What makes a vision inspection machine efficient? | Grand

Are Pill Capsules Bad for You? Capsules vs. Powder vs. Liquid Absorption Guide

Ultimate Guide to Vial and Ampoule Filling Machine Selection

Introduction

In the pharmaceutical and biotech industries, precision is not just a goal; it is a requirement. Whether you are packaging vaccines, essential oils, or lyophilized powders, the integrity of your container is paramount. For many manufacturers, the choice comes down to two primary container types: Vials and Ampoules.

However, selecting the right machinery to handle these delicate glass containers can be overwhelming. With options ranging from compact desktop units to high-speed vial filling lines, making the wrong choice can lead to production bottlenecks or GMP compliance issues.

At Grand Packaging Machinery, we believe an informed customer is our best partner. This guide will walk you through the essential differences between these containers, the specific data you need to provide to get an accurate machine quote, and how our pharmaceutical vial filling machine solutions can be tailored to your specific needs.

1. Back to Basics: Vials vs. Ampoules

Before diving into machinery, it is crucial to understand the packaging formats. While they may look similar to the untrained eye, their sealing methods and applications differ significantly.

What is a Vial?

A vial is a small glass or plastic vessel used to store medication as liquids, powders, or capsules.

Sealing Mechanism: They are typically sealed with a rubber stopper (plug) and secured with a metal cap (usually aluminum or aluminum-plastic) that is crimped onto the neck.

Usage: Vials can be designed for single-dose or multi-dose use. They are the standard for injectable drugs, essential oils, and freeze-dried powders.

Machine Requirement: A vial filling machine must be able to fill, insert a stopper, and crimp a cap.

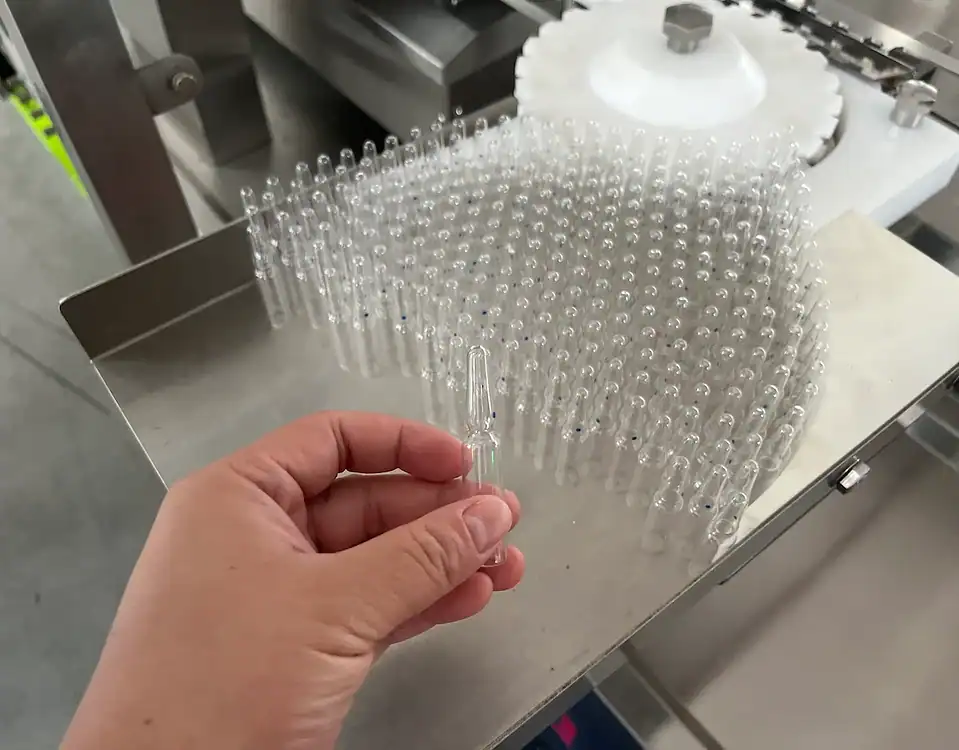

What is an Ampoule?

An ampoule is a sealed glass vial used to preserve a sample, usually a solid or liquid.

Sealing Mechanism: Ampoules are hermetically sealed by melting the thin top of the glass neck with an open flame (wire drawing or pulling method).

Usage: Strictly single-dose. Once opened (by snapping the neck), it cannot be resealed. This makes them ideal for unstable chemical compounds that need protection from oxygen.

Machine Requirement: An ampoule filler requires burners and precision clamps to melt and seal the glass without cracking it.

Key Differences at a Glance

| Feature | Vial (Injection Bottle) | Ampoule |

| Material | Glass (Tubular/Molded) or Plastic | All Glass |

| Closure | Rubber Stopper + Crimp Cap | Fusion Sealed (Melted Glass) |

| Reusability | Can be multi-dose (resealable via stopper) | Single-use only |

| Opening | Needle puncture or removing cap | Snapping the glass neck |

| Primary Machine Function | Filling $\rightarrow$ Plugging $\rightarrow$ Crimping | Filling $\rightarrow$ Flame Sealing |

2. The Buyer’s Checklist: How to Request a Quote Efficiently

One of the biggest delays in procuring a vial filling machine is the back-and-forth communication regarding specifications. To get a fast, accurate proposal from a manufacturer like Grand, you should prepare the following "Pharmaceutical Machinery Selection" data package.

A. The Container Specs (Crucial)

Machines utilize "star wheels" or "turntables" to move bottles. These are custom-machined to fit your specific bottle diameter.

Dimensions: Provide the diameter and height of every bottle size you intend to run. Note that different diameters usually require different mold changeover parts.

Cap & Stopper Details: Are you using butyl rubber stoppers? Are the caps pure aluminum or aluminum-plastic (flip-off)? The capping head requires different hardness settings for different materials to ensure a clean seal.

Tolerance: If you have cheap glass bottles with high dimensional variance (height differences >2mm), tell your supplier immediately, as this affects the capping height adjustment.

B. The Product (Liquid vs. Powder)

Liquids: What is the viscosity? For water-like substances, peristaltic pumps are ideal because the liquid only touches the tubing, ensuring sterility. For thick oils, a piston pump may be required.

Powders: What is the fill weight? (e.g., 0.15g to 1g). We need to know the density to calibrate the auger screw correctly.

C. Production Capacity

Be realistic about your speed requirements.

- Entry Level: 30–40 bottles per minute (BPM) is standard for a compact monoblock system.

- High Speed: If you need 100–250 BPM, you will need a rotary high-speed machine rather than a single-head monoblock.

3. Grand Machinery Solutions: Tailored to Your Needs

At Grand, we categorize our solutions based on the material state (Liquid vs. Powder) and production scale. Here is a breakdown of our flagship vial filling equipment.

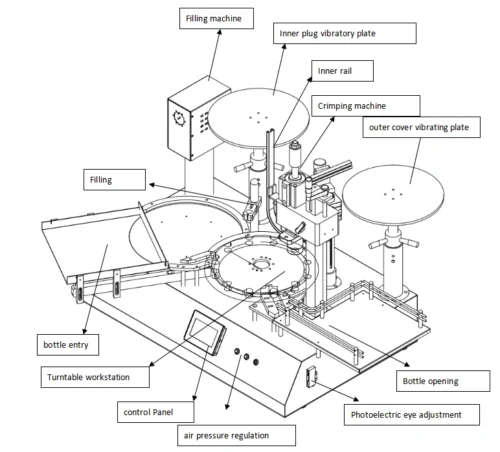

The Monoblock Series (Compact & Efficient)

For small to medium batches, we utilize a "Monoblock" design. This means the filling, stopper insertion, and capping all happen on a single rotary turntable. This saves space and ensures one operator can manage the whole machine.

1. Liquid Vial Filling (Model DHGX011T)

This is our versatile workhorse for essential oils, vaccines, and solvents.

- High Precision: We use peristaltic pumps which offer filling accuracy within 1%. This is critical for high-value pharmaceutical ingredients.

- No-Scratch Capping: Unlike older knife-style cappers, we use a four-blade crimping head. This ensures the aluminum cap is sealed tight without creating metal shavings or scratching the cap's aesthetic coating.

- Smart Changeover: The height of the turret can be adjusted in 20 seconds to accommodate different bottle heights.

- GMP Compliant: The machine features a fully enclosed design with 10mm hardened acrylic doors and uses 304 stainless steel, meeting GMP certification standards.

2. Powder Vial Filling (Model DHGX011F)

Filling powder into small vials is notoriously difficult due to dust and accuracy issues. Our automatic vial filling machine for powder addresses this with:

- Auger Dosing: A servo-driven screw (auger) controls the fill weight precisely, capable of handling micro-doses from 0.15g to 1g.

- Anti-Explosion Device: We utilize a mechanical device to stabilize the bottle during sealing. This prevents the dreaded "bottle burst" phenomenon that occurs if a glass vial is misaligned during the high-pressure capping process.

The High-Speed Production Line

For mass production, integrated lines are necessary.

1. High-Speed Capping (Series CZG18)

When your output requirement exceeds 100 bottles per minute, a desktop filler is insufficient. The CZG18 Rotary Capping Machine is designed for integration into a larger vial filling line.

Speed: Capable of processing 100 to 250 bottles per minute.

Reliability: It boasts a capping qualification rate of $\ge 99\%$, ensuring almost zero wastage of expensive pharmaceutical glass.

2. Grand Ampoule Filling Lines

Our ampoule lines feature advanced "wire drawing" filling heads18. This technology ensures the liquid is filled cleanly without dripping on the neck, which is crucial for the subsequent flame sealing process (carbonization on the neck can cause sealing failures).

4. Beyond Filling: Integration & Compatibility

A vial filling machine is rarely an island. It needs to talk to the rest of your factory.

Downstream Integration

One of the key features of Grand's designs is the standardized conveyor and output height.

Labeling: Our machines are designed with a "bottle collection tray" that can be easily removed to dock directly with a labeling machine conveyor.

Cartoning: The output speed of our fillers can be synchronized with automatic cartoning machines, ensuring a seamless flow from liquid filling to the final boxed product.

Intelligent Controls

Modern manufacturing requires data and ease of use. Our machines utilize top-tier automation components:

PLC & Touchscreen: We use Siemens or Xinje PLCs for robust control.

Sensors: Keyence optical sensors (Japan) are used for "No Bottle, No Fill" and "No Stopper, No Cap" logic. If a bottle is missing a stopper, the machine will alarm and stop before wasting a metal cap.

Conclusion

Choosing between a vial filling line and a standalone unit, or between liquid and powder configurations, depends entirely on your product characteristics and business goals.

If you are a startup or a lab producing small batches of high-value essential oils or freeze-dried powders, our DHGX011 Series (Monoblock) offers the perfect balance of small footprint and GMP compliance. For large-scale pharmaceutical contract manufacturers, our high-speed rotary lines ensure you meet market demand without compromising seal integrity.

Ready to configure your machine?

To get a quote within 24 hours, please send us:

Photos of your bottle, stopper, and cap.

Bottle diameter and height.

Target speed (Bottles Per Minute).

Material viscosity or density.