターカード with this feature is one of the most effective security tools in retail.

Precision and Patient Adherence: The Pharmaceutical Powerhouse

Nowhere are the benefits of the ブリスターパック more critical than in the pharmaceutical industry. The design directly addresses one of healthcare's biggest challenges: patient medication adherence.

- Dosage Accuracy and Clarity: Each pill or capsule is presented in its own distinct pocket. This eliminates confusion and makes it easy for patients, especially seniors or those on multiple medications, to track their intake. There's no guesswork involved with shaking pills from a bottle.

- Calendarized Packaging: Many ブリスターパック are printed with days of the week or other time-based markers next to each cavity. This "compliance packaging" or "memory packaging" provides a simple visual cue, helping patients remember if they've taken their daily dose and improving overall adherence to the treatment regimen.

- Professional and Clinical Appearance: The clean, orderly, and sealed nature of blister packaging lends a professional and hygienic feel that builds patient confidence in the medication they are taking. This is a stark contrast to loose pills in a bottle. The German term blisterverpackung is synonymous with this level of precision and quality in the medical field.

More Than Just a Shell: The Marketing and Branding Opportunity

While protection and safety are functional benefits, the ブリスターカード is also a powerful marketing tool. The paperboard or foil backing provides a generous canvas for branding and communication.

Unlike a small bottle label, a blister card offers ample space for:

- High-Impact Graphics and Logos: Attract consumer attention on a crowded retail shelf.

- Essential Information: Clearly display dosing instructions, ingredients, warnings, and expiration dates in an easy-to-read format.

- Promotional Messaging: Include QR codes linking to websites, highlight special features, or run promotions directly on the package.

- Hang-Hole Versatility: The integrated hang-hole on most blister cards allows for flexible and prominent retail display, maximizing product visibility.

Blister card packaging machines-DGX-380 by GrandPack

Blister card packaging machines-DGX-380 by GrandPack

This ability to combine a protective shell with a marketing billboard makes the blister package an incredibly efficient and cost-effective choice for consumer-packaged goods (CPGs).

The Backbone of Production: Blister Packaging Machinery

Creating millions of identical, perfect blister packs requires automation and precision. This is the domain of ブリスター包装機械. These sophisticated machines are the unsung heroes of the packaging world, performing a seamless sequence of complex operations.

A typical blister line process includes:

- Forming: A roll of plastic film (like PVC, PVDC, or PET) is heated to make it pliable and then vacuum- or pressure-formed into the custom-designed cavities or "blisters."

- 充填: The machine's automated filling station accurately drops the product—be it a tablet, capsule, battery, or toy—into each cavity. Vision systems are often used here to ensure every cavity is correctly filled.

- シーリング: A roll of lidding material (typically aluminum foil or paperboard) is placed over the filled cavities. Heat and pressure are then applied by a sealing station to bond the lidding material to the plastic film, creating a secure seal around each blister.

- Perforating and Cutting: The sealed web of packs is then perforated, printed with batch codes and expiration dates, and cut into its final size, whether it's an individual ブリスターカード or a sheet of multiple packs.

Blister packing machine(Liquid)-GrandPack

The speed, reliability, and precision of this machinery are what enable manufacturers to produce safe, effective, and affordable goods at scale. Companies like GrandPack specialize in providing these end-to-end Blister Packaging Solutions, from machine selection to installation and support.

Frequently Asked Questions (FAQs) About Blister Packaging Machinery

1. What are the main types of blister packaging machines available? There are generally two main types based on their operational process: rotary and flat-plate machines.

- Rotary Machines: Use a rotating drum for the forming and sealing processes. They are known for their extremely high speeds and are best suited for large, continuous production runs of a single product.

- Flat-Plate (or Platen) Machines: Use flat plates to heat and seal. They operate intermittently (stop-and-go). While typically slower than rotary machines, they offer greater flexibility, are easier to change over for different products, and are excellent for smaller to medium-sized batches and complex blister shapes.

2. How does a blister machine handle different product shapes and sizes? Versatility is achieved through change parts. The "forming die" (which shapes the blister cavity) and the "sealing die" are specific to each product's shape and layout. On a modern blister machine, these parts are designed for quick and easy changeovers. An operator can swap out the tooling in a relatively short amount of time to switch production from, for example, a small round tablet to a large oblong capsule.

3. What materials can be used on a standard blister packaging machine? Most modern blister machines are incredibly flexible and can handle a wide range of forming films and lidding materials.

- Forming Films: Common plastics include PVC (the most common and cost-effective), PVDC (PVC coated for better moisture/oxygen barrier), PET (good for clarity and strength), and high-barrier films like Aclar® (for extremely sensitive drugs).

- Lidding Materials: The most common is push-through aluminum foil, but options also include peelable foil, paper-foil laminates, and child-resistant (CR) specialty lidding.

4. What are the most important quality control features on blister packaging machinery? Modern machines integrate several automated QC systems to ensure 100% compliance. Key features include:

- Pinhole Detection: Systems that can detect microscopic holes in the aluminum foil lidding that would compromise the seal.

- Vision Inspection Systems: Cameras that check for mis-shaped tablets, incorrect colors, empty cavities, or foreign debris before sealing.

- Code Verification: Scanners (OCR/OCV) that read the printed batch codes and expiry dates to ensure they are correct and legible. Any pack that fails these checks is automatically rejected from the line.