คู่มือฉบับสมบูรณ์เกี่ยวกับเทคโนโลยีเครื่องผสมผงแห้ง | GrandPack

แท็บเล็ตยุคใหม่: การเคลือบฟิล์มเทียบกับการเคลือบน้ำตาลด้วยเครื่องเคลือบในปัจจุบัน

บรรจุภัณฑ์แบบ Alu Alu เทียบกับบรรจุภัณฑ์แบบพุพอง: การเลือกวัสดุกั้นที่ดีที่สุดสำหรับผลิตภัณฑ์ของคุณ

การแนะนำ

ในอุตสาหกรรมยา บรรจุภัณฑ์เป็นมากกว่าแค่ภาชนะธรรมดา บรรจุภัณฑ์เป็นส่วนประกอบสำคัญของการขนส่งยา เป็นแนวป้องกันด่านแรกที่รักษาความสมบูรณ์ ความปลอดภัย และประสิทธิภาพของผลิตภัณฑ์จากโรงงานไปยังผู้ป่วย เมื่อต้องเลือกบรรจุภัณฑ์ที่เหมาะสม คำศัพท์สองคำจะเข้ามามีบทบาทสำคัญอย่างหลีกเลี่ยงไม่ได้ในการสนทนา: อาลู อาลู และ แผลพุพอง บรรจุภัณฑ์ แม้ว่าจะดูคล้ายกัน แต่ความแตกต่างระหว่างบรรจุภัณฑ์ทั้งสองนั้นมีความสำคัญ เนื่องจากแสดงถึงระดับการปกป้องที่แตกต่างกันสำหรับความต้องการผลิตภัณฑ์ที่แตกต่างกัน การทำความเข้าใจความแตกต่างนี้ถือเป็นกุญแจสำคัญในการทำให้มั่นใจว่าผลิตภัณฑ์ของคุณยังคงเสถียร ปลอดภัย และมีประสิทธิภาพ

ในฐานะผู้นำในการให้บริการโซลูชันบรรจุภัณฑ์ขั้นสูง GrandPack รู้ดีว่าการเลือกใช้มาตรฐาน แผลพุพอง แพ็คและการป้องกันสูง ตุ่มอะลูอะลู สามารถกำหนดอายุการเก็บรักษาของผลิตภัณฑ์และความสามารถในการทำตลาดทั่วโลกได้ คู่มือที่ครอบคลุมนี้จะแนะนำคุณเกี่ยวกับความแตกต่างของประเภทบรรจุภัณฑ์แต่ละประเภท เปรียบเทียบคุณลักษณะของแต่ละประเภท และสำรวจเครื่องจักรที่ซับซ้อนซึ่งจำเป็นในการผลิต เพื่อช่วยให้คุณตัดสินใจเลือกผลิตภัณฑ์ยาได้อย่างถูกต้องที่สุด

มูลนิธิ: Standard Blister Packaging คืออะไร?

ก่อนที่จะเจาะลึกถึงรายละเอียดของ Alu Alu สิ่งสำคัญคือต้องทำความเข้าใจพื้นฐานก่อน: บรรจุภัณฑ์แบบพุพองมาตรฐาน นี่คือบรรจุภัณฑ์ยาที่พบได้ทั่วไปที่สุดบนชั้นวางยา บรรจุภัณฑ์แบบพุพองฟอยล์ โซลูชันนี้ประกอบด้วยส่วนประกอบหลักสองประการ:

- การสร้างภาพยนตร์: นี่คือแผ่นพลาสติกใสที่สามารถขึ้นรูปด้วยความร้อน โดยทั่วไปทำจาก พีวีซี (โพลีไวนิลคลอไรด์) หรือบางครั้งเสริมด้วยชั้นของ PVDC (โพลีไวนิลิดีนคลอไรด์) หรือวัสดุอื่น ๆ เพื่อเพิ่มชั้นป้องกันความชื้น แผ่นนี้จะถูกทำให้ร้อนแล้วขึ้นรูปโดยใช้แม่พิมพ์เพื่อสร้าง "ตุ่มพอง" หรือโพรงที่จะใส่เม็ดยาหรือแคปซูลแต่ละเม็ด

- แผ่นฟอยล์ปิดฝา: หลังจากวางผลิตภัณฑ์ไว้ในโพรงแล้ว จะมีแผ่นอลูมิเนียมฟอยล์ชุบแข็งบางๆ ที่เรียกว่า ฟอยล์ปิดฝาเภสัชปิดผนึกไว้ด้านบน ซึ่งเป็นส่วนที่ผู้บริโภคดันแท็บเล็ตผ่านเข้าไป

การรวมกันนี้จะสร้างแพ็คเกจขนาดยาที่ปลอดภัยและเฉพาะบุคคลซึ่งมอบผลประโยชน์ต่างๆ มากมาย:

- การมองเห็นผลิตภัณฑ์: พลาสติกใสช่วยให้ผู้ป่วยและเจ้าหน้าที่ทางการแพทย์ตรวจสอบผลิตภัณฑ์ได้โดยไม่ต้องเปิดบรรจุภัณฑ์ ทำให้มั่นใจได้ว่าจะได้รับยาที่ถูกต้อง

- การควบคุมปริมาณยา: แต่ละโดสจะถูกแยกออกจากกันเพื่อให้ผู้ป่วยสามารถติดตามการรับประทานยาและปฏิบัติตามแผนการรับประทานยาที่กำหนดไว้ได้ง่าย

- หลักฐานการงัดแงะ: จะต้องทำลายซีลอย่างถาวรจึงจะเข้าถึงผลิตภัณฑ์ได้ โดยต้องเป็นตัวบ่งชี้ที่ชัดเจนถึงการดัดแปลงที่อาจเกิดขึ้น

- การป้องกันที่ดี: ช่วยปกป้องความชื้นและก๊าซได้เป็นอย่างดี เหมาะสำหรับยาหลากหลายชนิดที่ไม่ไวต่อปัจจัยแวดล้อมมากนัก

รูปแบบพุพองมาตรฐานนี้คุ้มต้นทุนและอเนกประสงค์มาก ทำให้เป็นกำลังสำคัญของอุตสาหกรรมบรรจุภัณฑ์ยา ผลิตตามมาตรฐาน เครื่องบรรจุพุพอง เส้นจะผ่านกระบวนการที่เรียกว่า เทอร์โมฟอร์มมิ่ง

ป้อมปราการขั้นสูงสุด: บรรจุภัณฑ์แบบพอง Alu Alu คืออะไร?

ตอนนี้เรามาแนะนำทางเลือกประสิทธิภาพสูงกัน อาลู อาลู บรรจุภัณฑ์ที่เรียกอีกอย่างว่าบรรจุภัณฑ์แบบพุพอง Cold Form Foil (CFF) ถือเป็นผลิตภัณฑ์ป้องกันสูงสุดในโลกของเภสัชกรรม ตามชื่อ บรรจุภัณฑ์นี้ทำจากแผ่นลามิเนตอะลูมิเนียมทั้งหมด ทำให้มีความทึบแสงและกันน้ำได้อย่างสมบูรณ์ ตุ่มโลหะ.

หนึ่ง ตุ่มอะลูอะลู โดยทั่วไปทำจากแผ่นลามิเนตสามชั้นสำหรับการขึ้นรูปเว็บ:

- โพลีเอไมด์ที่มีทิศทาง (OPA): ชั้นนอกให้ความเหนียวและทนทานต่อการเจาะ

- แผ่นอลูมิเนียมฟอยล์ (Alu) : ชั้นกลางซึ่งเป็นหัวใจของกำแพงกั้น มีหน้าที่ทำให้บรรจุภัณฑ์แทบจะกันน้ำได้

- โพลีไวนิลคลอไรด์ (PVC): ชั้นในซึ่งทำหน้าที่เป็นชั้นปิดผนึกและช่วยให้เกิดความเทอะทะและขึ้นรูปได้

ฝาปิดยังทำจากฟอยล์อลูมิเนียมที่เข้ากันได้ แตกต่างจากบรรจุภัณฑ์แบบใสทั่วไป บรรจุภัณฑ์ Alu Alu จะทึบแสงอย่างสมบูรณ์ แสดงถึงระดับการปกป้องที่สูงกว่าภายใน

ความแตกต่างที่สำคัญในการผลิตคือแผ่นอลูมิเนียมฟอยล์จะไม่ได้รับความร้อน แต่จะถูก "ขึ้นรูปเย็น" ซึ่งหมายความว่าแผ่นอลูมิเนียมฟอยล์จะถูกกดลงในแม่พิมพ์โดยใช้แม่พิมพ์แรงดันสูง กระบวนการปั๊มนี้จะยืดแผ่นลามิเนตให้เป็นรูปร่างของโพรงโดยไม่ใช้ความร้อน ทำให้รักษาความสมบูรณ์ของแผ่นอลูมิเนียมฟอยล์ได้อย่างสมบูรณ์

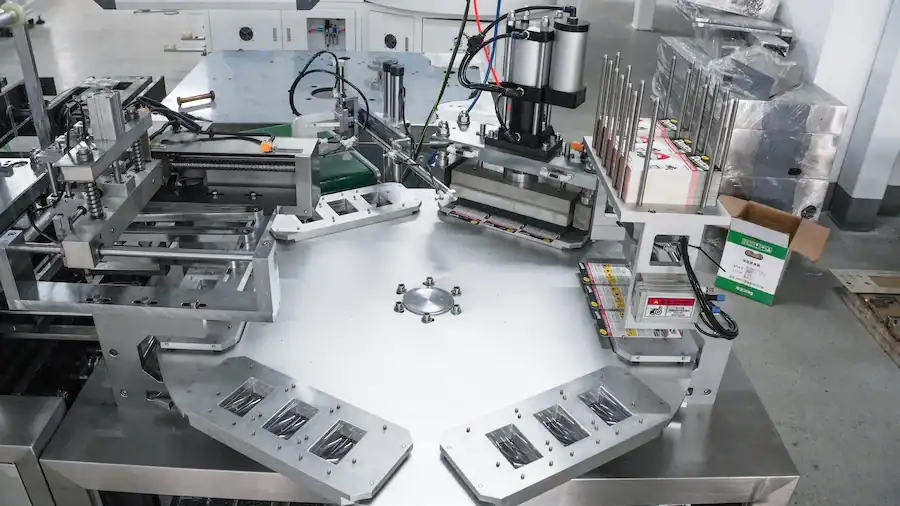

แผ่นซีลความร้อนอลูมิเนียม-พลาสติก จาก Grand DPP-270

การเผชิญหน้าระหว่าง Alu Alu กับ Standard Blister

เพื่อให้เข้าใจถึงความแตกต่างอย่างแท้จริง เราลองเปรียบเทียบความแตกต่างเหล่านี้ตามปัจจัยสำคัญหลายๆ ประการกัน

1. การป้องกันสิ่งกีดขวาง: ปัจจัยในการตัดสินใจ

นี่คือความแตกต่างที่สำคัญที่สุดระหว่างทั้งสอง

- พุพองมาตรฐาน: ช่วยป้องกันได้ดี แต่พลาสติก (แม้แต่ PVC เคลือบ PVDC) ก็ไม่เหมาะกับการปิดผนึก เมื่อเวลาผ่านไป ไอระเหยน้ำและออกซิเจนจำนวนเล็กน้อยสามารถแทรกซึมเข้าไปในฟิล์มพลาสติกได้ ซึ่งอาจเป็นอันตรายต่อยาที่มีความไวสูงหรือยาที่ดูดความชื้นได้

- อะลู อะลู บลิสเตอร์: ให้การปิดผนึกแบบเกือบสนิท ฐานแผ่นอลูมิเนียมขึ้นรูปเย็นและฝาปิดอลูมิเนียมสร้างป้อมปราการที่ป้องกันความชื้น ออกซิเจน แสง และก๊าซอื่นๆ ได้ 100% สำหรับยาที่เสื่อมสภาพอย่างรวดเร็วเมื่อสัมผัสกับองค์ประกอบเหล่านี้ อาลู อาลู บรรจุภัณฑ์ไม่ใช่แค่ทางเลือกแต่มันเป็นสิ่งจำเป็น

ผู้ชนะ: อาลู อาลูโดยมีส่วนต่างอย่างเห็นได้ชัด

2. วัสดุและกระบวนการผลิต

วิธีการผลิตบรรจุภัณฑ์เหล่านี้ส่งผลโดยตรงต่อคุณสมบัติและเครื่องจักรที่จำเป็น

- พุพองมาตรฐาน: ใช้กระบวนการเทอร์โมฟอร์มมิ่ง ฟิล์ม PVC จะถูกให้ความร้อนเพื่อให้นิ่มและยืดหยุ่น จากนั้นจึงขึ้นรูปด้วยสูญญากาศหรือแรงดัน กระบวนการนี้รวดเร็วและประหยัดพลังงาน เป็นมาตรฐาน เครื่องปิดปากถุงแบบพุพอง จากนั้นปิดฝาด้วยแผ่นฟอยล์

- อะลู อะลู บลิสเตอร์: ใช้กระบวนการขึ้นรูปเย็น พิเศษ เครื่องอัดอลู ใช้แรงกดทางกลสูง (การปั๊ม) เพื่อกดแผ่นลามิเนตลงในแม่พิมพ์ กระบวนการนี้ช้ากว่าและต้องใช้เครื่องจักรที่ทนทานและเฉพาะทางมากกว่า นอกจากนี้ โพรงมักจะมีขนาดใหญ่กว่าและโค้งมนกว่า เพื่อรองรับการยืดของวัสดุโดยไม่ทำให้ชั้นอลูมิเนียมแตก

ผู้ชนะ: พุพองมาตรฐาน เพื่อความรวดเร็วและเรียบง่ายในการผลิต

3. ความโปร่งใสเทียบกับความทึบ

- พุพองมาตรฐาน: ช่องพลาสติกใสช่วยให้สามารถมองเห็นผลิตภัณฑ์ภายในได้

- อะลู อะลู บลิสเตอร์: ทึบแสงอย่างสมบูรณ์ คุณไม่สามารถมองเห็นผลิตภัณฑ์ได้จนกว่าคุณจะดึงออกจากบรรจุภัณฑ์ แม้ว่าจะช่วยป้องกันการเสื่อมสภาพจากแสง แต่ก็ทำให้ไม่สามารถยืนยันด้วยสายตาได้

ผู้ชนะ: ขึ้นอยู่กับลำดับความสำคัญ พุพองมาตรฐาน เพื่อการมองเห็น; อาลู อาลู เพื่อการป้องกันแสง

4. ต้นทุนและขนาดบรรจุภัณฑ์

- พุพองมาตรฐาน: วัตถุดิบ (PVC และฟอยล์ปิดฝาแบบมาตรฐาน) มีราคาถูกกว่า กระบวนการเทอร์โมฟอร์มยังช่วยให้ออกแบบการ์ดพุพองได้เล็กลง กะทัดรัดขึ้น และมีมุมที่คมขึ้น ช่วยลดการใช้วัสดุและต้นทุนโดยรวม

- อะลู อะลู บลิสเตอร์: ฟอยล์ลามิเนตหลายชั้นมีราคาแพงกว่ามาก กระบวนการขึ้นรูปเย็นต้องใช้มุมร่างที่มากขึ้น (ต้องลาดเอียงมากขึ้น) ส่งผลให้ขนาดบรรจุภัณฑ์โดยรวมใหญ่ขึ้นเพื่อบรรจุแท็บเล็ตจำนวนเท่าเดิม ทำให้ต้นทุนวัสดุและต้นทุนบรรจุภัณฑ์รอง (กล่องกระดาษแข็ง) เพิ่มขึ้น

ผู้ชนะ: พุพองมาตรฐาน เพื่อความคุ้มค่าและมีดีไซน์ที่กะทัดรัด

ห้องเครื่อง: เครื่องจักรสำหรับบรรจุภัณฑ์แบบพุพองและแบบอะลูมิเนียม

การผลิตแพ็คเกจเหล่านี้ต้องอาศัยเครื่องจักรที่ซับซ้อนและมีความแม่นยำสูง แม้ว่าเครื่องจักรระดับไฮเอนด์บางเครื่องสามารถกำหนดค่าให้จัดการกระบวนการทั้งสองได้ แต่ก็มีความแตกต่างที่สำคัญ

- เครื่องบรรจุพุพอง: เครื่องจักรมาตรฐานจะมีสถานีทำความร้อนสำหรับการขึ้นรูปฟิล์มพลาสติกด้วยความร้อน สถานีป้อนผลิตภัณฑ์ สถานีปิดผนึกสำหรับ ฟอยล์ปิดฝาเภสัชและสถานีตัด ซึ่งมีจำหน่ายทั่วไปจากผู้ผลิตทั่วโลก รวมถึงตัวเลือกที่มีการแข่งขันมากมาย เครื่องบรรจุพุพองจีน ซัพพลายเออร์

- เครื่องอลูอลู (เครื่องขึ้นรูปเย็น) : อุปกรณ์ชิ้นนี้มีความทนทานและมีความเฉพาะทางมากกว่า โดยขาดสถานีทำความร้อน แต่มีสถานีกดแบบกลไกที่ทรงพลังพร้อมเครื่องมือปั๊มเฉพาะ สถานีป้อนและปิดผนึกมีความคล้ายคลึงกัน แต่โครงและกลไกทั้งหมดของเครื่องจักรจะต้องสร้างขึ้นให้ทนต่อแรงที่สูงกว่าในการขึ้นรูปเย็น

สำหรับผู้ผลิตที่มองหาความคล่องตัว การลงทุนใน เครื่องอัดอลู ซึ่งมีเครื่องมือที่ใช้แทนกันได้สำหรับการขึ้นรูปด้วยความร้อนและการขึ้นรูปเย็น ถือเป็นทางเลือกเชิงกลยุทธ์ ซึ่งช่วยให้บริษัทสามารถผลิตพุพอง PVC มาตรฐานสำหรับผลิตภัณฑ์ที่ทนทานและพรีเมียมได้ อาลู อาลู บรรจุภัณฑ์สำหรับสูตรที่ละเอียดอ่อนทั้งหมดบนแพลตฟอร์มเดียว หลักการเดียวกันนี้ใช้ได้กับอุปกรณ์ R&D ที่ง่ายกว่า เช่น เครื่องปิดปากถุงแบบพุพองซึ่งจะต้องได้รับการปรับเทียบอย่างถูกต้องสำหรับประเภทวัสดุและพารามิเตอร์การปิดผนึกที่แตกต่างกัน เทคโนโลยีนี้ยังได้รับการดัดแปลงสำหรับรูปแบบอื่นๆ ด้วย โดยมีหลักการบางอย่างที่ใช้ในขั้นสูง เครื่องบรรจุซองยาแบบกลม สำหรับผงขนาดรับประทานครั้งเดียว

บทสรุป: การเลือกที่ถูกต้อง

แล้วจะเลือกยังไงดีล่ะ? การตัดสินใจเลือกระหว่าง อาลู อาลู และมีมาตรฐาน แผลพุพอง บรรจุภัณฑ์ไม่ได้ขึ้นอยู่กับว่าอันไหน "ดีกว่า" โดยรวม แต่ขึ้นอยู่กับว่าอันไหนเหมาะกับผลิตภัณฑ์ของคุณโดยเฉพาะ

เลือกบรรจุภัณฑ์แบบพุพองมาตรฐานหาก:

ผลิตภัณฑ์ของคุณมีเสถียรภาพและไม่ไวต่อความชื้น แสง หรือออกซิเจนมากเกินไป

ความคุ้มทุนถือเป็นข้อกังวลหลัก

การมองเห็นผลิตภัณฑ์เป็นสิ่งสำคัญสำหรับผู้ใช้ปลายทาง

คุณต้องการขนาดบรรจุภัณฑ์ที่กะทัดรัดเพื่อลดต้นทุนการจัดส่งและการจัดเก็บ

เลือกบรรจุภัณฑ์แบบพุพอง Alu Alu หาก:

ยาของคุณมีความชื้นสูง (ดูดซับความชื้น) หรือไวต่อแสงและออกซิเจน

คุณกำลังส่งออกไปยังเขตร้อน (เขตภูมิอากาศ III และ IV) ซึ่งมีความร้อนและความชื้นสูง

คุณจะต้องรับประกันอายุการใช้งานที่ยาวนานที่สุดเท่าที่จะเป็นไปได้

ค่าเบี้ยประกันนี้สมเหตุสมผลเมื่อพิจารณาจากข้อกำหนดความเสถียรของยาที่มีมูลค่าสูง

โดยการเข้าใจความแตกต่างที่สำคัญเหล่านี้ คุณจะสามารถร่วมงานกับผู้จัดหาอุปกรณ์อย่าง GrandPack ได้ดีขึ้น เพื่อสร้างสายการบรรจุภัณฑ์ที่รับประกันความปลอดภัย คุณภาพ และประสิทธิภาพของผลิตภัณฑ์ยาของคุณตั้งแต่การผลิตจนถึงผู้ป่วย

คำถามที่พบบ่อย (FAQs) เกี่ยวกับเครื่องบรรจุภัณฑ์แบบพุพอง

1. เครื่องบรรจุแบบพุพองเครื่องเดียวสามารถจัดการกับบรรจุภัณฑ์ทั้ง PVC/Alu และ Alu/Alu ได้หรือไม่ ใช่ เครื่องผลิตพุพองคุณภาพสูงสมัยใหม่หลายเครื่องได้รับการออกแบบมาให้มีความยืดหยุ่น โดยสามารถติดตั้งสถานีขึ้นรูปแยกกันได้สองสถานี สถานีหนึ่งสำหรับการขึ้นรูปด้วยความร้อน (สำหรับ PVC) และอีกสถานีหนึ่งสำหรับการขึ้นรูปเย็น (สำหรับ Alu Alu) โดยการเปลี่ยนเครื่องมือและเลี่ยงสถานีที่ไม่ได้ใช้ ผู้ผลิตสามารถผลิตบรรจุภัณฑ์ทั้งสองประเภทบนเครื่องเดียว ซึ่งมีประสิทธิภาพสูงสำหรับบริษัทที่มีผลิตภัณฑ์หลากหลายประเภท

2. การตรวจสอบคุณภาพที่สำคัญที่สุดที่เครื่องทำพุพองคืออะไร เครื่องบรรจุพุพองสมัยใหม่มีระบบการควบคุมคุณภาพอัตโนมัติหลายระบบ ระบบที่สำคัญที่สุด ได้แก่:

- ระบบการมองเห็น: กล้องตรวจสอบโพรงหลังจากการอุดฟันเพื่อตรวจหาเม็ดยาที่หาย แตก หรือไม่ถูกต้อง

- การตรวจจับรูเข็ม: สำหรับฟอยล์ Alu Alu ระบบเฉพาะทางสามารถตรวจจับรูขนาดเล็กที่อาจส่งผลกระทบต่อสิ่งกั้นได้

- การตรวจสอบความสมบูรณ์ของซีล: การทดสอบการสลายตัวของแรงดันหรือสุญญากาศสามารถทำได้แบบออฟไลน์เพื่อให้แน่ใจว่าการปิดผนึกรอบๆ ตุ่มพองแต่ละอันสมบูรณ์แบบ

- การตรวจสอบรหัส (OCR/OCV): เครื่องสแกนตรวจสอบว่าหมายเลขชุดที่พิมพ์และวันที่หมดอายุนั้นถูกต้องและอ่านออก

3. ระบบการป้อนอาหารบนเครื่องบรรจุแบบพุพองมีความสำคัญมากเพียงใด? ระบบการป้อนมีความสำคัญอย่างยิ่งต่อความเร็วและความแม่นยำโดยรวมของเครื่องจักร เครื่องป้อนที่ไม่ดีอาจทำให้ผลิตภัณฑ์แตกหัก บรรจุไม่ถูกต้อง และเครื่องหยุดทำงานซึ่งมีค่าใช้จ่ายสูง เครื่องป้อนเฉพาะได้รับการออกแบบมาสำหรับผลิตภัณฑ์ที่มีรูปร่างเฉพาะ (เม็ดกลม แคปซูลทรงรี เป็นต้น) และใช้วิธีการต่างๆ เช่น รางสั่นสะเทือน แปรง หรือช่องเฉพาะ เพื่อวางผลิตภัณฑ์หนึ่งชิ้นลงในแต่ละช่องอย่างนุ่มนวลและแม่นยำด้วยความเร็วสูงมาก

4. เครื่องปิดกล่องพุพองต้องบำรุงรักษาอย่างไร? การบำรุงรักษาอย่างสม่ำเสมอเป็นสิ่งสำคัญต่ออายุการใช้งานและประสิทธิภาพ ซึ่งรวมถึง:

- การทำความสะอาดรายวัน: โดยเฉพาะบริเวณการป้อนและพื้นผิวการปิดผนึกเพื่อป้องกันการสะสมและการปนเปื้อนข้ามของผลิตภัณฑ์

- การหล่อลื่นปกติ: ของชิ้นส่วนเคลื่อนไหวทั้งหมดตามที่ผู้ผลิตกำหนด

- การตรวจสอบเครื่องมือ: ตรวจสอบแม่พิมพ์ขึ้นรูป แผ่นปิดผนึก และเครื่องมือตัดเพื่อดูว่ามีการสึกหรอหรือไม่เป็นประจำ

- การสอบเทียบ: ตรวจสอบอุณหภูมิของสถานีปิดผนึกและแรงดันของสถานีการขึ้นรูป/ปิดผนึกเป็นระยะๆ เพื่อให้แน่ใจว่ามีคุณภาพสม่ำเสมอ