10 nhà sản xuất máy dập viên thuốc hàng đầu tại Trung Quốc (2025)

Viên nang gelatin mất bao lâu để tan? | GrandPack®

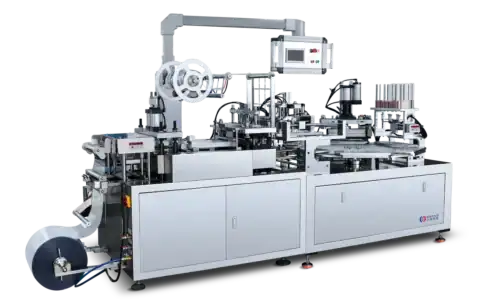

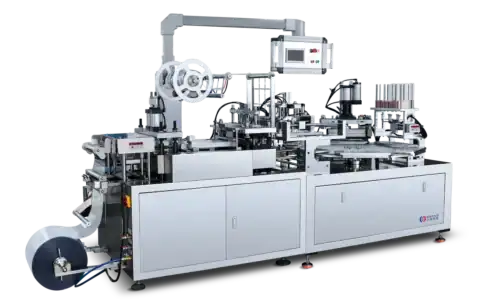

Máy đóng gói vỉ Grand AC-350 | Giải pháp đóng gói giấy và nhựa tốc độ cao

Hướng dẫn đầy đủ về máy đóng gói vỉ vỉ Grand AC-350

Trong thị trường bán lẻ cạnh tranh, bao bì sản phẩm không chỉ là lớp vỏ bảo vệ; đó còn là cái bắt tay đầu tiên với khách hàng. Nó truyền tải chất lượng, đảm bảo an toàn và cuối cùng là thúc đẩy doanh số. Đối với vô số sản phẩm — từ phần cứng và dụng cụ đến mỹ phẩm và văn phòng phẩm — vỉ đóng kín nửa mặt là tiêu chuẩn của ngành. Tuy nhiên, để đạt được vẻ ngoài sạch sẽ, chuyên nghiệp này một cách hiệu quả và trên quy mô lớn đòi hỏi thiết bị chuyên dụng.

Nhập vào Grand AC-350 Máy đóng gói vỉ giấy-nhựaHệ thống tiên tiến này được thiết kế để tự động hóa và hoàn thiện toàn bộ quy trình đóng gói vỉ, mang đến sản phẩm cuối cùng an toàn, đẹp mắt và sẵn sàng để bày bán. Hướng dẫn này sẽ khám phá hoạt động bên trong của cỗ máy mạnh mẽ này, các tính năng nổi bật và lý do tại sao nó là giải pháp tối ưu cho nhu cầu đóng gói của bạn.

Máy đóng gói vỉ là gì? Và nó khác biệt như thế nào?

Trước khi đi sâu vào chi tiết cụ thể của AC-350, điều quan trọng là phải trả lời một câu hỏi chính: Sự khác biệt giữa máy đóng gói vỉ và máy đóng gói máy đóng vỉ thông thường? Mặc dù nghe có vẻ giống nhau nhưng chức năng của chúng lại khác nhau.

Máy đóng vỉ "thông thường", thường thấy trong ngành dược phẩm, thường tạo ra một vỉ nhựa, đổ đầy (ví dụ, thuốc viên), rồi dán kín bằng màng nhôm. Mục tiêu là tạo ra một bao bì có thể bóc ra và được niêm phong kín khí.

MỘT máy đóng gói vỉMặt khác, máy in 3D Grand AC-350 được thiết kế cho kiểu đóng gói "niêm phong nửa mặt" phổ biến trong bán lẻ. Chức năng chính của nó là dán vỉ nhựa định hình lên thẻ giấy in. Ứng dụng của nó rất rộng, bao gồm mọi thứ, từ pin, dụng cụ đến mỹ phẩm và nhu yếu phẩm hàng ngày. Grand AC-350 là bậc thầy trong kiểu đóng gói đặc thù, có nhu cầu cao này.

Máy đóng gói vỉ hoạt động như thế nào? Phân tích từng bước

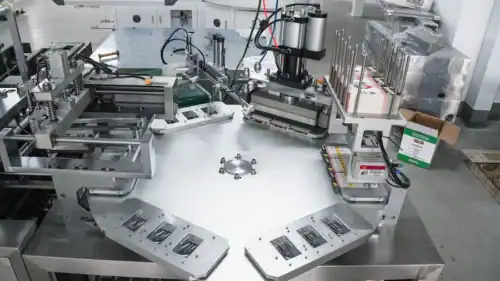

Hiểu biết về nguyên lý hoạt động của máy đóng gói vỉ Grand AC-350 thể hiện một bản giao hưởng của các chuyển động cơ học và tự động đồng bộ. Hệ thống mâm đĩa than sáu trạm, đảm bảo quy trình làm việc trơn tru và liên tục. Sau đây là cách nó biến đổi nguyên liệu thô thành thành phẩm:

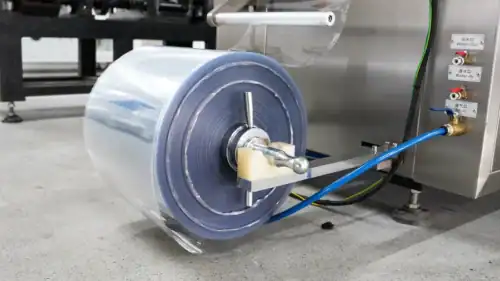

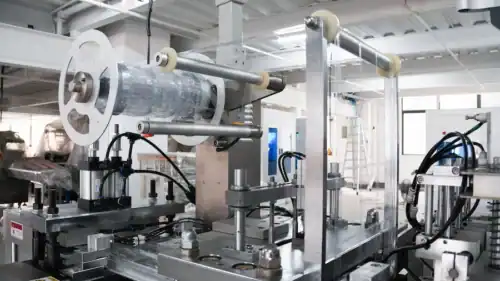

1. Tháo PVC/PET: Quy trình bắt đầu bằng việc lắp một cuộn màng nhiệt dẻo lớn (PVC hoặc PET) vào máy và tháo ra một cách trơn tru. Máy AC-350 có thể xử lý vật liệu có độ dày từ 0,18mm đến 0,5mm.

2. Sưởi ấm bằng điện và tạo vỉ: Màng phim sau khi được tháo cuộn sẽ đi qua trạm gia nhiệt điện, tạo độ dẻo. Ngay sau đó, màng phim được đưa vào khuôn định hình, tại đây áp lực được tạo ra để tạo hình dạng chính xác cho khoang vỉ. Trạm này có thể tạo ra diện tích đúc tối đa 350mm x 160mm với độ sâu lên đến 40mm.

3. Cắt khuôn vỉ: Sau khi tạo hình, tấm vỉ được chuyển đến trạm cắt khuôn. Tại đây, một máy ép khuôn sắc bén sẽ cắt từng vỉ riêng lẻ từ tấm nhựa chính với độ chính xác cao.

4. Thu gom phế liệu: "Mạng" nhựa còn sót lại hoặc vật liệu phế liệu sẽ được tự động cuộn vào cuộn thu gom để dễ dàng xử lý, giúp khu vực sản xuất sạch sẽ và hiệu quả.

5. Vị trí sản phẩm trên bàn xoay: Các vỉ đã cắt sau đó được chuyển đến bàn xoay sáu vị trí. Đây là trục trung tâm của máy, nơi diễn ra các bước lắp ráp tiếp theo. Một người vận hành hoặc một máy nạp tự động tùy chọn sẽ đặt sản phẩm vào các khoang vỉ.

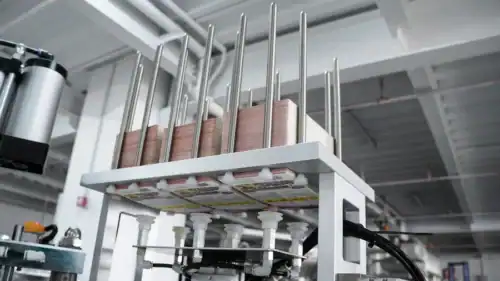

6. Tự động nạp thẻ giấy: Khi bàn xoay quay, nó sẽ đi qua bên dưới trạm thẻ giấy. Một cơ chế sẽ tự động nạp một thẻ giấy đã in từ chồng thẻ đã được nạp sẵn cho mỗi vỉ.

7. Hàn nhiệt: Sau đó, bàn xoay sẽ di chuyển vỉ chứa sản phẩm và thẻ giấy tương ứng vào trạm hàn nhiệt. Một tấm gia nhiệt sẽ ép vỉ và thẻ lại với nhau, kích hoạt lớp keo trên thẻ và tạo ra một liên kết chắc chắn, an toàn.

8. Sản phẩm đầu ra: Ở bước cuối cùng, sản phẩm được đóng gói hoàn chỉnh sẽ tự động được đẩy ra khỏi bàn xoay và lên băng tải đầu ra, sẵn sàng cho việc đóng hộp và vận chuyển. Máy có khả năng đạt công suất 15-25 chu kỳ mỗi phút.

Ra mắt Grand AC-350: Các tính năng thúc đẩy hiệu quả và chất lượng

Grand AC-350 không chỉ là một loạt các bước; nó là một hệ thống thông minh, tích hợp nhiều tính năng được thiết kế để mang lại hiệu suất, độ tin cậy và dễ sử dụng.

Hệ thống truyền động cơ học mạnh mẽ và lực kéo servo: Máy được chế tạo dựa trên hệ thống truyền động cơ học CAM đáng tin cậy, kết hợp với hệ thống kéo servo. Sự kết hợp này đảm bảo cấu trúc hợp lý, vận hành đơn giản nhưng cực kỳ chính xác, và màng phim được kéo qua máy với độ căng đồng đều, chính xác, yếu tố then chốt cho chất lượng tạo hình.

Điều khiển PLC thông minh: Trung tâm của AC-350 là hệ thống PLC (Bộ điều khiển logic lập trình). Bộ não trung tâm này đồng bộ hóa mọi hoạt động và cho phép điều khiển tốc độ tần số có thể điều chỉnh. Kết quả là tiếng ồn vận hành giảm đáng kể và độ ổn định tổng thể của máy được nâng cao đáng kể.

Nâng cao an toàn vận hành: An toàn là ưu tiên hàng đầu. AC-350 được trang bị hệ thống điều khiển quang điện và hệ thống phát hiện tự động. Các cảm biến này giám sát quy trình làm việc, phát hiện bất kỳ bất thường nào và dừng máy nếu cần thiết, nhờ đó nâng cao an toàn cho người vận hành.

Thay đổi khuôn nhanh chóng và dễ dàng: Sản xuất hiện đại đòi hỏi sự linh hoạt. AC-350 được trang bị thiết kế định vị mô-đun cho khuôn. Điều này cho phép người vận hành thay đổi khuôn nhanh chóng và dễ dàng, giảm thiểu thời gian chết khi chuyển đổi giữa các thiết kế bao bì sản phẩm khác nhau.

Vệ sinh và thẩm mỹ vượt trội: Toàn bộ máy được bao bọc trong lớp vỏ bảo vệ bằng thép không gỉ. Điều này không chỉ mang lại vẻ ngoài sạch sẽ, chuyên nghiệp cho máy mà còn giúp việc vệ sinh và bảo trì máy trở nên cực kỳ dễ dàng, giúp nâng cao chất lượng sản phẩm và đáp ứng các tiêu chuẩn vệ sinh công nghiệp.

Thông số kỹ thuật tổng quan

Vị trí xả chất thải của máy đóng vỉ

Đối với những ai cần thông tin chi tiết, sau đây là các thông số kỹ thuật chính của mẫu AC-350:

Năng lực sản xuất: 15-25 chu kỳ/phút

Vật liệu đóng gói: PVC/PET (0,18-0,5mm x 350mm)

Diện tích bìa cứng tối đa: 400mm x 200mm

Diện tích và độ sâu tạo hình tối đa: 350mm x 160mm x 40mm

Tiêu thụ điện năng: 380V 50Hz, 13kw

Kích thước máy (Dài x Rộng x Cao): 3700 x 2500 x 1700 mm

Trọng lượng máy: 2000kg

Kết luận: Đầu tư thông minh cho bao bì chuyên nghiệp

Grand AC-350 Giấy-Nhựa Máy đóng gói vỉ Không chỉ là thiết bị; AC-350 là giải pháp toàn diện cho các doanh nghiệp muốn nâng cao sức hấp dẫn của sản phẩm trên kệ hàng đồng thời tinh giản quy trình sản xuất. Bằng cách kết hợp tự động hóa tốc độ cao, điều khiển PLC thông minh và các tính năng thân thiện với người dùng, AC-350 mang lại sự nhất quán, độ tin cậy và khả năng hoàn vốn đầu tư nhanh chóng. Dù bạn đóng gói dụng cụ, mỹ phẩm, văn phòng phẩm hay pin, AC-350 đều cung cấp sức mạnh và độ chính xác cần thiết để nổi bật trên thị trường cạnh tranh khốc liệt.