Capsules vs Tablets: Which is Right for You?

Grand Participates in ALLPack Indonesia EXPO 2024 to Develop New Opportunities

5 Tips to Buy a Semi-Automatic Capsule Filling Machine

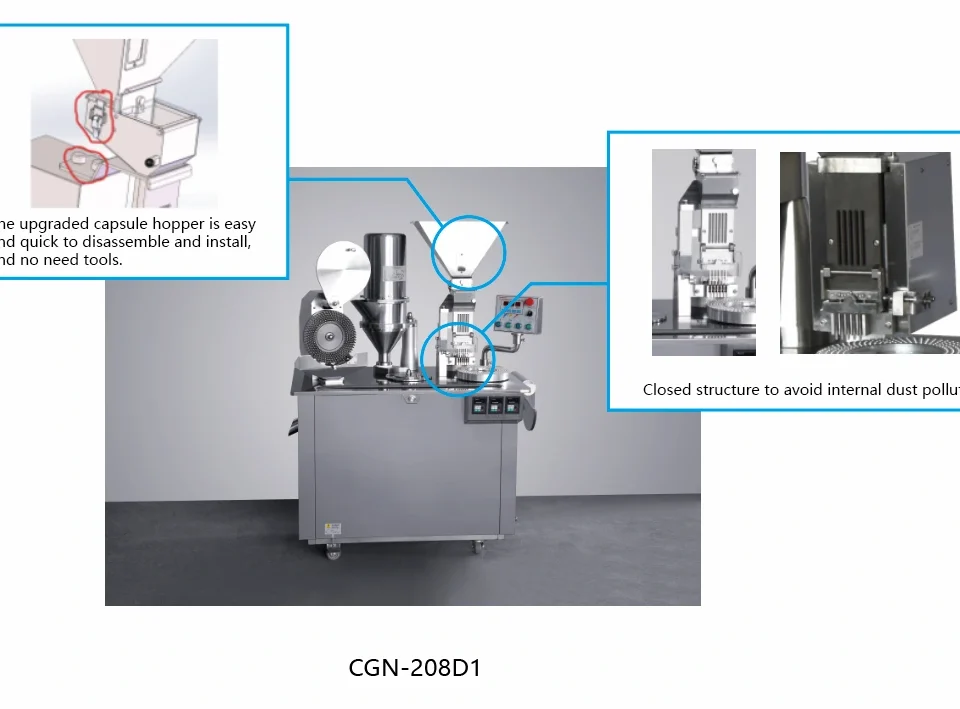

Buying a semi-automatic capsule filling machine is a big decision for businesses. It can increase your production, save a lot of time and make you more productive. This machine gives both some automation and some manual control, great for making medicines, supplements, or food. There are five basic steps that you should follow to make sure you buy the most appropriate machine.

1. Know Your Production Needs

Buyers of a semi-automatic capsule filling machine must know how much it can produce. Consider how many capsules do you want to be filled per day or per month. Semi-Automatic Machines made by Grand Pack can fill 25000 – 50000 capsules in an hour.

If your business is growing, choose a machine that can handle more production in the future. If you’re filling 10,000 capsules now and expect to do ten times more soon, buy a machine with enough capacity. In this way, you will not have to upgrade anytime soon which will help minimize the costs in the long term.

2. Verify Compatibility With Different Capsule Sizes

There may be variations in capsule sizes depending on the products. Ensure the equipment you select will accommodate the sizes needed. As for our machines at Grand Pack, these can fill capsules with a size range from #000 to #4.

If you intend to manufacture products of different sizes at a time, then look for a machine which will have interchangeable tooling. This means you can switch between sizes without buying a new machine. This ability will help you to save money and space.

If you are now filling #1 size capsules but want to add #00 or #4 sizes in the near future, it is advisable to go for a machine that can fill different sizes with ease.

3. Go for a Machine Produced with High Standards

A good-quality machine will last longer and work better. Semi-automatic stainless steel machines tend to be more efficient as they are more durable, easily cleaned, do not rust or get contaminated. This is especially important in the case of companies whose business is within pharmaceutical or food industry where sanitary concerns are the order of the day.

In my company Grand Pack, all the machines are made of stainless steel which is of high quality passed through necessary industry requirements. This makes your machine remain in good condition for a long time and also help in cost reduction on maintenance. An accurately built machine also guarantees that the filling of your capsules is done top to bottom with precision.

4. Seek the Things Which are Easy to work with

It must be easy to operate Your machine. If it is too complex, there is bound to be lots of delays and production hitches. The decision on which machines to purchase should be determined by smooth operational features. When making the machines at Grand Pack, we always strive to make them easy to use even for people who have never operated such machinery.

Some machines have inbuilt features like loading and aligning capsules and they help to cut the time and physical labor required to perform those tasks. These features ensure that your production process is streamlined and made more efficient.

Buy a machine that will be easy to clean. This will ensure that there are no delays and interruptions while switching batches or products.

5. Focus on Aftersales Support and warranty

A machine is not purchased for only one time use, therefore there is a need for attention towards after sale help. Even the most effective devices will require some service outages for repairs or replacement of parts. Other than that, make sure that you work with a supplier who has excellent after sales service.

In case you need repair or replacement, Grand Pack offers fast replacement or repair services. In addition, try to get guarantees on the machines. This provides you with reassurance and coverage for your money should anything go wrong.

Here are some common questions that might be included in the FAQ for 5 Tips to Buy a Semi-Automatic Capsule Filling Machine

In what fundamentals structural and functional aspect a semi-automatic differs from fully automatic?

A semi-automatic machine requires some generation of work like insertion of capsules while a fully automatic machine does everything and anything for you regarding insertion. Semi-automatic machines are preferred for medium scale production because they are cost-effective, and still offer some level of flexibility over the process.

Does a semi-automatic machine work with multiple sizes of capsules?

Yes many semi-automatic machines enveloping granules, like the Grand Pack ones, come with additional parts that fill multiple capsule sizes. This is useful if you handle several systems differing in the capsule size.

How much is the maintenance required for a semi-automatic machine?

You will need to make sure that you clean it at regular intervals and make general inspections for wearing parts. It is not so complicated to operate machines from Grand Pack, and if some parts have to be replaced, we will provide the help and parts due to the warranty.

Is it hard to get acquainted with a semi-automatic capsule filling machine?

No, the design of semi–automatic machines is such that simple operation is possible. Machines supplied from Grand Pack have this as an assurance that they are not complicated to use and in that regard training of fresh employees does not take long.

How can I determine whether a semi-automatic machine will be suitable for my business?

When the production is too high to be done with manual filling and not yet enough to require a fully automatic machine, a semi-automatic model is an appropriate choice. It enables you to produce more than in manual ways, without spending too much on fully automatic systems.