11 крупнейших производителей эмульгаторов для миксеров в мире (2025 г.)

Пять отраслей, которые изменило появление термоусадочной упаковочной машины

Полное руководство по машинам для печати на капсулах и таблетках | Grand

Почему вашей фармацевтической линии нужна машина для печати на капсулах и таблетках

В мире, где два разных лекарства могут выглядеть поразительно похожими, как обеспечить безопасность пациентов и целостность бренда? Ответ кроется не только в формуле, но и в самой сути продукта. Простой и понятный идентификатор может стать определяющей чертой между правильной дозировкой и критической ошибкой, между надежным брендом и опасной подделкой. Именно здесь современный машина для печати на капсулах и таблетках становится незаменимым активом, превращая простую таблетку в понятный, безопасный и профессиональный продукт.

В компании Grand мы понимаем, насколько важна каждая деталь на фармацевтическом производстве. Высокопроизводительная машина для печати на капсулах и таблетках Это больше, чем просто оборудование; это краеугольный камень контроля качества, укрепления бренда и доверия пациентов. В этом руководстве мы рассмотрим важнейшую роль этих аппаратов, принципы их работы и то, на что следует обращать внимание при их интеграции в ваше учреждение.

Важнейшие преимущества печати на фармацевтических препаратах

Печать на таблетках и капсулах — это нормативные требования и стратегическая необходимость. Нанесение логотипа, информации о дозировке или кода, казалось бы, простое действие, обеспечивает комплекс преимуществ, которые ощущаются как на производстве, так и на конечном потребителе.

1. Безошибочная узнаваемость продукта и безопасность

Основное преимущество использования машина для печати на капсулах и таблетках повышает безопасность пациентов. Такие организации, как Институт безопасной медицинской практики (ISMP), давно подчеркивают опасность препаратов с похожими названиями (LASA), которые часто являются причиной врачебных ошибок. Нанося уникальные идентификаторы непосредственно на лекарственную форму, вы обеспечиваете мгновенную визуальную подсказку для медицинских работников и пациентов.

- Предотвращение ошибок: Напечатанный код или название помогают фармацевтам, медсестрам и пациентам быстро убедиться в том, что они получили нужное лекарство, что значительно снижает риск путаницы.

- Идентификация в чрезвычайной ситуации: В случае случайной передозировки или отравления четкая маркировка на таблетке или капсуле позволяет спасателям быстро идентифицировать вещество, что приводит к более быстрому и эффективному лечению.

2. Эффективная дифференциация бренда и борьба с подделками

На конкурентном рынке ваш бренд — это залог доверия потребителей. Печатные капсулы и планшеты являются мощным инструментом для создания такого доверия.

- Идентичность бренда: Чёткий, понятный логотип или товарный знак превращает ваш продукт из обычного лекарства в узнаваемый бренд. Это укрепляет доверие потребителей и выделяет ваш продукт на переполненных аптечных полках.

- Надежный барьер для подделок: К сожалению, мировой рынок переполнен контрафактными фармацевтическими препаратами, представляющими серьёзную угрозу общественному здоровью. Подделкам сложно точно воспроизвести высококачественный и сложный отпечаток. планшетные принтеры можно применять замысловатые дизайны и многоцветные логотипы, которые служат первой линией обороны, защищая как репутацию вашего бренда, так и здоровье пациентов.

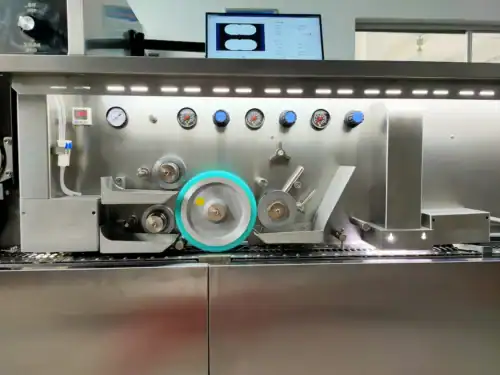

Машина для печати на капсулах и таблетках Grand YDL-3000V2

3. Повышение лояльности клиентов и конкурентоспособности

Профессионально представленный продукт свидетельствует о качестве. Когда пациенты легко идентифицируют ваш препарат и доверяют ему, это способствует повышению лояльности. Визуальное единообразие во всех ваших линейках продукции подтверждает приверженность вашей компании качеству и профессионализму, повышая общую конкурентоспособность ваших лекарственных средств.

Под капотом: как работает машина для печати на капсулах и таблетках

Технология фармацевтической печати — это сложный процесс, известный как офсетная ротационная печать. Она разработана для высокой скорости, точности и стабильности, гарантируя соответствие каждой единицы продукции строгим стандартам. Процесс можно разделить на несколько ключевых этапов:

- Кормление: Процесс начинается с бункера, в котором находятся таблетки или капсулы. Высокоточная система подачи, часто представляющая собой вращающийся диск с ячейками, размер которых соответствует конкретному продукту, тщательно ориентирует и перемещает каждый элемент по отдельности в печатный тракт.

- Гравюра чернилами: Сердце машины — ротогравюрный цилиндр. Это тщательно отполированный металлический цилиндр (часто из нержавеющей стали), на котором тщательно гравируется желаемый рисунок — логотип, текст или код.

- Чернила: Этот гравированный цилиндр вращается в резервуаре с фармацевтическими пищевыми чернилами. Гравированные участки заполняются чернилами.

- Врачевание: Когда цилиндр вращается из резервуара с чернилами, он проходит через «ракельный нож». Этот прецизионный нож соскребает излишки чернил с гладкой поверхности цилиндра, оставляя чернила только в пределах гравированного узора.

- Смещение переноса: Чернила не наносятся непосредственно на таблетку. Вместо этого гравированный цилиндр переносит чернильный рисунок на мягкий, гибкий резиновый офсетный валик. Этот промежуточный этап обеспечивает чёткую и полную печать даже на изогнутых или неровных поверхностях таблеток и капсул.

- Печать: Таблетки или капсулы, двигаясь по конвейеру, попадают под резиновый офсетный валик с краской. Валик мягко контактирует с поверхностью, обеспечивая безупречный перенос отпечатка краски на каждый продукт.

- Сушка и выгрузка: После печати изделия продолжают движение по конвейеру, давая чернилам полностью высохнуть, прежде чем они выгружаются через желоб для сбора и последующей упаковки.

Современные машины, такие как ГрандYDL-3000V2 от компании может достигать невероятной производительности. В зависимости от размера и формы изделия, эти системы могут печатать где угодно: от 80 000 до более 120 000 единиц в час, что делает их пригодными даже для самых требовательных масштабов коммерческого производства.

Расшифровка технологии: возможности и параметры печати

Не все виды печати одинаковы. Продвинутый планшетные принтеры обеспечивают исключительную универсальность для удовлетворения разнообразных требований к продукции и брендингу.

- Аксиальная и кольцевая печать: Вы можете выбрать ориентацию печати. Аксиальная печать размещает отметку линейно по всей длине капсулы. Кольцевая (или радиальная) печать оборачивает печать по всей окружности капсулы.

- Одноцветная и двухцветная печать: Хотя одноцветная печать является стандартной, возможности двухцветной печати открывают новые возможности брендинга. машина для печати капсул с помощью этой функции можно одновременно печатать разные цвета на крышке и корпусе капсулы, создавая отличительный и запоминающийся вид.

- Направленная печать: Сложные системы могут ориентировать капсулы таким образом, чтобы определенное сообщение было идеально совмещено на корпусе, а другое — на крышке, что позволяет создавать более сложные и информативные конструкции.

Эти опции позволяют печатать логотипы, товарные знаки, информацию о дозировке, матрицы данных и штрихкоды, обеспечивая уровень настройки, который соответствует практически любым нормативным или маркетинговым требованиям.

Выбор машины: ключевые характеристики успеха

При инвестировании в машина для печати на капсулах и таблеткахВы инвестируете в критически важный контрольный пункт своего производства. Вот ключевые факторы, которые следует учитывать:

- Выходная мощность: Оцените ваши текущие и будущие производственные потребности. Требования к оборудованию для научно-исследовательской лаборатории будут отличаться от требований к оборудованию для крупного коммерческого предприятия. Ищите оборудование, диапазон производительности которого соответствует объёмам вашей партии.

- Материалы и соответствие: Машина должна быть изготовлена в соответствии с фармацевтическими стандартами. Обратите внимание на прочную раму, изготовленную из нержавеющая сталь 316L на всех контактных частях, чтобы предотвратить загрязнение и обеспечить долговечность. Машина должна быть Соответствует cGMP (действующим стандартам надлежащей производственной практики) и соответствуют стандартам качества, таким как ISO 9001 и CE.

- Универсальность и переналаживаемость: Может ли машина обрабатывать весь спектр форм и размеров продукции? Насколько быстро и легко вы сможете переналадить производство с одного продукта на другой? Современные конструкции обеспечивают быструю замену деталей, таких как подающие диски и ролики для ротационной глубокой печати, без использования инструментов, чтобы минимизировать время простоя.

- Цифровая интеграция и простота использования: Выбирайте машину с удобным человеко-машинным интерфейсом (HMI), например, с сенсорной панелью. Это упрощает эксплуатацию, позволяет легко настраивать параметры (например, скорость, давление) и обеспечивает диагностику и подсчёт продукции в режиме реального времени. Такие функции, как автоматическая сигнализация о нехватке материалов, также бесценны.

- Репутация производителя: Сотрудничайте с таким производителем, как Grand, который известен качественным проектированием, надежной работой и превосходной послепродажной поддержкой.

Создание бесперебойного рабочего процесса: интеграция с вашей производственной линией

Печатная машина не работает в вакууме. Она — важнейшее звено в длинной производственной цепочке. После того, как вы... печатные капсулы или таблетки должны быть идеально маркированы и проверены, они должны быть надежно и эффективно упакованы.

Именно здесь комплексный подход к вашей производственной линии приносит свои плоды. Компания Grand специализируется на предоставлении комплексных решений, обеспечивающих плавную интеграцию от одного этапа к другому.

- Печать: Процесс начинается с высокоскоростной машины, такой как Капсульный и планшетный принтер YDL-3000V2.

- Упаковка: Свежеотпечатанную и высушенную продукцию можно сразу подавать на следующий этап. Для максимальной защиты и презентабельного вида рекомендуется использовать Высокоскоростные блистерные упаковочные машины GrandЭти машины запечатывают вашу продукцию в индивидуальные блистеры с контролем первого вскрытия, защищая ее от влаги и загрязнений, а также обеспечивая профессиональную упаковку, готовую к розничной продаже.

- Картонирование: Для завершения процесса блистерные упаковки передаются на автоматизированную картонажную машину. автоматизированные решения по картонированию эффективно упаковывают блистерные листы вместе с инструкциями для пациентов в готовые картонные коробки, которые затем запечатывают и маркируют для отслеживания партии.

Приобретая эти взаимосвязанные системы у одного надежного поставщика, такого как Grand, вы обеспечиваете механическую и электрическую совместимость, упрощаете управление проектами и создаете высокоэффективную, надежную и соответствующую стандартам производственную линию.

Главное преимущество: ваш знак качества

В фармацевтической отрасли нет места ошибкам. Каждая деталь способствует безопасности, эффективности и надёжности вашей продукции. машина для печати на капсулах и таблетках — это мощное заявление о вашей приверженности идеалам. Это инструмент, который защищает пациентов, укрепляет ваш бренд и оптимизирует вашу работу.

В Grand мы сочетаем передовые технологии с надежной конструкцией, соответствующей стандартам cGMP, создавая решения для печати, которые предлагают непревзойденное качество, универсальность и выгоду. Когда вы будете готовы проявить себя, наши специалисты помогут вам подобрать идеальное решение для ваших производственных нужд.