Grand Heat Shrink System -The Final Touch

Your Product's Guardian.

After the remarkable journey from concept to creation, your product deserves one final, uncompromising layer of protection. This is more than packaging. It's a commitment to the craft you've perfected. It's the promise that every unboxing is as flawless as you intended.

The Grand Heat Shrink System reimagines this final step with a revolutionary design philosophy and an unwavering standard of engineering. It fuses powerful protection, seamless automation, and elegant industrial design to forge an impenetrable, transparent fortress for your products.

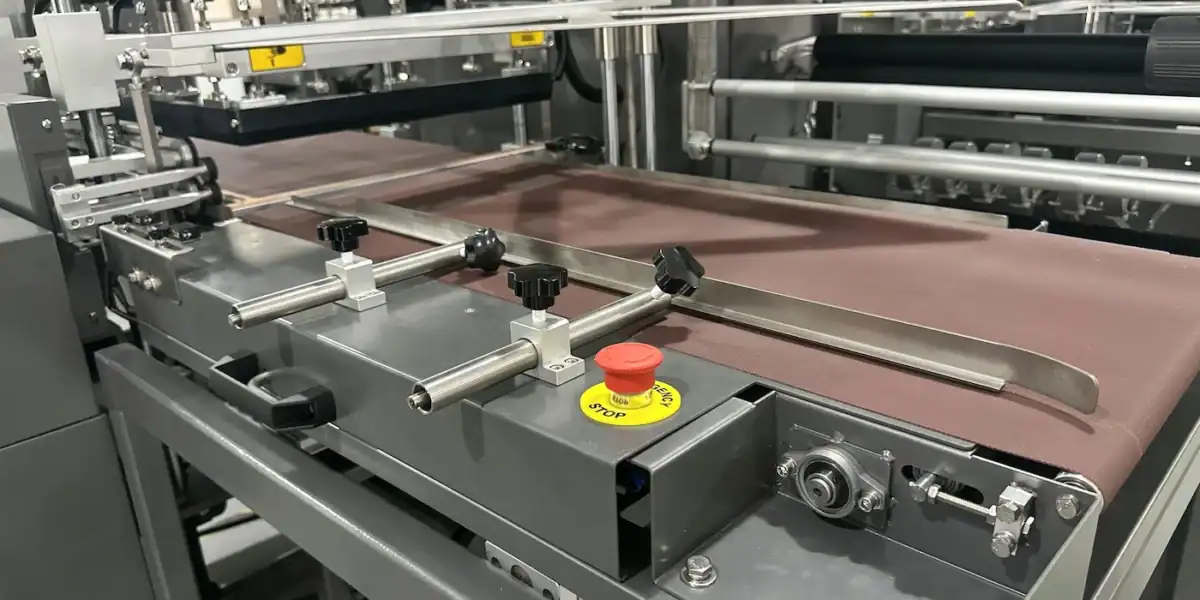

Sealing - A Flawless Seal. Every Time.

А perfect package begins with a perfect seal. Гранд is obsessed with the precision of this moment. Where traditional L-bar designs often compromise between speed and stability, our Vertical Sealing System fundamentally solves the equation.

With calculated poise and precision, it applies uniform pressure and exact heat, creating a seal that is nearly invisible yet impossibly strong. It’s a bond that is both aesthetically clean and structurally sound.

Engineered for Endurance.

We know that any pause on the production line is a cost. That’s why we engineered endurance into every component. From the robust mechanical frame to the world-class electrical architecture—featuring industry leaders like Omron PLCs and sensors, Schneider switches, and Panasonic VFDs—we select only the partners proven to withstand the test of time. The result is a system with an exceptionally low failure rate, built to perform day in and day out in the most demanding environments, becoming the most trusted member of your production team.

Shrink Tunnel - The Art of Shrink.

Perfected by Air and Heat.

As the package enters the ZF-S550-L Shrink Tunnel, an intelligently choreographed thermal dance begins. This is not just a heat chamber; it is a smart thermodynamic environment.

Our proprietary Downward-Circulating Airflow System acts as a master conductor, guiding heated air to every surface of the package with absolute precision. Heat is no longer blasted; it is gently and evenly enveloped. This design ensures a perfectly uniform shrink, whether your product is a flat carton or an irregular shape, delivering a tight, flawless finish with zero wrinkles.

Efficiency is in its DNA. In our pursuit of a perfect result, we never lose sight of efficiency. An innovative thermal recirculation technology locks in every degree of heat, minimizing energy waste. This means faster warm-up times, lower energy consumption, and a smaller carbon footprint. You have total control to adjust the airflow, direction, and conveyor speed, allowing you to dial in the optimal shrink profile for any product in minutes. And it’s all guarded by an intelligent temperature control system that maintains stability within an exacting ±1°C.

Control & Integration - Simplicity in Command.

- Powerful performance should not come at the price of complexity. We’ve distilled complex control logic into an intuitive, high-definition touchscreen interface. The UI is clean, the command hierarchy is logical, and your team can achieve mastery with minimal training.

- From sealing temperature to conveyor speed, every critical parameter is just a touch away. Once your settings are dialed in, the machine operates with autonomous stability, freeing your team from constant oversight. This is more than convenience; it’s a new level of productivity.

- Seamlessly into Your Workflow. We believe a new machine should be a seamless extension of your line, not an isolated island. The Grand Heat Shrink System is designed with this principle at its core. An adjustable conveyor height, variable speed controls, and standardized communication protocols allow it to physically and digitally handshake with your upstream equipment, like cartoners, and your downstream systems. It becomes a harmonious and powerful part of your automation landscape.

The Grand Ecosystem - Beyond the Wrap. The Full Journey.

A perfect shrink-wrapped bundle is a milestone, but it isn't the end of the journey. Once protected, your products need to be cased, palletized, and prepared for the world.

This is the power of the complete Grand automation ecosystem.

From Case to Pallet. In One Unbroken Stream. Imagine your pristine, shrink-wrapped bundles flowing from the tunnel directly into our Automatic Case Packer. It intelligently collates the products, erects a shipper case, and gently loads the bundles before sealing it for transit. From there, an Intelligent Robotic Palletizer takes the finished cases and, following a pre-set pattern, builds a perfect, stable pallet.

Make progress together

We believe superior productivity is born from an integrated design philosophy. Let's build the future of your production line. Together.

Почему стоит выбрать Гранд?

- Передовые технологии

Запатентованные механизмы микродробления с вертикальным валом и отраженного удара обеспечивают непревзойденную стабильность. - Высокая эффективность и производительность

Оптимизированная конструкция ротора снижает потребление энергии и одновременно повышает производительность. - Безопасность и соответствие

Кнопки аварийной остановки, защищенные панели доступа и опции, соответствующие стандарту ATEX, для опасных зон. - Глобальная сеть поддержки

Сервисные центры в Северной Америке, Европе и Азии. Опытные специалисты готовы помочь. - Настраиваемые решения

От установок, монтируемых на раме, до полностью автоматизированных линий — адаптируйте свою систему под конкретные технологические потребности.

Детали машины

Часто задаваемые вопросы

1. What types of shrink film can Grand's heat shrink machine handle?

Our machines are highly versatile and designed to work with all major types of shrink film, including Polyolefin (POF), Polyethylene (PE), and Polyvinyl Chloride (PVC). POF is the most common for pharmaceutical and retail applications due to its excellent clarity and strength, while PE is often used for heavier bundling applications. We can help you determine the optimal film for your specific product and needs.

2. How does the machine ensure a consistently high-quality seal on every package?

Consistency is achieved through a combination of superior engineering and premium components. The vertical sealing mechanism provides a stable and powerful motion, while the high-quality heating elements and Omron temperature controllers maintain the sealing blade at a precise, unwavering temperature. This synergy guarantees a strong, clean, and reliable seal every time.

3. Is the heat shrink machine difficult to operate and maintain for our staff?

Not at all. The system is designed with a user-friendly philosophy. An intuitive HMI, powered by an Omron PLC, simplifies setup and operation. After a brief training session, operators can confidently run and adjust the machine. Furthermore, by using internationally recognized components from brands like Panasonic и Schneider, troubleshooting and maintenance are streamlined, as spare parts and support are widely available.

4. How does Grand's heat shrink machine contribute to energy savings?

The ZF-S550-L shrink tunnel is specifically engineered for energy efficiency. Its advanced thermal recirculation system traps and reuses hot air within the chamber, significantly reducing the energy needed to maintain the target temperature. This not only lowers your operational costs but also contributes to a more sustainable manufacturing footprint.

5. Can this heat shrink system be integrated into our existing packaging line?

Yes. Integration is a key design consideration. Both the sealer and the tunnel feature adjustable conveyor heights and variable speeds, allowing them to be synchronized with your existing upstream and downstream equipment. The use of standard industrial control systems like a PLC also facilitates easy communication and handshaking with other machines on your line.

6. Beyond this machine, how does Grand support our entire end-of-line packaging process?

Grand specializes in providing complete, turnkey solutions. Our expertise doesn't stop at shrink wrapping. We design and manufacture a full suite of end-of-line equipment, including automatic case packers и robotic palletizers, that integrate seamlessly with our heat shrink systems. This allows us to offer you a single-source solution for a fully automated packaging process, from individual product to shipment-ready pallet.

Связаться с нами