Машина для наполнения и запечатывания инфузионных пакетов | Решения для точных инфузионных мягких пакетов и пластиковых бутылок

Машина для наполнения и запечатывания инфузионных мешков Grand обеспечивает высокоточное автоматизированное наполнение и запечатывание мягких инфузионных мешков и пластиковых бутылок. Соответствующая стандартам GMP, FDA и CE, наша система поддерживает различные объемы, стерильное наполнение и высокобарьерные упаковочные решения.

Инновационные решения по наполнению и запечатыванию инфузионных пакетов

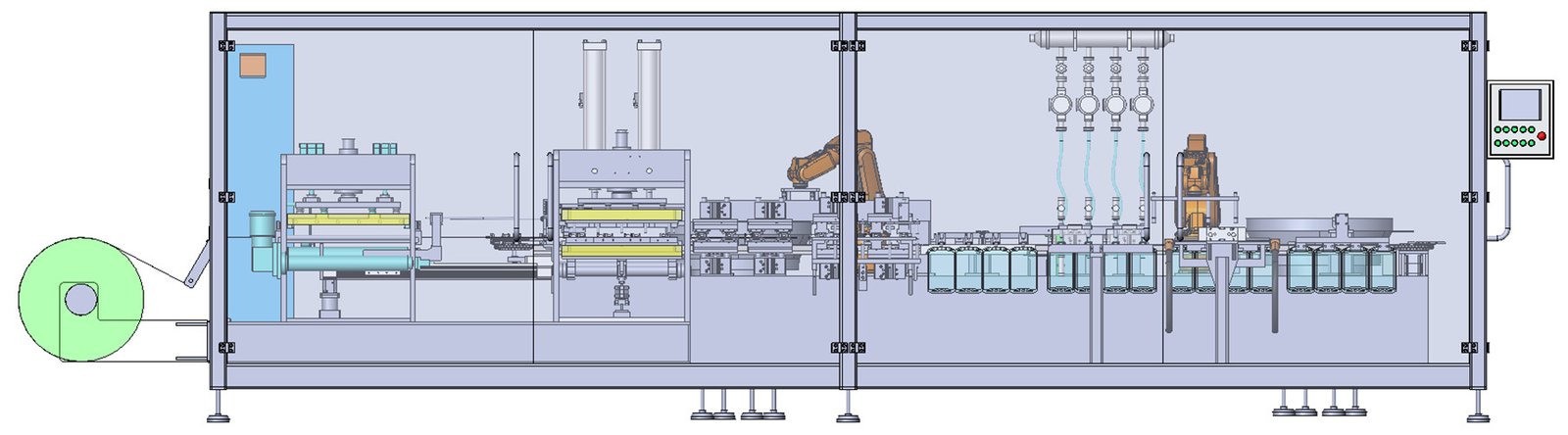

Машина для наполнения и запечатывания инфузионных мешков

Гранд's Машина для наполнения и запечатывания инфузионных мешков это передовая система фармацевтической упаковки, разработанная для инфузионные мягкие пакеты и пластиковые бутылки.

Наше решение объединяет автоматизацию, точное дозирование и стерильную герметизацию для обеспечения максимальной безопасности и эффективности продукции.

Высокий стандарт и высокая эффективность

Благодаря возможности обработки продуктов объемом от 30 до 5000 мл эта система обеспечивает универсальность, соответствие требованиям GMP и Управление по контролю за продуктами и лекарствами (FDA)- соответствующий требованиям процесс розлива, повышающий эффективность производства и целостность продукта.

Независимо от того, работаете ли вы с многослойными инфузионными пакетами, изготовленными не из ПВХ, или с пластиковыми инфузионными бутылками, наша машина гарантирует равномерное, чистое наполнение и надежную герметизацию.

Основные моменты наполнения инфузионных мешков

✅ Двойное наполнение продукта за цикл для повышения производительности

✅ Возможность настройки под различные формы продукта и объемы

✅ Возможности термосваривания для превосходной безопасности упаковки

✅ Удалённое устранение неполадок для эффективности работы

✅ Интегрированная система RAB для асептического розлива

✅ Горячее тиснение номера партии в режиме реального времени

✅ Расширяемая функциональность для будущих производственных нужд

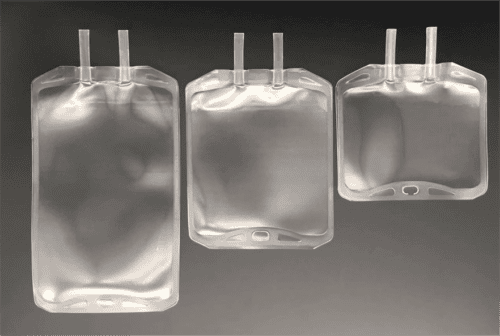

Мешок для инфузий из не-ПВХ

Безопасная, стерильная и экологичная упаковка

Грандс инфузионные пакеты не из ПВХ производятся в Чистое помещение класса C с использованием многослойная соэкструдированная инфузионная пленка. Наша упаковка, разработанная для обеспечения безопасности и стабильности, обеспечивает:

✔ Превосходная химическая стабильность без извлекаемых веществ

✔ Нетоксичные материалы, не содержащие ДЭГФ для безопасности пациентов

✔ Совместимость с терминальной стерилизацией при 121°C

✔ Варианты стерилизации облучением для асептического розлива

✔ Уровень эндотоксина ниже 25ЕЭ/мл

✔ Чистая, прочная упаковка с увеличенным сроком хранения

✔ Соответствие национальным и международным стандартам

✔ Доступны в различных объемах (50-3000 мл)

Идеальные области применения инфузионных пакетов, изготовленных не из ПВХ:

- Стандарт растворы для внутривенного вливания

- Перитонеальный диализ и ирригационные жидкости

- Медицинские повязки из полисахаридного волокна

- Лечебное питание на основе пектина и белка

- Среды для культивирования клеток и разбавители вакцин

- Отвары традиционной китайской медицины

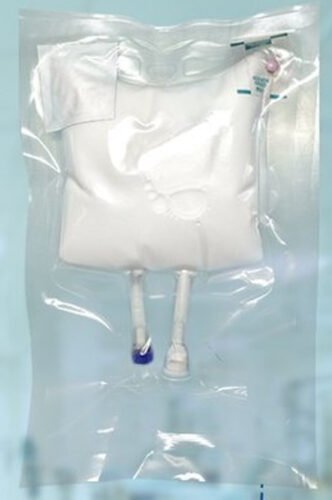

Внешние пакеты с высоким барьером

Максимальная защита упаковки для инфузий

Для сохранения стабильности препарата и продления срока годности компания Grand предлагает высокобарьерные внешние пакеты с исключительными защитными свойствами:

✔ Высокая прозрачность для придания продукту первоклассного внешнего вида

✔ Выдерживает стерилизацию в автоклаве при температуре 121°C.

✔ Превосходный кислородный барьер для предотвращения окисления

✔ Сопротивление водяному пару для поддержания концентрации препарата и баланса pH

✔ Антибактериальные свойства для предотвращения загрязнения

✔ Доступны индивидуальные рецептуры для конкретных фармацевтических применений

Наша высокобарьерная упаковка особенно подходит для Лечебные препараты, аминокислоты и инъекции китайской медицины, гарантируя целостность продукта и безопасность пациентов.

Трансформируйте процесс упаковки инфузионных растворов

Грандс Машина для наполнения и запечатывания инфузионных мешков сочетает в себе передовые технологии со строгими GMP, FDA и Соответствие CE.

Будь то оптимизация существующих производственных линий или внедрение Решения для инфузионных мешков, не содержащих ПВХ, мы предоставляем Индивидуально разработанные, эффективные и стерильные системы фармацевтической упаковки для удовлетворения меняющихся потребностей отрасли.

Свяжитесь с нами сегодня для консультации и изучения лучших вариантов Решения для упаковки инфузионных растворов с учетом ваших потребностей.

Линия по производству инфузионных пакетов