Máy chiết rót và đóng gói túi truyền dịch | Giải pháp cho túi mềm và chai nhựa chính xác

Máy chiết rót và đóng gói túi truyền dịch Grand đảm bảo chiết rót và đóng gói tự động có độ chính xác cao cho túi mềm truyền dịch và chai nhựa. Tuân thủ các tiêu chuẩn GMP, FDA và CE, hệ thống của chúng tôi hỗ trợ nhiều dung tích thể tích, chiết rót vô trùng và các giải pháp đóng gói có rào cản cao.

Giải pháp đóng gói và niêm phong túi truyền dịch sáng tạo

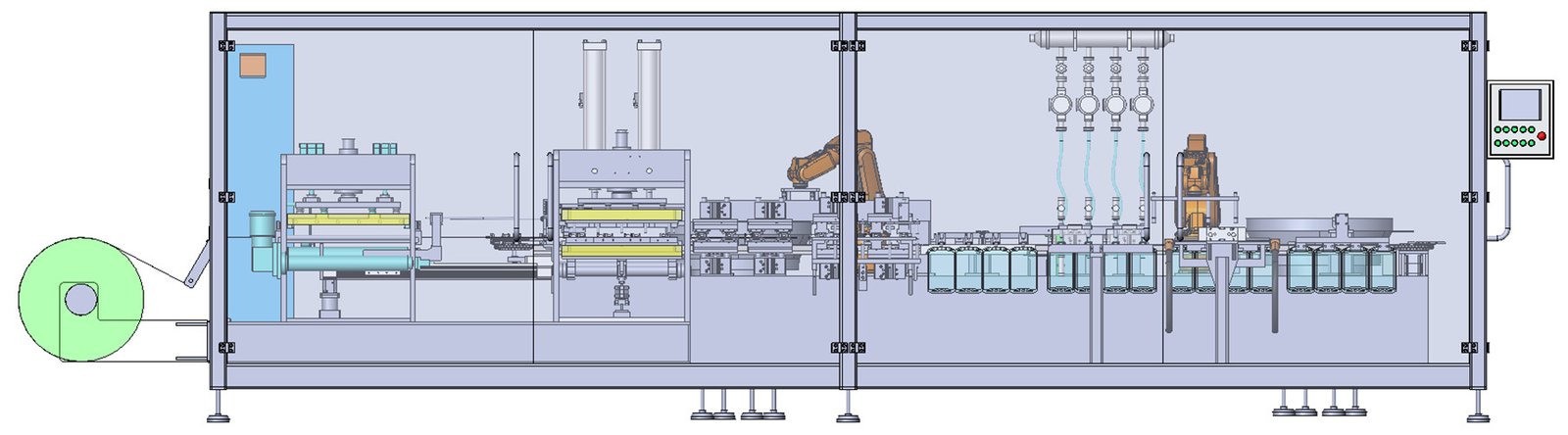

Máy chiết rót và đóng gói túi truyền dịch

Lớn'S Máy chiết rót và đóng gói túi truyền dịch là một hệ thống đóng gói dược phẩm tiên tiến được thiết kế cho túi mềm truyền dịch và chai nhựa.

Giải pháp của chúng tôi tích hợp tự động hóa, định lượng chính xác và niêm phong vô trùng để đảm bảo an toàn và hiệu quả cao nhất cho sản phẩm.

Tiêu chuẩn cao & Hiệu quả cao

Với khả năng xử lý các sản phẩm 30-5000ml, hệ thống này cung cấp một hệ thống GMP đa năng và FDA- Quy trình chiết rót tuân thủ giúp nâng cao hiệu quả sản xuất và tính toàn vẹn của sản phẩm.

Cho dù xử lý túi truyền nhiều lớp không phải PVC hay chai truyền bằng nhựa, máy của chúng tôi đều đảm bảo chiết rót đồng đều, không bị nhiễm bẩn và niêm phong an toàn.

Điểm nổi bật của việc đổ đầy túi truyền dịch

✅ Điền sản phẩm kép mỗi chu kỳ để tăng năng suất

✅ Có thể tùy chỉnh cho các dạng sản phẩm khác nhau và khối lượng

✅ Khả năng hàn nhiệt để đảm bảo an toàn cho bao bì

✅ Xử lý sự cố từ xa cho hiệu quả hoạt động

✅ Hệ thống RAB tích hợp để chiết rót vô trùng

✅ Dập nóng số lô theo thời gian thực

✅ Chức năng có thể mở rộng cho nhu cầu sản xuất trong tương lai

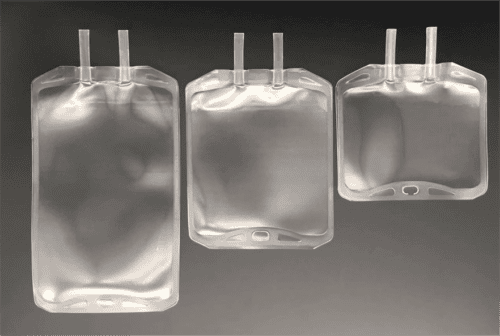

Túi truyền dịch không phải PVC

Bao bì an toàn, vô trùng và bền vững

của Grand túi truyền dịch không phải PVC được sản xuất trong một Phòng sạch cấp C sử dụng màng truyền đồng đùn nhiều lớp. Được thiết kế để đảm bảo an toàn và ổn định, bao bì của chúng tôi đảm bảo:

✔ Độ ổn định hóa học cao không có chất chiết xuất

✔ Vật liệu không độc hại, không chứa DEHP vì sự an toàn của bệnh nhân

✔ Khả năng tương thích khử trùng đầu cuối 121°C

✔ Tùy chọn khử trùng bằng chiếu xạ để chiết rót vô trùng

✔ Mức độ nội độc tố dưới 25EU/ml

✔ Bao bì sạch sẽ, bền bỉ với thời hạn sử dụng kéo dài

✔ Tuân thủ các tiêu chuẩn quốc gia và quốc tế

✔ Có nhiều dung tích khác nhau (50-3000ml)

Ứng dụng lý tưởng cho túi truyền dịch không phải PVC:

- Tiêu chuẩn dung dịch truyền tĩnh mạch

- Thẩm phân phúc mạc và dịch tưới rửa

- Băng y tế sợi polysaccharide

- Dinh dưỡng y tế dựa trên pectin và protein

- Môi trường nuôi cấy tế bào và dung dịch pha loãng vắc-xin

- Thuốc sắc thuốc y học cổ truyền Trung Quốc

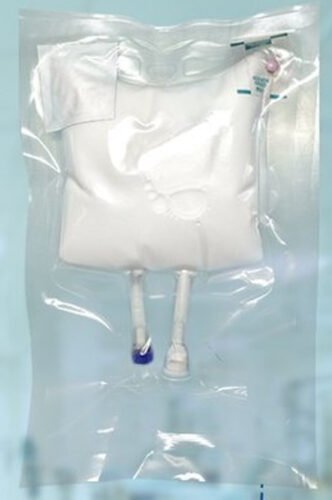

Túi ngoài có rào cản cao

Bảo vệ tối đa cho bao bì truyền dịch

Để duy trì sự ổn định của thuốc và kéo dài thời hạn sử dụng, Grand cung cấp túi ngoài có rào cản cao với đặc tính bảo vệ đặc biệt:

✔ Độ trong suốt cao cho một sản phẩm cao cấp

✔ Chịu được nhiệt độ tiệt trùng bằng nồi hấp 121°C

✔ Rào cản oxy cao cấp để ngăn chặn quá trình oxy hóa

✔ Khả năng chống hơi nước để duy trì nồng độ thuốc và cân bằng pH

✔ Tính chất kháng khuẩn để ngăn ngừa ô nhiễm

✔ Có sẵn công thức tùy chỉnh cho các ứng dụng dược phẩm cụ thể

Bao bì rào cản cao của chúng tôi đặc biệt phù hợp với thuốc điều trị, axit amin và thuốc tiêm Trung Quốc, đảm bảo tính toàn vẹn của sản phẩm và an toàn cho bệnh nhân.

Chuyển đổi quy trình đóng gói truyền dịch của bạn

của Grand Máy chiết rót và đóng gói túi truyền dịch kết hợp công nghệ tiên tiến với quy trình nghiêm ngặt GMP, FDA và Tuân thủ CE.

Cho dù tối ưu hóa các dây chuyền sản xuất hiện có hay áp dụng giải pháp túi truyền dịch không phải PVC, chúng tôi cung cấp hệ thống đóng gói dược phẩm tùy chỉnh, hiệu quả và vô trùng để đáp ứng nhu cầu ngày càng thay đổi của ngành.

Hãy liên hệ với chúng tôi ngay hôm nay để được tư vấn và khám phá những điều tốt nhất giải pháp đóng gói truyền dịch phù hợp với nhu cầu của bạn.

Dây chuyền sản xuất túi truyền dịch