The Ultimate Guide to Blister Packaging

8 Factors You Should Consider Before Buying a Capsule Filling Machine

10 Reasons Why You Should Own a Grand Capsule Filling Machine

As people become more health-conscious, they need more supplements, vitamins, and pharmaceutical products. They also want these products to come in capsule form, which is easy to use. No matter if you are a seasoned maker, someone new to the market, or a solo company, you would be able to make high-quality capsules quickly enough to stay in business. In this case, capsule-filling tools are very helpful.

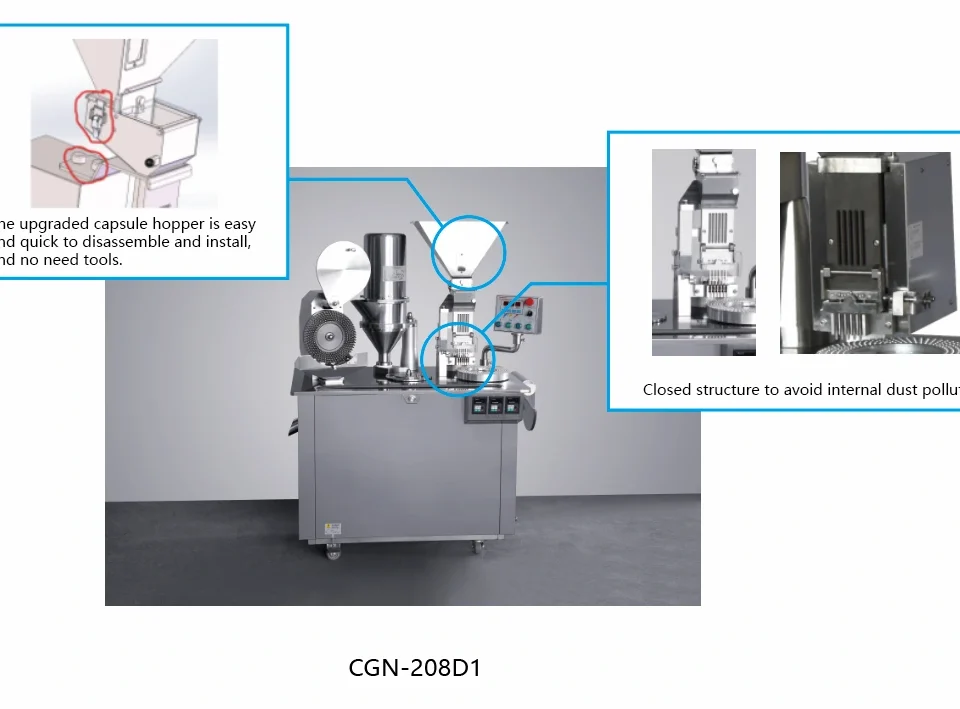

There are a lot of different kinds of capsule filling machines. The Grand Capsule Filling Machine is one of a kind because of how well it works and how well it is built. Getting this machine to help them make more is an investment, but it's more than that. In fact, it's a step toward making your business more reliable, accurate, and able to keep growing. We have put together a list of 10 strong reasons why you should buy a Grand Capsule Filling Machine.

1. Unmatched Durability and Longevity

When people buy heavy-duty tools, the first thing they think about is how long they will last. Grand Capsule Filling Machines are built to last, so they save you money in the long run. A lot of good materials go into making each machine, like stainless steel that doesn't rust, high-quality plastics, and precision-machined parts. These materials are strong and can take the wear and tear of daily life. They also keep their shape over time, even in less-than-ideal circumstances.

Also, important parts of the machine are hard-anodized to make them last longer. By making this change, the machine will last for many years without needing to be fixed or changed very often. That means businesses will have less downtime and service breaks, and they will get more work done. Because the machine is so big, you have to keep things on track all the time, even when you're working with rough powders in damp places.

2. Strict Compliance with Regulatory Standards

There are very strict rules about quality and safety that must be followed when it comes to pharmaceuticals and vitamins. The Grand Capsule Filling Machines are great for these tasks because they are well-made. They have papers that show they follow world rules like GMP and cGMP. This makes sure that the tools always make pills that are clean, safe, and up to par.

Not only that, but the tools have the CE mark, which means they meet the strict EU rules for health, safety, the environment, and other things. This means that companies can sell their goods anywhere without having to think about the law. When a company wants to ship its goods, the Grand Capsule Filling Machines formal deal helps them make sure the goods are of the best quality and speeds up the process.

3. Precision Filling for Consistent Quality

The accuracy needed in capsule production is critical. Even a slight misalignment can result in product waste or customer dissatisfaction. Precision is the main selling point of Grand Capsule Filling Machines, making sure that each capsule filled contains the correct dosage.

Here’s how different types of machines perform in terms of accuracy:

- Manual Machines: ±2–3%

- Semi-Automatic Machines: ±1–2%

- Fully Automatic Machines: ±0.5% or better

Achieving such precision also minimizes errors and ensures that your product meets the highest quality bar so that you do not compromise trust with your customers.

4. High Efficiency Across All Production Levels

One more thing that the Grand Capsule Filling Machine line can do is meet a lot of different needs for products of all kinds, from small to large. Yes, you can always find a plan that works for you, no matter what kind of business you run or how big it is (like a drug company). The production capacity of fully automated machines is a substantial 450,000 capsules per hour. At most, 200 capsules can be made by automatic tools every hour.

This makes sure that the tools can grow with your company. A small company can start with a machine that is manned or partly automated and then move up to one that is fully automated as their output needs increase. For example, manufacturing companies gain from these kinds of tools because they cut down on the time it takes to do a job and make the company more efficient.

5. Modular Design for Flexibility and Customization

Flexibility is the key to modern production, and it is also found in the design of Grand Capsule Filling Machines. The parts that make up each machine can be switched out and put together, taken apart, or changed readily. This style has a number of benefits:

- Simplified Maintenance:The parts themselves can be swapped out fast, thus limiting downtime and its associated repair costs. You don’t need to replace the whole machine for small issues.

- Adaptability:Different modules can be used to handle capsule sizes, types, and production. It’s versatile whether you’re filling gelatin capsules or plant-based ones, and it adapts effortlessly.

- Future-Proofing:The more advanced the technology, the more you can integrate new components or replace existing ones without acquiring a new piece of equipment. It stretches to prolong the life of the machine and also guarantees your investment is still valid.

This flexibility reduces the time it takes for manufacturers to adjust to changing market trends and keep production processes consistently in motion.

6. User-Friendly Design for Hassle-Free Operation

To some people, it might be scary to operate large and complicated machines, but Grand Capsule Filling Machines are friendly to operate. These machines are convenient for any user, be it a first-time user, because they embrace comfort and at the same time come with instructions on how they are used.

Transport control models come with Programmable Logic Controller (PLC) & Human-Machine Interface (HMI) systems integrated into them. These systems help in control and tracking. Real-time management creates an ability for the workers to adjust some parameters, monitor production data, and solve some issues. The tools also include directions and training that allow the beginners to get familiar with their operation in a short time.

This design will help businesses spend less time training the staff, avoid more mistakes, and improve the production process.

7. Cost-Effective Investment with High ROI

Investing thousands in a Grand Capsule Filling Machine is not only cost-effective, but it’s also an investment that reaps huge profits in the long run. One may find the machine a bit costly initially, but the money anyone will save from such a machine is worth the cost of that machine.

These tools help save money in the following ways:

- Reduced Labor Costs:This process can also be automated, resulting in the manual effort involved in filling the capsules and using them for other tasks.

- Minimized Wastage:Accurate filling guarantees optimum usage of the raw materials in the production process, little wastage, and high returns.

- Lower Maintenance Expenses:The design and construction are strong, so it can adapt in case of any change. Also, the maintenance costs are cheap. While construction of the new one takes time, the operations are not interrupted.

Mechanically, these factors are combined to give a high return on investment, making it a cost-effective solution for businesses wanting to get the most profit from their crop.

8. Seamless Integration with Production Lines

Efficiency in a modern manufacturing environment is regularly determined by the degree to which certain pieces of equipment work with one another. Designed to integrate seamlessly with other line equipment, including capsule polishing machines, packaging systems, and quality control devices, Grand Capsule Filling Machines are available as modular open systems that can be constructed on walls or wheeled into place.

These advanced PLC systems facilitate perfect communication between machines and, therefore, provide synchronized operation for maximum efficiency. The compatibility helps to reduce bottlenecks, increase workflow, improve company productivity, and ensure that companies constantly meet production targets.

9. Reliable Customer Support and Comprehensive Training

More than equipment, a Grand Capsule Filling Machine is backed by a great team of professionals who are dedicated to your success. If you invest in one of these machines, you will get round-the-clock technical support to fix any problems right away.

The company also provides complete training courses to assist users in maximizing machine performance. Everything from the basics of how to use it up through the really serious troubleshooting is covered, leaving users no excuses for not getting every bit out of their equipment possible. Added to this peace of mind is a good warranty, which covers repairs and replacements as needed.

10. Environmentally Conscious Manufacturing

Today, sustainability is becoming an increasingly important part of manufacturing. With eco-friendly principles, Grand Capsule Filling Machines are approached with an energy-efficient system that consumes less power. The built-up design reduces the wastage of resources through repair and improvement rather than a complete replacement.

For environmentally-conscious organizations, these machines are focused on ensuring environmental conservation in production, which is in line with efforts by various countries trying to minimize industrialized waste and energy consumption.

Conclusion

A Grand Capsule Filling Machine is needed whether you are producing medicines, vitamins, or health products. It is highly recommended for anyone who needs to switch between production for its durability, accuracy, speed, and versatility.

These tools provide a one-stop solution to all current industry concerns, from the management and enforcement of rules to reduced costs and going green. It is not just wise to invest in a Grand Capsule Filling Machine but also an intelligent decision to acquire one for your business.