Grand Yatay Etiketleme Makinesi Özellikleri – Grand Solutions

Jöleli Ayı Makinesi – Otomatik Yüksek Hızlı Jöleli Şeker Üretim Hattı

giriiş

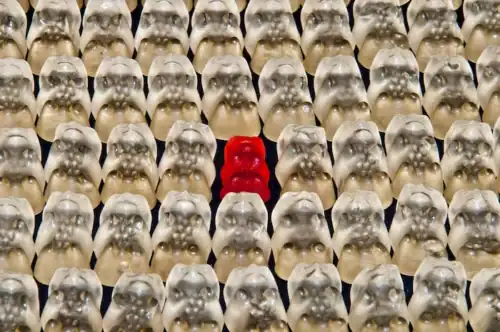

The global gummy candy market is booming. Soft candies (like gummy bears) reached about $21.4 billion worldwide in 2022, with annual growth projected around 5–6%. Busy consumers now demand more from their candies – not just sweetness but health benefits (sugar-free, vegan, vitamin-fortified), natural ingredients, and novel flavors or shapes. Recent research even shows formulators adding plant extracts and stevia to create antioxidant-rich, reduced-sugar gummies. In short, gummy candy is evolving rapidly. Entrepreneurs and manufacturers have a real opportunity to innovate – but success requires the right equipment.

Today’s gummy production lines are fully automated systems that turn raw ingredients into consistent gummy treats. These integrated lines automate every step – from mixing and cooking the gelatin/sugar syrup to depositing it into molds, cooling the molded gummies, and finally packaging the finished candies. By synchronizing each stage, the line guarantees that each gummy (bear, worm, fish, or other shape) comes out the same size, weight and quality. This level of automation is essential for large-scale manufacturing. For example, top gummy machines (such as Grand Packaging’s SE-300 line) use PLC controls and servo-driven depositors so that operators simply set recipes and press Start, while the system produces tens of thousands of gummies per hour.

Key steps in a modern gummy production line include:

- Mixing & Cooking: Ingredients (gelatin or pectin, sugar, glucose syrup, water, flavors and acids) are precisely measured and heated in mixers or kettles. Precise temperature control (often with vacuum or homogenization) yields a smooth, bubble-free gummy syrup.

- Depositing & Molding: The warm gummy syrup is pumped into molds via a servo-driven depositor. Multiple nozzles fill many cavities at once, creating thousands of identical gummies per minute. Silicone or starch molds define the candy’s shape – classic bears one day, gummy worms or snakes the next. (Switching shapes is as simple as changing the mold plates.)

- Cooling & Setting: Filled trays enter a multi-zone cooling tunnel that gradually chills the candies to solidify their gel structure. Slowing the temperature drop prevents cracks or distortions. Proper cooling is vital – without it, gummies wouldn’t harden correctly. By the tunnel’s end, each gummy is set and firm enough to demold (e.g. pop out of silicone molds or release from starch).

- Ambalajlama: Finally, conveyors move the demolded gummies into automated packaging machines. Sophisticated systems count or weigh the candies and fill them into bags, pouches, bottles or sachets. Common equipment includes vertical form-fill-seal (VFFS) baggers and multi-head weighers. For example, a gummy line might use a multi-channel weigher to portion candy into bags or a rotary filling system for bottles. Many lines also include integrated labelers, heat-sealers, and inspection units to complete the process. Modern systems even incorporate vision sensors and metal detectors as quality checks before shipping.

-500x333.jpg)

Versatility of Gummy Machines: A single production line can make many gummy varieties without major new investment. By swapping molds and adjusting recipes, manufacturers can produce bears, worms, snakes, fish, fruit slices, vitamin-shaped gummies, etc.. Multi-color or dual-flavor gummies are also possible using dual-hopper systems. This flexibility lets brands launch seasonal treats or niche products (sugar-free gummies, vitamin supplements, exotic flavors, etc.) quickly. In practice, modern gummy machines are built to handle diverse formulas – whether gelatin- or pectin-based – and even specialty ingredients like vitamins or botanicals. For example, one manufacturer notes that their line can run both conventional and sugar-free formulations simply by adjusting temperatures and mixing times. Consumer trends show demand for novelty forms (e.g. gummy snakes or “gummy snake candy”) and functional ingredients, so this production flexibility is a major advantage.

Key Equipment Features: High-end gummy machines are designed for speed, accuracy and hygiene. The mixing kettles and conveyors are often equipped with temperature controls and quick-clean features. Depositors use precise pumps or pistons to dispense exact volumes, reducing waste. Cooling tunnels have multiple zones for fine-tuned chilling. In packaging, multi-head weighers and batchers dose exact counts, while checkweighers and vision systems verify fill levels and appearance. For example, Grand Packaging’s vertical-feed wrap-around labeling machine applies labels at up to 200 pieces per minute ile ±1.0 mm placement accuracy, ensuring every gummy jar or bag looks perfect on the shelf. Advanced counting machines use infrared sensors and anti-dust features to achieve near-100% accuracy, minimizing giveaways and ensuring regulatory compliance.

Integrated Gummy Production Solutions: Grand Packaging Machinery offers complete gummy production lines and support equipment in one package. Their flagship Büyük Sakızlı SE-300 line is an all-in-one system that automatically mixes, cooks, and deposits candy mass into molds, then demolds and transports the gummies for drying. This turn-key line can produce tens of thousands of gummy pieces per hour with minimal labor. All food-contact parts are 304 stainless steel for easy sanitation, meeting global safety standards. Grand also provides auxiliary machines: multi-channel counting lines (originally for pills, but adapted to candies) that handle chewing gum and gummy pieces with high accuracy; multi-head weighers and VFFS baggers for pouch filling; and their precision labeling machines for bottle/jar labeling. Each system is modular and customizable – for example, the vertical wrap-labeler supports label reels up to 350 mm diameter, and its height/angle adjustments accommodate different container sizes. In short, Grand’s gummy solutions cover everything from raw ingredient handling to finished package, allowing confectioners to set up a turnkey gummy line quickly.

Quality, Efficiency and Compliance: Modern gummy machines emphasize food safety and efficiency. Grand’s equipment is designed for easy cleaning (smooth welds, quick-release parts) and meets CE, GMP and FDA regulations as needed. Intelligent heating/cooling controls and insulated kettles improve energy use, reducing operating costs. And customer support – including training, manuals and after-sales service – helps manufacturers optimize their lines. By using such advanced machinery, gummy producers can scale up output without sacrificing consistency. The result is a high-quality gummy candy (bear, worm, snake, or vitamin shape) that delights consumers and drives sales.

In conclusion

The Gummy Bear Machine and its associated packaging equipment are key to capitalizing on the expanding gummy candy market.

Whether you’re launching a new gummy brand or expanding an existing candy line, an automated gummy production and packaging line maximizes efficiency and product consistency. Grand Packaging Machinery’s comprehensive solutions make it easy to mix, form, inspect, count, and package gummy bears (and all gummy varieties) at industrial scale.

By integrating mixing, depositing, labeling and bagging equipment in one line, manufacturers gain a competitive edge – higher throughput, lower labor cost, and consistent premium quality.

Referanslar:

Formulation of functional gummy candies with antioxidants and stevia, Heliyon (2024)pubmed.ncbi.nlm.nih.gov.

GrandPackMachine Blog (Apr 2025), "SE-300 Sakızlı Şeker Üretim Hattı ile Sakızlı Şeker Ayıcıklarının Piyasaya Sürülmesi” – industry data and trends.

Yundu Machinery (Jun 2025), “The Ultimate Guide: Gummy Candy Production Line” – overview of production steps (mixing, depositing, cooling, packaging).

GrandPackMachine Blog (2025), Pharma Packaging Line – Counting Line – features of automated counting machines (handles candies with high accuracy)grandpackmachine.com.

Grand Packaging Machinery technical sheet – Vertical Feeding Wrap-Around Labeling Machine specs (10–200 pcs/min, ±1.0 mm).

Packaging equipment references – e.g., Yundu (Jun 2025) on cooling tunnels, baggers and labelers