Полное руководство: решения для защиты и блистерной упаковки | GrandPack

Полное руководство по технологии смешивания сухих порошков | GrandPack

Применение линии по производству лиофилизированного порошка вакцины

Будущее вакцин: как лиофилизированный порошок меняет стабильность и доступность

Пандемия COVID-19 вывела науку о вакцинах на передний план глобального обсуждения. Мы стали свидетелями невероятной скорости, с которой новые технологии, такие как вакцины мРНК, могли разрабатываться для борьбы с глобальной угрозой. Однако этот триумф также выявил критически важную слабость нашей глобальной инфраструктуры здравоохранения: холодовую цепь. Логистическая проблема транспортировки и хранения вакцин при сверхнизких температурах (таких как -70°С)[1]создали огромные препятствия, особенно в отдаленных и развивающихся регионах. Но что, если бы мы могли устранить эту температурную зависимость? Что, если бы самые передовые вакцины в мире могли храниться при комнатной температуре в течение месяцев, не теряя своей силы? Это не научная фантастика; это реальность, которая стала возможной благодаря лиофилизированный порошок, революционная формула, призванная кардинально изменить подход к доступности вакцин для всех и везде.

Загадка холодовой цепи: дорогостоящая и хрупкая система

Прежде чем углубляться в решение, важно понять проблему. «Холодовая цепь» — это цепочка поставок с контролируемой температурой. Для многих вакцин, спасающих жизни, это означает непрерывную серию охлажденных или замороженных единиц хранения и транспортировки, от завода-изготовителя до руки пациента.

Эта система сопряжена с рядом проблем:

- Экстремальная стоимость: Создание и поддержание надежной холодильной цепи требует значительных инвестиций в специализированные морозильные камеры, рефрижераторы и контрольно-измерительное оборудование.

- Логистическая сложность: Любой разрыв в цепочке — отключение электроэнергии, отказ оборудования или человеческая ошибка — может сделать всю партию вакцин бесполезной. Этот риск увеличивается в регионах с ненадежным электроснабжением или сложным рельефом.

- Ограниченный охват: Зависимость от постоянного электроснабжения по своей сути ограничивает распространение вакцины, часто оставляя позади сельские и малообеспеченные общины. Те самые группы населения, которые часто наиболее уязвимы, становятся наиболее труднодоступными.

Эти ограничения были ярко подчеркнуты при первоначальном развертывании вакцин мРНК от COVID-19. Несмотря на революционность своей эффективности, их строгие требования к хранению означали, что доступ к ним на какое-то время был привилегией географии и инфраструктуры. Это критическая проблема, над решением которой неустанно трудятся фармацевтические новаторы.

Знакомьтесь с технологией сублимационной сушки: наука о стабильности

Элегантным решением проблемы холодовой цепи является процесс, который совершенствовался десятилетиями: лиофилизация, или сублимационная сушка. Технология сублимационной сушки это щадящий процесс дегидратации, который удаляет воду из продукта, не повреждая его тонкую молекулярную структуру, что имеет решающее значение для чувствительных биологических продуктов, таких как вакцины.

Процесс можно разбить на три основных этапа:

- Замораживание: Жидкая вакцина, находящаяся во флаконах, осторожно охлаждается до температуры значительно ниже точки замерзания (например, -40°C). Этот шаг должен точно контролироваться, чтобы обеспечить образование соответствующих кристаллов льда, что является ключом к успешному процессу сушки.

- Первичная сушка (сублимация): После заморозки флаконы помещаются в глубокий вакуум. Затем температура медленно повышается. В условиях низкого давления замороженная вода не тает в жидкость; вместо этого она напрямую превращается в пар — процесс, называемый сублимацией. Это удаляет большую часть воды из продукта без разрушительных сил испарения жидкой фазы.

- Вторичная сушка (десорбция): После того, как лед исчез, некоторые молекулы воды остаются связанными с поверхностью компонентов вакцины. Температура повышается еще больше (все еще под вакуумом), чтобы осторожно удалить эти последние следы влаги, в результате чего получается сухой, стабильный торт лиофилизированный порошок с остаточной влажностью менее 2%.

Конечный продукт, а лиофилизированный порошок во флаконе, легкий, удобный для транспортировки и, что самое важное, удивительно стабильный в широком диапазоне температур. Непосредственно перед введением медицинский работник может восстановить его, просто добавив стерильную воду, и вернуть его в жидкую, пригодную для инъекций форму за считанные секунды.

Знаменательный прорыв: появление термостабильных лиофилизированных вакцин

Теоретические преимущества сублимационной сушки очевидны, но недавнее исследование предоставило весомые реальные доказательства ее преобразующего потенциала, особенно для самых передовых вакцин мРНК. Научная работа, опубликованная в Открытие клеток Подробности разработки SARS-CoV-2[2]лиофилизированный порошок вакцина, демонстрирующая невероятную долгосрочную стабильность и мощную иммуногенность.

Это исследование было не просто доказательством концепции; это была всесторонняя демонстрация успеха от лабораторного стола до испытаний на людях. Вот основные выводы:

- Беспрецедентная термическая стабильность: Исследователи разработали оптимизированную технологию сублимационной сушки, которая сохранила целостность вакцины. В результате лиофилизированный порошок не показал существенных изменений в своих физических или химических свойствах после хранения в течение 6 месяцев при 25°C (77°F). Он даже сохранил высокую целостность после 60 дней при экстремальной температуре 40°C (104°F). Это полностью разрушает барьер сверххолодного хранения.

- Мощная и сохраняющаяся биологическая активность: Стабильность бессмысленна, если вакцина не работает. Исследование подтвердило, что процесс сублимационной сушки не нанес вреда эффективности вакцины. В исследованиях на животных с участием мышей, кроликов и макак-резусов восстановленная сублимационная вакцина вызывала мощные и крепкие иммунные реакции, сопоставимые с ее свежеприготовленным жидким аналогом.

- Успех испытаний на людях: Самое впечатляющее, что вакцина была испытана в качестве бустера на добровольцах. После получения двух доз обычной инактивированной вакцины, один бустер LyomRNA-Omicron лиофилизированная вакцина повышенный уровень нейтрализующих антител против вариантов Омикрона по крайней мере в 253 разаЭто невероятное повышение иммунитета было достигнуто лишь с незначительными побочными эффектами, и не было зарегистрировано ни одного серьезного неблагоприятного события.

Это исследование эффективно обеспечивает проект нового поколения Лиофилизированные вакцины. Это доказывает, что мы можем получить лучшее из обоих миров: скорость и точность технологии мРНК в сочетании со стабильностью и доступностью лиофилизированной формулы.

От лаборатории до флакона: решающая роль линии по производству лиофилизированных порошков

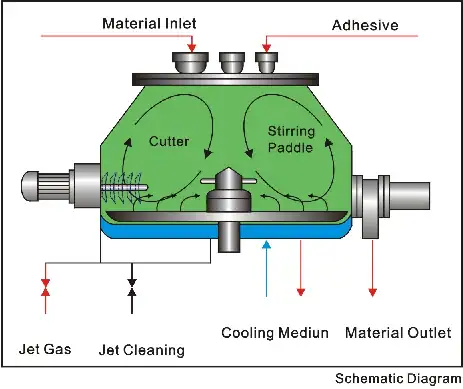

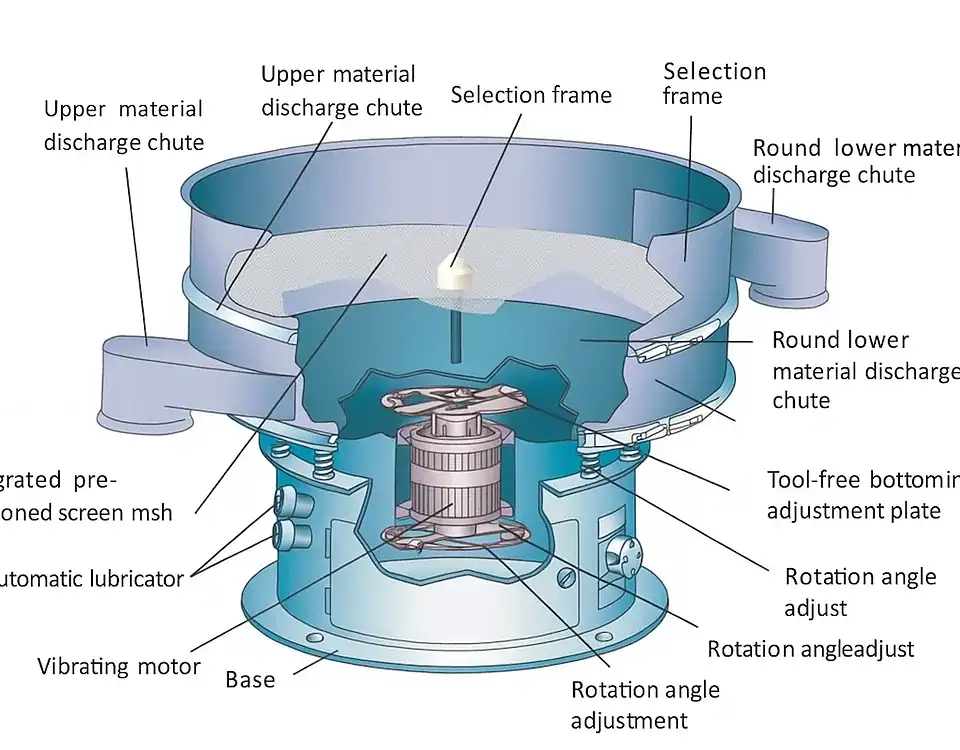

Создание стабильной лиофилизированный порошок одно дело; производство сотен миллионов доз надежно, безопасно и эффективно — другое. Для этого требуется сложная, интегрированная Линия по производству сублимированного порошка. Это не отдельная машина, а целостная система, где каждый шаг тщательно контролируется для обеспечения качества и стерильности конечного продукта.

Современное Линия по производству флаконов лиофилизированного порошка Процесс включает в себя несколько важнейших этапов:

- Промывка и депирогенизация флаконов: Процесс начинается с очистки стеклянных флаконов от любых твердых частиц, а затем их пропускают через высокотемпературный туннель для уничтожения пирогенов (веществ, вызывающих лихорадку).

- Асептическое наполнение: В условиях высокой стерильности точная доза жидкой вакцины помещается в каждый флакон.

- Полуостановка: Специальная пробка устанавливается на флакон, но не полностью. Это позволяет водяному пару выходить во время процесса сублимационной сушки, сохраняя стерильность.

- Автоматическая загрузка и лиофилизация: Лотки с полузакрытыми флаконами автоматически загружаются в сублимационную сушилку. Многоступенчатый цикл лиофилизации, который может длиться несколько дней, выполняется с точностью, контролируемой компьютером.

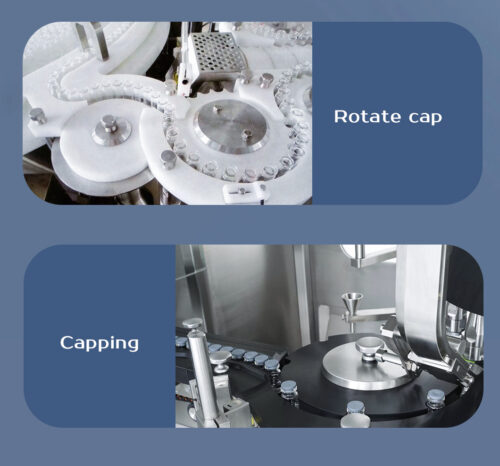

- Полное закупоривание и укупоривание: После завершения цикла сушки полки внутри сублимационной сушилки нажимают вниз, полностью устанавливая пробки во флаконы под вакуумом. Затем флаконы передаются в укупорочную машину, где на них надевается алюминиевая пломба, что обеспечивает герметичность и защиту от несанкционированного доступа.

Каждый из этих шагов должен соответствовать строгим стандартам надлежащей производственной практики (GMP). Интеграция и автоматизация современного Линия по производству флаконов имеют первостепенное значение для минимизации вмешательства человека, снижения риска заражения и обеспечения постоянства дозы.

Видение GrandPack: проектирование будущего производства вакцин

В ГрандПак, мы понимаем, что прорывная наука требует прорывной инженерии. Обещание стабильного, глобально доступного Лиофилизированные вакцины может быть реализовано только с помощью производственной технологии, которая столь же продвинута. Линия по производству лиофилизированного порошка GrandPack разработан с нуля для удовлетворения строгих требований современного биологического производства.

Наши интегрированные решения обеспечивают точность, стерильность и масштабируемость, необходимые фармацевтическим компаниям для внедрения этих терапий нового поколения в мир. Разрабатывая надежные и автоматизированные системы для всего, от мытья флаконов до окончательной укупорки, мы даем нашим партнерам возможность производить лиофилизированный порошок во флаконе с максимальной уверенностью и эффективностью. Мы не просто строим машины; мы строим инфраструктуру для более здорового будущего, гарантируя, что следующая вакцина, спасающая жизни, может достичь каждого человека, который в ней нуждается, независимо от того, где он живет.

Путь от сложной жидкости к стабильной лиофилизированный порошок это чудо науки и техники. Это ключ к открытию истинного равенства вакцин и укреплению нашей защиты от будущих пандемий.

Часто задаваемые вопросы (FAQ)

1. Каковы основные компоненты линии по производству сублимированных порошков GrandPack? Полный Линия по производству лиофилизированного порошка GrandPack представляет собой интегрированную систему, которая обычно включает ультразвуковую моечную машину для флаконов, туннель депирогенизации с циркуляцией горячего воздуха, машину для асептического наполнения и полуукупорки флаконов, сублимационную сушилку (лиофилизатор) с автоматическими системами загрузки и выгрузки и машину для укупорки флаконов. Эти компоненты работают в бесшовной координации для перемещения флаконов от очистки до конечного, запечатанного продукта в стерильной среде.

2. Каким образом производственная линия обеспечивает стерильность лиофилизированного порошка во флаконе? Стерильность имеет первостепенное значение. Наши производственные линии обеспечивают это с помощью нескольких механизмов. Во-первых, весь процесс, от наполнения до укупорки, происходит в контролируемой асептической среде (часто с использованием технологии RABS или изолятора) для предотвращения микробного загрязнения. Флаконы стерилизуются и депирогенизируются при высоких температурах перед наполнением. Сам процесс лиофилизации, происходящий в герметичной вакуумной камере, по своей сути является асептическим. Наконец, флаконы автоматически закупориваются внутри камеры перед тем, как подвергаются воздействию внешней среды, что гарантирует целостность лиофилизированный порошок во флаконе.

3. Может ли производственная линия GrandPack работать с различными размерами флаконов и типами вакцин? Да, гибкость — это основной принцип дизайна. Линия по производству флаконов GrandPack лиофилизированный порошок Система спроектирована так, чтобы быть адаптивной. Она может быть сконфигурирована со сменными частями для обработки широкого диапазона стандартных размеров флаконов, от 2 мл до 100 мл. Системы управления как для разливочных машин, так и для сублимационных сушилок позволяют программировать специальные «рецепты», адаптированные к уникальным требованиям к объему, концентрации и формуле различных вакцин и биофармацевтических продуктов.

4. Что делает сублимационную сушку лучше других методов сушки вакцин? Хотя существуют и другие методы, такие как распылительная сушка, сублимационная сушка или лиофилизация лучше всего подходят для сложных, чувствительных к теплу биопрепаратов, таких как вакцины, по одной ключевой причине: она избегает жидкой фазы. Превращая лед непосредственно в пар (сублимация), она обходит поверхностное натяжение и тепло традиционного испарения, которые могут денатурировать белки и разрушать тонкие структуры мРНК-липидных наночастиц. Этот щадящий процесс гарантирует сохранение эффективности и структуры вакцины, что делает ее золотым стандартом для создания стабильных и эффективных Лиофилизированные вакцины.

Ссылки:

[1].Ай, Л., Ли, Ю., Чжоу, Л. и др. Лиофилизированные вакцины на основе мРНК-липидных наночастиц с долговременной стабильностью и высокой антигенностью против SARS-CoV-2. Cell Discov 9, 9 (2023). https://doi.org/10.1038/s41421-022-00517-9

[2].Гранадос-Риверон, Дж. Т. и Акино-Харкин, Г. Разработка современных вакцин мРНК-ЛНП с модифицированными нуклеозидами против SARS-CoV-2. Биомед. Фармакотер. 142, 111953 (2021).