Что можно упаковать с помощью машины для розлива пероральных жидкостей?

В чем заключается принцип грануляции порошка в псевдоожиженном слое?

Тубонаполнительная машина NF-150: глубокое погружение в технологию двойного назначения

Введение

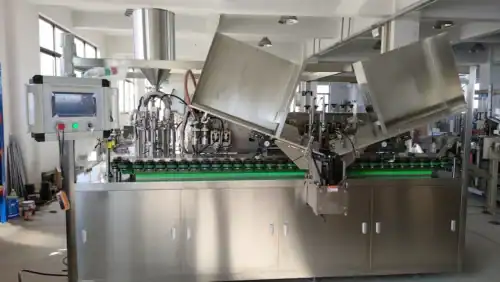

В условиях конкуренции в косметическом, фармацевтическом и химическом производстве эффективность определяется не только скоростью, но и точностью, надёжностью и универсальностью. Производственные менеджеры постоянно ищут оборудование, способное минимизировать время простоя, уменьшить количество отходов и адаптироваться к различным требованиям к упаковке. Задача — найти машину, которая будет превосходна во всех этих областях. Встречайте NF-150, полностью автоматический машина для наполнения туб разработано как комплексное решение для современных производственных линий.

Независимо от того, упаковываете ли вы высоковязкие мази, гели, кремы или даже зубную пасту, NF-150 предлагает мощное сочетание передовых технологий и надёжной конструкции. В этой статье мы подробно рассмотрим особенности, которые делают NF-150 таким выдающимся инструментом, рассмотрим его передовую механику, возможности точного наполнения и укупорки, а также революционную систему двойного назначения для пластиковых и алюминиевых туб.

Что такое Тубонаполнительная машина NF-150?

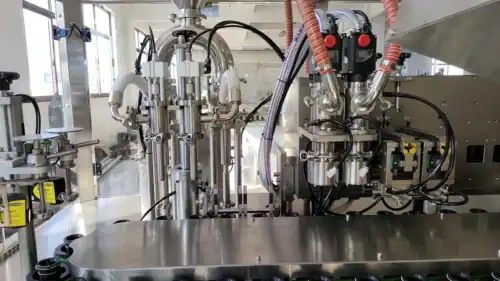

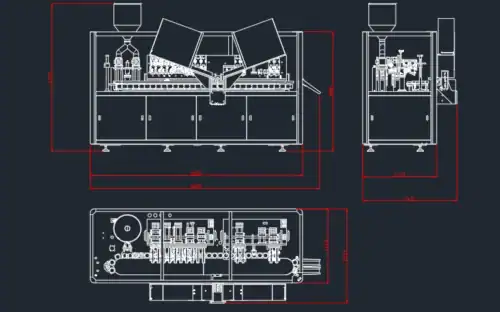

NF-150 — это современный, полностью закрытый аппарат для розлива и укупорки из нержавеющей стали. Он является примером инновационного проектирования, разработанного путем интеграции передовых международных разработок с практическими реалиями отечественного производства туб. Этот аппарат специально разработан для работы с широким спектром типов туб, включая все типы пластиковых туб, композитных туб из алюминия и пластика и традиционные алюминиевые тубы.

Ключевые показатели эффективности:

- Максимальная скорость: 130 пробирок в минуту

- Стабильная скорость производства: 100-120 пробирок в минуту

- Точность заполнения: ±1%

По своей сути NF-150 представляет собой двухстанционную машину, которая автоматизирует весь процесс от загрузки тубы до герметизации и выталкивания, что делает ее идеальным выбором для крупносерийного производства.

Основа инноваций: передовая механика и система привода

Долговечность любого промышленного оборудования зависит от качества его основных механизмов. NF-150 использует комплекс передовых технологий, обеспечивающих не только высокую скорость, но и исключительную стабильность и долговечность.

Точность сервопривода для плавной работы

В отличие от традиционных механических систем, NF-150 использует усовершенствованный сервоприводной поворотный стол и уникальную систему главного привода. Вся машина приводится в движение в общей сложности девять отдельных серводвигателей, контролируя критические действия, включая:

- Выравнивание цветовой метки

- Объем наполнения

- Главный приводной двигатель

- Подъем/опускание сопла

- Вращение поворотного стола

- Алюминиевая трубка складная

- Термосварка пластиковых трубок

Широкое использование серводвигателей, координируемых сложным контроллером движения, гарантирует плавность, мягкость и идеальную синхронизацию каждого движения. Это устраняет рывки, характерные для старых машин, что снижает механическую нагрузку и значительно повышает надёжность машины на высоких скоростях.

Создано для долговечности и соответствия требованиям GMP

Чтобы обеспечить исключительный срок службы, главный кулачок изготовлен из кованой стали, что делает его чрезвычайно устойчивым к износу даже при непрерывной работе на высоких скоростях.

Двойная система отопления Swiss Leister (с системой контроля температуры)

Кроме того, NF-150 разработан с учётом потребностей фармацевтической промышленности. Как ведущий машина для наполнения фармацевтических туб, он соответствует строгим требованиям GMP. Рабочая поверхность над столешницей оснащена износостойкими подшипниками скольжения, не требующими смазки, что значительно снижает риск загрязнения продукта. Полностью закрытый корпус из нержавеющей стали не только долговечен, но и прост в очистке и обслуживании.

Мастер-класс по наполнению и герметизации

Технологический процесс NF-150 представляет собой тщательно спроектированную последовательность, рассчитанную на максимальную точность и эффективность.

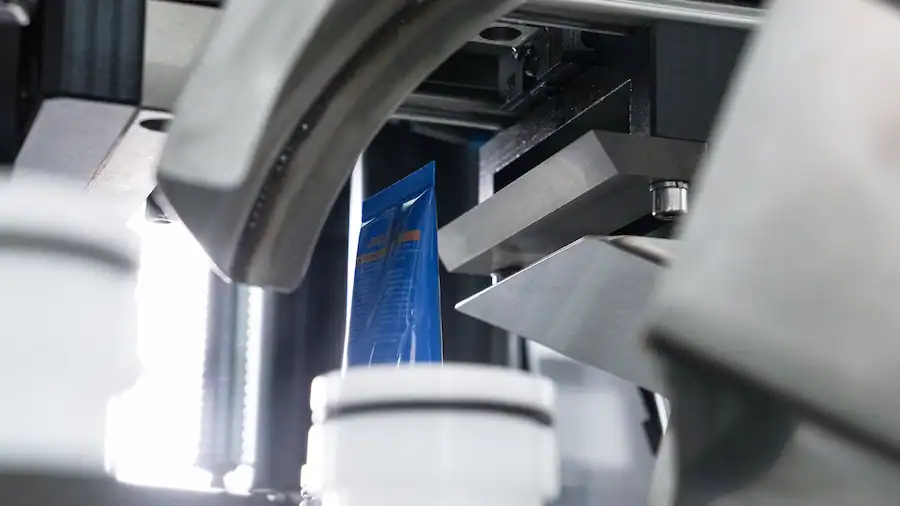

Высокопроизводительное, бережное зондовое питание

Инжекционную форсунку можно поднимать и опускать, а высоту трубы можно свободно регулировать.

Процесс начинается с автоматизированной системы подачи пробирок. Магазин большой ёмкости вмещает более 1500 пробирок (например, 20-граммовую пробирку), что сводит к минимуму необходимость частого вмешательства оператора. Сервоприводной механизм плавно и аккуратно подаёт пробирки на поворотную пластину. Эта пластина оснащена отверстиями для создания отрицательного давления, которые надёжно удерживают каждую пробирку за счёт вакуума, обеспечивая её идеальное попадание в чашку. Операторы могут даже управлять процессом подачи пробирок с помощью кулисного переключателя во время работы машины.

Механизм точного наполнения

Сердцем машины является поршневая система розлива с клапанным корпусом. NF-150 оснащен несколькими интеллектуальными функциями, гарантирующими идеальную заправку:

- Технология предотвращения капель и застревания: Чтобы решить распространённые проблемы с пузырьками, разбрызгиванием и засорами насадки, наполнительная насадка опускается до дна тубы перед началом наполнения. Затем она медленно поднимается по мере выдачи продукта. После завершения наполнения насадка на мгновение останавливается и выполняет «сдув», используя струю воздуха для полного отделения продукта от насадки. Это обеспечивает чистоту насадки и предотвращает образование тяжей и капель продукта.

- Двойная гарантия «Нет трубки, нет наполнения»: Машина оснащена двумя независимыми системами контроля «нет тюбика — нет наполнения». Этот механизм двойной проверки гарантирует, что машина не выдаст ценный продукт, если чаша с тюбиком пуста, что исключает отходы и грязную уборку.

- Быстросменные насадки: Соединение между насадкой и соплом осуществляется с помощью быстросъемного соединения. Такая конструкция гарантирует отсутствие остатков пасты в соединении и делает разборку для очистки невероятно быстрой и простой.

Эта система способна обрабатывать широкий диапазон объемов: от 3 до 250 мл для пластиковых пробирок и от 3 до 150 мл для алюминиевых пробирок, что делает ее идеальным решением для работы с любыми объемами: от образцов до готовых розничных продуктов.

Безупречная технология герметизации: пластик и алюминий

Как всеобъемлющий машина для запайки трубNF-150 предлагает специальные высоконадежные методы герметизации для различных материалов.

- Для пластиковых и композитных алюминиево-пластиковых труб применяется метод сварки горячим воздухом. Этот метод обеспечивает прочное, чистое и эстетичное соединение, что делает его исключительно эффективным. герметик для пластиковых труб.

- Для алюминиевых туб машина использует прочную механическую систему фальцовки. Роботизированный манипулятор выполняет серию точных фальцовок, создавая надёжный многослойный обжимной шов.

После запечатывания машина выполняет кодирование даты/партии и обрезку хвостовой части, после чего автоматически выбрасывает готовую тубу.

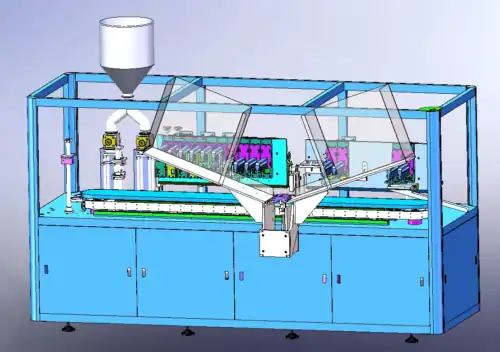

Непревзойденное преимущество двойного назначения: одна машина, два материала

Возможно, самым значительным нововведением NF-150 является его конструкция «одна машина, два применения». Рабочая платформа машины одновременно оснащена механизмами для оба герметизация пластика горячим воздухом и механическая фальцовка алюминия.

Это означает, что если вам нужно переключить производство с машина для наполнения пластиковых туб к машина для наполнения алюминиевых тубВам не нужно выполнять сложную и трудоёмкую разборку и замену механических частей. Оператор может выбрать желаемый режим работы. Эта революционная функция:

- Значительно сокращается время переналадки.

- Минимизирует трудозатраты.

- Избегает риска механических неисправностей которые могут возникнуть при многократной сборке и разборке.

- Увеличивает время безотказной работы машины и эксплуатационную гибкость.

Интеллектуальное управление, безопасность и синергия производственной линии

NF-150 оснащён комплексной электрической системой Siemens, обеспечивающей стабильность и надёжность мирового класса. В нём используются пневматические компоненты AirTAC и датчики Banner (США). Интерфейс «человек-машина» (HMI) представляет собой удобный сенсорный экран, обеспечивающий простоту управления и мониторинга.

Безопасность имеет первостепенное значение, поэтому машина оснащена несколькими защитными устройствами:

- Защита главного сервопривода от перегрузки.

- Защита переключения ручного/автоматического режима работы.

- Защита от низкого давления воздуха.

- Легкодоступный аварийный выключатель.

Наконец, NF-150 создан для командной работы. Его можно использовать как отдельное устройство или легко интегрировать в систему. Автоматическая картонажная машина Grand и а Автоматическая термоусадочная машина Grand создать полностью автоматизированную, сквозную производственную линию.

Заключение

Полностью автоматическая машина для розлива и запечатывания NF-150 — это больше, чем просто оборудование; это стратегический актив для любого современного производственного предприятия. Сочетая в себе высокую скорость, исключительную точность, конструкцию, соответствующую стандартам GMP, и революционную гибкость системы двойного назначения, она решает основные задачи современного производства. Для компаний, стремящихся к масштабированию своего производства. Наполнение зубной пасты или Машина для фасовки мазей В любых операциях или любых приложениях, требующих универсальной и надежной упаковки труб, NF-150 предлагает надежное, эффективное и перспективное решение.

Часто задаваемые вопросы (FAQ)

1. Каким образом NF-150 обрабатывает как алюминиевые, так и пластиковые трубы без существенной переналадки?

Ключевое новшество NF-150 заключается в том, что механизмы герметизации для обоих типов материалов — система горячего воздуха для пластиковых/композитных труб и механическая система фальцовки для алюминиевых труб — расположены на рабочей платформе машины. Оператор может выбрать нужную систему через интерфейс управления, не снимая, не заменяя и не перенастраивая тяжёлые механические детали. Это сокращает время переналадки с нескольких часов до нескольких минут и значительно повышает эксплуатационную гибкость.

2. Какие особенности предотвращают стекание и налипание отходов продукта на насадку?

Машина использует многоступенчатый процесс наполнения «выдувом». Сначала наполнительная насадка опускается глубоко в тубу, чтобы предотвратить разбрызгивание. По мере наполнения она поднимается. После завершения наполнения насадка на короткое время останавливается, и струя воздуха аккуратно «разрезает» поток продукта. Это гарантирует отсутствие остатков продукта на кончике насадки и капаний, что крайне важно для поддержания чистоты и предотвращения потерь ценного продукта.

3. Подходит ли NF-150 для чистых помещений или фармацевтических предприятий?

Да, конечно. Он разработан с учётом стандартов GMP (надлежащей производственной практики). Машина имеет полностью закрытый корпус из нержавеющей стали, который легко стерилизовать. Важно отметить, что подвижные части на рабочей поверхности оснащены специальными износостойкими подшипниками скольжения, не требующими смазки маслом, что исключает основной потенциальный источник загрязнения и делает её идеальным решением. машина для наполнения фармацевтических туб.

4. Каким образом машина обеспечивает точность ±1% при скорости до 120 трубок в минуту?

Точность достигается благодаря усовершенствованной системе привода и управления. Насос для розлива управляется специальным серводвигателем, а не механическим кулачком. Это обеспечивает исключительно точное программное управление длиной хода и скоростью поршня. Эта цифровая точность в сочетании со стабильной работой сервопривода основного поворотного стола без вибраций гарантирует постоянство и точность каждой заливки даже при максимальной скорости производства.

5. Что произойдёт, если в стаканчике не будет трубочки? Будет ли кофемашина продолжать выдавать продукт?

Нет, не соответствует. NF-150 оснащён двумя отдельными и независимыми системами датчиков «нет трубки — нет наполнения». Если первый датчик не обнаруживает трубку в стакане, второй датчик срабатывает как предохранитель. Если оба датчика подтверждают отсутствие трубки, система управления автомата не активирует последовательность наполнения для данной станции. Эта система двойной проверки обеспечивает надёжную защиту от потерь продукта и загрязнения аппарата.