Pill counter machine – Pharmaceutical Best Accuracy

Your Guide to Choosing the Right Tablet Press Machine

Blister Packaging: A Perfect Fit for the Cosmetics Industry

Introduction

Blister pack design has come a long way since its pharmaceutical origins, and today it’s a cornerstone of cosmetic blister packaging solutions. By sealing products between a clear plastic dome and a sturdy backing card or foil, a blister pack not only showcases cosmetics like lipsticks and eyeshadows but also protects them from moisture, dust, and damage. With consumers demanding both safety and style, modern blister packs balance functionality and visual appeal, while high-efficiency machines such as the Grand Blister Pack Machine ensure production lines keep pace with market needs.

Grand blister card packaging machines-DGX-380

Evolution of Blister Pack Technology

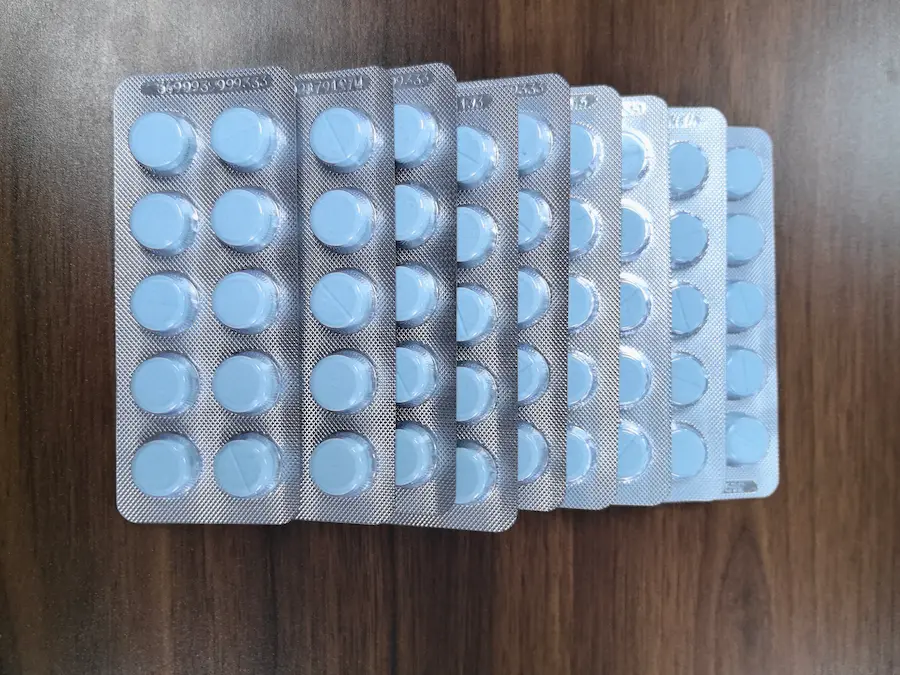

Originally, blister packs served pharmaceutical needs—tablets, capsules, and suppositories benefited from tamper-evident seals and clear visibility.

According to the Journal of Packaging Science, transparent packaging reduces product returns by up to 15% since customers can inspect items before purchase¹. As the industry shifted, manufacturers applied the same principles to cosmetics: Alu PVC blister pack films now offer barrier protection against oxygen and UV light, preserving delicate formulas.

Why Blister Packs Shine in Cosmetics?

Cosmetic products face unique challenges: creamy foundations separate, powdered eyeshadows crumble, and lip glosses suffer oxidation. A well-engineered blister pack isolates each unit, preventing cross-contamination and air exposure.

Users appreciate the single-serve access—when you pop out one palette segment, the rest stay sealed and pristine. Blister packs also deliver “first-use freshness,” which builds brand trust. In addition, printed backing cards allow vibrant graphics and ingredient call-outs, enhancing shelf impact.

Customization and Branding Opportunities

Modern blister pack production goes beyond simple thermoforming. Brands leverage digital printing to apply full-color logos and patterns directly onto the backing card or foil. Embossed textures and spot-UV accents further elevate the unboxing experience. For clean-beauty lines, foil seals can display “100% recyclable” or “BPA-free” badges—key selling points that drive purchase decisions. Long-tail phrases such as “eco-friendly cosmetic blister packaging” rank well with consumers who value sustainability. According to Cosmetics Packaging Insights, over 60% of beauty buyers consider packaging recyclability in their buying process², making these customizations more than just marketing—they’re revenue drivers.

High-Efficiency Machinery: The Grand Advantage

Behind every flawless blister pack is a reliable machine. The Grand Blister Pack Machine, including the flagship Blister Alu PVC Packaging Machine 270, delivers exceptional speed and precision. Capable of running at 300 cycles per minute, the DPP-270 minimizes downtime with its quick-change tooling and automated defect detection. Integrated touchscreen controls let operators switch between 10 mL ampoules, 5 mL vials, and compact cosmetic palettes in under 15 minutes. Grand’s modular design supports additional stations—labeling, cold sealing, and batch-coding—without major overhauls. For brands aiming to scale, this level of flexibility and consistent quality is invaluable.

Ensuring Quality and Compliance

Cosmetic blister packaging isn’t just about looks; it must meet regulatory standards. Machines like the Grand DPP-270 include CIP (Clean-In-Place) systems and HEPA-filtered enclosures for Class 100 (ISO 5) cleanroom operations. Real-time monitoring tracks seal integrity and film tension, reducing scrap rates to below 2%. Such data-driven quality control aligns with FDA and EU cosmetics regulations, giving quality teams the documentation they need.

Maximizing ROI with Blister Pack Automation

Investing in a blister pack machine DPP-270 or comparable Grand system pays dividends through reduced labor costs, lower material waste, and higher line throughput. A case study from Beauty Tech Review found that switching from semi-automated to fully automated blister packaging cut per-unit labor by 45%³. Additionally, precision filling and sealing reduce product loss, ensuring every gram of lipstick or face serum reaches the consumer. When planning your next line upgrade, look for machines with predictive maintenance alerts and remote diagnostics—features now common on Grand’s platform. These smart capabilities minimize unexpected shutdowns and help you meet tight launch deadlines.