Глубокое погружение в современную картонажную машину

Ваш путеводитель по 11 лучшим производителям линий по производству инфузионных мешков в 2025 году

Корпус машины для наполнения порошком и производственной линии

Введение

В отраслях, где точность — не просто цель, а необходимость, — от производства жизненно важных фармацевтических препаратов до деликатесов, — обработка и упаковка порошков представляют собой уникальный набор задач. Контроль пыли, точное дозирование и сохранение целостности продукта — лишь некоторые из трудностей, с которыми ежедневно сталкиваются производители. Решение? Передовая технология. машина для наполнения порошком в центре бесшовно интегрированного линия по производству порошковой фасовки. Именно здесь инженерное совершенство отвечает производственным потребностям, и сегодня мы подробно разберем, что представляет собой конечный результат. оборудование для наполнения порошком, особое внимание уделив инновационным решениям, предлагаемым Grand.

Анатомия современной линии фасовки порошков

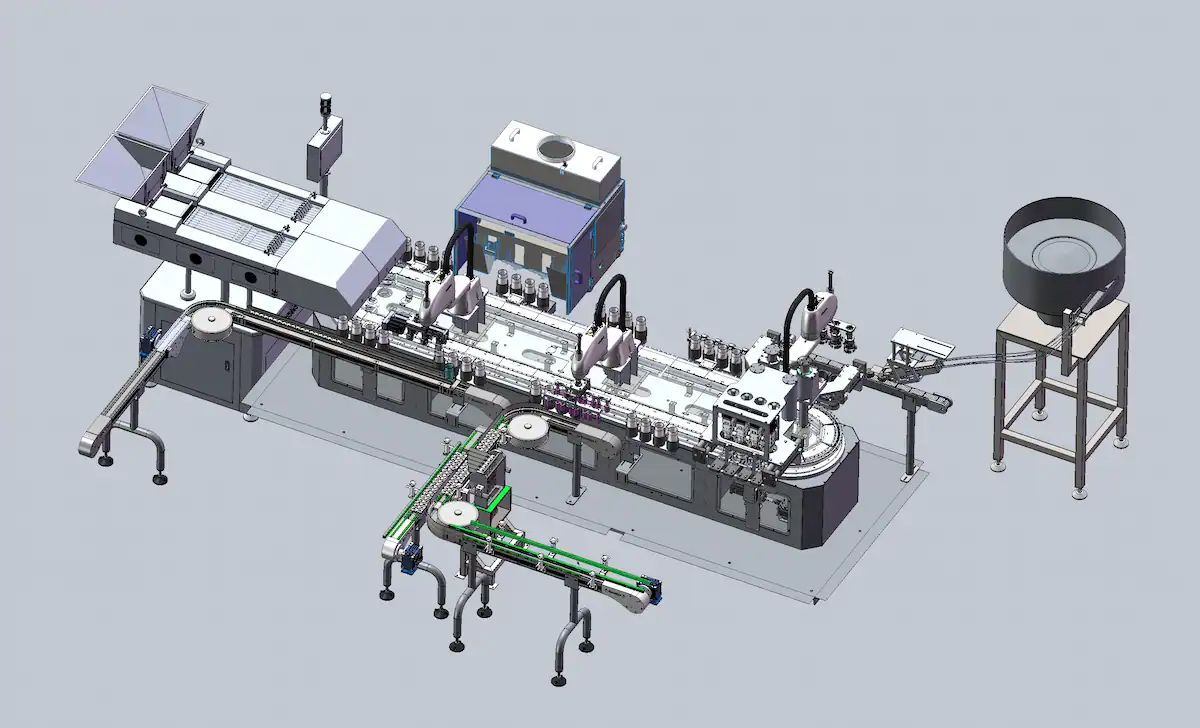

Современный линия по производству порошковой фасовки Это больше, чем просто один станок; это тщательно отлаженная система, где каждый компонент работает слаженно, обеспечивая идеальный конечный продукт. Давайте рассмотрим типичный технологический процесс такой линии на примере передовой системы Grand.

- Подготовка бутылки: Путешествие начинается с подготовки контейнеров. Это часто включает в себя линия розлива Система начинается с поворотного стола для подачи пустых бутылок в систему. Чтобы обеспечить безупречную среду для порошка, роботизированная система воздушной промывки с саморегулирующимся захватом очищает бутылки изнутри ионизированным воздухом, удаляя пыль и загрязнения.

- Интеллектуальная загрузка: После очистки бутылки точно помещаются на конвейерную систему. Этот важный этап выполняется загрузочным роботом SCARA, который также оснащён автоматически настраиваемым захватом для бутылок разных размеров, что обеспечивает бережную и точную передачу на следующий этап.

- Сердце линии: наполнение и дозирование: Бутылки заполняются точным количеством порошка с использованием высокотехнологичного оборудования. машина для наполнения порошком. Мы рассмотрим этот важнейший компонент более подробно позже.

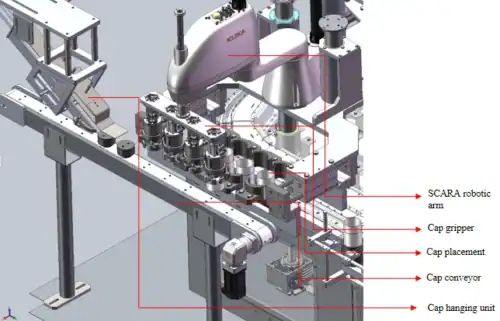

- Укупорка и герметизация: После наполнения бутылки надёжно укупориваются. Робот-упаковщик DELTA устанавливает крышки на бутылки, которые затем сортируются вибрационной чашей и затягиваются сервоуправляемой укупорочной машиной.

- Контроль качества и отбраковка: Для гарантии качества продукции линия оснащена системой отбраковки бракованной продукции. Бутылки, не соответствующие строгим стандартам качества, автоматически снимаются с линии и утилизируются.

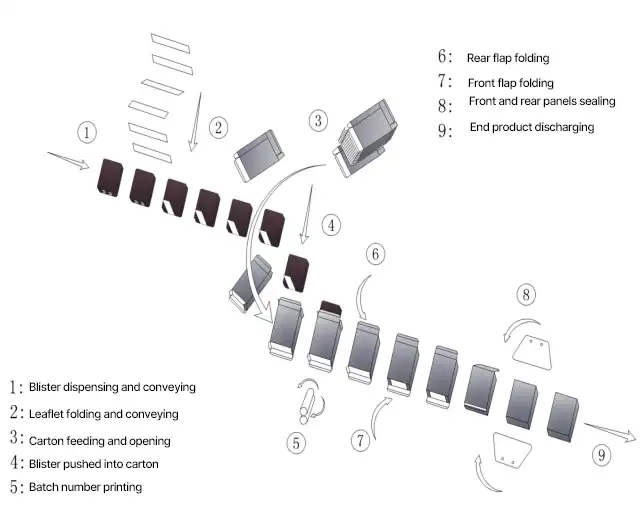

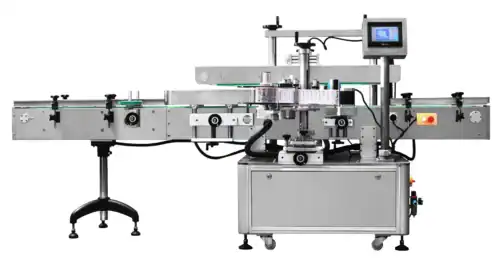

- Этикетирование и картонирование: Заключительные этапы включают наклеивание этикеток на бутылки с помощью высокоскоростная этикетировочная машина и затем упаковывают их в картонные коробки с помощью автоматической картонажной машины.

Весь этот процесс осуществляется с помощью сложной конвейерной системы, и, как мы увидим, Grand выводит ее на новый уровень благодаря своей инновационной технологии магнитной подвески.

Сердце линии: машина для фасовки порошка

Центральная часть любого линия по производству порошковой фасовки это, конечно, машина для наполнения порошком В мире порошковые наполнителиточность имеет решающее значение, особенно когда речь идет о микродозах дорогих или сильнодействующих веществ. ГрандРешение компании, дозирующая и взвешивающая машина для микродозирования порошков, является ярким примером передовых технологий

машина для фасовки сухого порошка технологии.

Вот что делает современный машина для наполнения порошком как Гранд такой исключительный:

- Непревзойденная точность: В машине используются высокоточные цифровые датчики ведущих производителей, таких как HBM или Toledo, обеспечивающие невероятно точное взвешивание со средней погрешностью всего ±0,1 г (в зависимости от характеристик материала). Такой уровень точности критически важен для эффективности, безопасности продукции и контроля затрат.

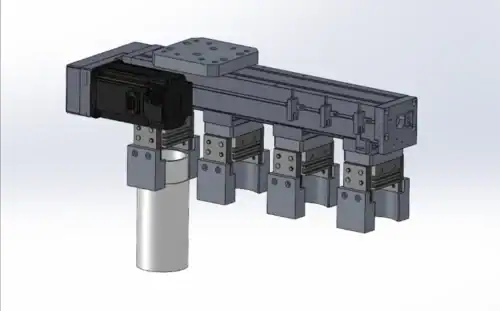

- Высокоскоростная производительность: Модульный линейный весовой дозатор APW-1B4(03) с четырьмя головками способен взвешивать от 10 до 40 мешков/мин, обеспечивая высокую производительность без ущерба для точности. Открытие и закрытие весового бункера управляется сервоприводом, что обеспечивает высокую скорость и точность взвешивания.

- Гибкость и универсальность: Модульная конструкция весов со сменными алюминиевыми картриджами позволяет легко адаптировать их к различным продуктам и производственным потребностям. Весы даже способны одновременно взвешивать различные материалы для смешанной упаковки.

- Удобное управление: Сенсорный экран диагональю 15,6 дюйма обеспечивает интуитивно понятное управление функциями аппарата. Система поддерживает несколько языков и обеспечивает многоуровневый контроль доступа для различных уровней полномочий пользователей.

- Интеллектуальные функции: Машина оснащена интеллектуальной системой оповещения о неисправностях, которая выдает четкие диагностические подсказки для быстрого выявления проблем и минимизации простоев. Операторы также могут изменять параметры в режиме реального времени во время работы.

Такие расширенные функции являются тем, что отличает современный автоматическая машина для наполнения порошком в отличие от своих предшественников, предлагая производителям беспрецедентный контроль и эффективность.

За пределами наполнения: сила автоматизации и робототехники

Для достижения настоящей эффективности и согласованности современные линии по производству порошковой фасовки В значительной степени опираются на автоматизацию и робототехнику. Система Гранда прекрасно это демонстрирует благодаря интеграции роботов KUKA на различных этапах процесса.

- Роботизированная воздушная промывка: Робот-манипулятор KUKA выполняет воздушную промывку бутылок, вращая шестую ось на 180 градусов для инвертированного удаления пыли. Этот автоматизированный процесс обеспечивает тщательную очистку и исключает риск человеческой ошибки.

- Роботизированная загрузка и укупорка: Роботы SCARA используются для загрузки бутылок на конвейер и установки крышек на бутылки. Эти роботы быстрые, точные и могут работать непрерывно, что значительно повышает скорость производства.

- Смена форматов без лишних хлопот: Ключевым преимуществом использования роботизированных рук является отсутствие необходимости в сменных деталях при смене формата. Это означает, что переход между разными размерами бутылок происходит быстро и легко, сокращая время простоя и повышая гибкость производства.

Использование робототехники в линия розлива не только повышает эффективность, но и создает более стерильную производственную среду, что особенно важно в фармацевтической и пищевой промышленности.

Революционное событие: система транспортировки на магнитной подвеске

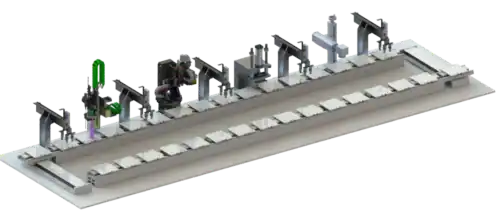

Возможно, самое новаторское нововведение в истории Гранда

линия по производству порошковой фасовки Это внедрение системы конвейерной магнитолевитации. Эта технология, использующая магнитную левитацию для перемещения продукции по линии, обладает множеством преимуществ по сравнению с традиционными ленточными или цепными конвейерами.

- Невероятная скорость и точность: Система магнитной подвески развивает скорость до 5 м/с с ускорением 5g и обеспечивает исключительную точность позиционирования ±50 мкм. Это обеспечивает быстрое и точное перемещение бутылок между станциями, что крайне важно для высокоскоростных перевозок.

- Непревзойденная гибкость: Двигатели на магнитолевитационной трассе управляются независимо друг от друга, что обеспечивает гибкие варианты компоновки, включая петлевые, стыковочные схемы в плоскости/вертикаль и расходящиеся компоновки. Эта адаптивность позволяет проектировать производственную линию, идеально соответствующую имеющемуся пространству и производственным требованиям.

- Низкие эксплуатационные расходы и совместимость с чистыми помещениями: Отсутствие трения в системе магнитной подвески означает отсутствие износа, что снижает затраты на техническое обслуживание и обеспечивает более тихую работу. Отсутствие движущихся частей также делает её идеальной для применения в чистых помещениях, поскольку она генерирует меньше частиц.

- Полная интеграция: Компания Grand полностью интегрировала систему магнитной подвески в свою производственную линию, обеспечив динамическую синхронизацию различных процессов, таких как укупорка и визуальный контроль. Такая интеграция способствует более эффективному управлению производством и контролю качества.

Внедрение технологии магнитной подвески является ярким показателем приверженности компании Grand к инновациям и предоставлению своим клиентам самых передовых решений. оборудование для наполнения порошком на рынке.

Обеспечение качества и соответствия от начала до конца

В любом производственном процессе контроль качества имеет первостепенное значение. линия по производству порошковой фасовки включает в себя ряд функций, гарантирующих, что каждый продукт, покидающий линию, соответствует самым высоким стандартам качества.

- Контрольное взвешивание в процессе производства: В систему магнитолевитационного конвейера интегрирован контрольный весовой контроль с независимыми датчиками веса, что позволяет в режиме реального времени проверять вес каждой бутылки.

- Автоматическое отклонение: Как уже упоминалось, система отбраковки бракованной продукции автоматически удаляет с линии любые несоответствующие требованиям изделия. Это предотвращает попадание бракованной продукции на рынок и защищает репутацию бренда.

- Проверка зрения: Интеграция систем визуального контроля еще больше усиливает контроль качества, позволяя обнаруживать косметические дефекты или другие проблемы, которые невозможно выявить только путем взвешивания.

Эти меры контроля качества в сочетании с общей точностью и надежностью линии гарантируют производителям возможность выпускать продукцию стабильно высокого качества.

Комплексное решение для ваших задач по упаковке порошков

Grand предлагает не просто отдельные машины, а комплексное, интегрированное решение для упаковки порошков, от первоначальной оценки продукта до послепродажного обслуживания и поддержки. Это включает в себя всё: от разработки и оптимизации бутылок до технической поддержки на месте и наличия запасных частей. Объединяя этикетировочную машину и автоматическую картонажную машину в единую модульную систему с магнитолевитационным конвейером, Grand помогает экономить пространство, снижать трудозатраты и оптимизировать весь производственный процесс.

Инвестирование в современные, автоматизированные машина для наполнения порошком Производственная линия больше не роскошь; это стратегическая необходимость для любой компании, стремящейся конкурировать на современном быстро меняющемся рынке. Существуют технологии, позволяющие решить проблемы, связанные с фасовкой порошков, и такие компании, как Grand, лидируют, предлагая инновационные решения, обеспечивающие точность, эффективность и надежность в любой ситуации. Хотя первоначальные инвестиции в такую передовую технологию могут показаться значительными, долгосрочные преимущества в виде повышения производительности, сокращения отходов и улучшения качества продукции делают её разумным выбором для любого дальновидного производителя.

В заключение статьи: если вашей компании необходимо повысить эффективность производства, Grand — определённо лучший выбор. Вы можете связаться с нами по электронной почте, указанной внизу, или отправить запрос справа.