آلة غربلة الأدوية الكبرى: الحل الأمثل لإزالة الغبار وتلميع الأقراص

في إنتاج الأدوية والمكملات الغذائية الحديثة، تُعدّ جودة الأقراص وكفاءة العملية أمرًا لا غنى عنه. جراند آلة الغربلة تم تصميم السلسلة لتكون الأفضل على الإطلاق آلة مساعدة لضغط الأقراص، يجمع بين الرفع وإزالة الغبار والتلميع في وحدة واحدة موثوقة. هذا آلة غربلة دوارة للأعلى يتكامل بسلاسة مع معداتك الحالية، بما في ذلك أي مكبس أقراص أوتوماتيكي بالكامل وكاشفات المعادن، لإنشاء خط إنتاج مبسط وفعال ومتوافق مع معايير التصنيع الجيدة (cGMP).

مقدمة لسلسلة آلات الغربلة الكبرى

الميزات والمزايا الرئيسية

تم تصميم آلاتنا باستخدام التكنولوجيا المتقدمة لتقديم أداء وموثوقية لا مثيل لها.

✅مسار إزالة الغبار الموسع: بفضل مسارها الحلزوني الطويل (حتى 7.5 متر)، تضمن آلتنا تقليب الأقراص وتلميعها بلطف على جميع الجوانب للحصول على لمسة نهائية فائقة.

✅غربلة عالية الكفاءة: يضمن التصميم المبتكر إزالة الغبار والتلميع بشكل فعال دون التسبب في أي ضرر أو تقطيع أو تشقق للأقراص.

✅التحكم في السرعة القابلة للتعديل: يمكنك بسهولة مطابقة سرعة مزيل الغبار مع مخرجات مكبس الكمبيوتر اللوحي الخاص بك للحصول على سير عمل سلس ومستمر.

✅إمكانية التعديل بزاوية 360 درجة: يمكن تدوير منافذ الدخول والخروج بزاوية 360 درجة كاملة، مما يوفر أقصى قدر من المرونة لتناسب أي تخطيط إنتاج.

✅متوافق مع معايير التصنيع الجيدة (GMP): مُصمم لسهولة الفك والتنظيف دون أي زوايا غير ظاهرة. جميع أجزاء التلامس مصنوعة من مواد عالية الجودة ومقاومة للتآكل.

التطبيقات الأساسية

تُعد آلة الغربلة الكبرى قطعة حيوية من المعدات لمجموعة واسعة من الصناعات التي تتطلب تشطيبًا دقيقًا للأقراص:

المستحضرات الصيدلانية: لإزالة الغبار وتلميع جميع أنواع الأقراص، من الأقراص غير المغلفة القياسية إلى الأقراص الفوارة والقابلة للمضغ.

المواد المغذية: مثالي للفيتامينات والمعادن والمكملات العشبية حيث يكون المظهر النظيف والاحترافي أمرًا بالغ الأهمية.

الأغذية والحلويات: مثالي لإنتاج أقراص الحلوى النظيفة والمصقولة والنعناع ومنتجات غذائية مضغوطة أخرى.

الهندسة الكيميائية: مناسب لإزالة الغبار من المحفزات المتخصصة والمنظفات والمساحيق المضغوطة الأخرى.

الميزات الرئيسية لآلة غربلة الحبوب

تتضمن آلتنا العديد من الميزات المتقدمة، بما في ذلك:

- مدخل ومخرج قابلان للتعديل بزاوية 360 درجة لتسهيل التوافق مع آلات التعبئة ومعدات الإنتاج الأخرى.

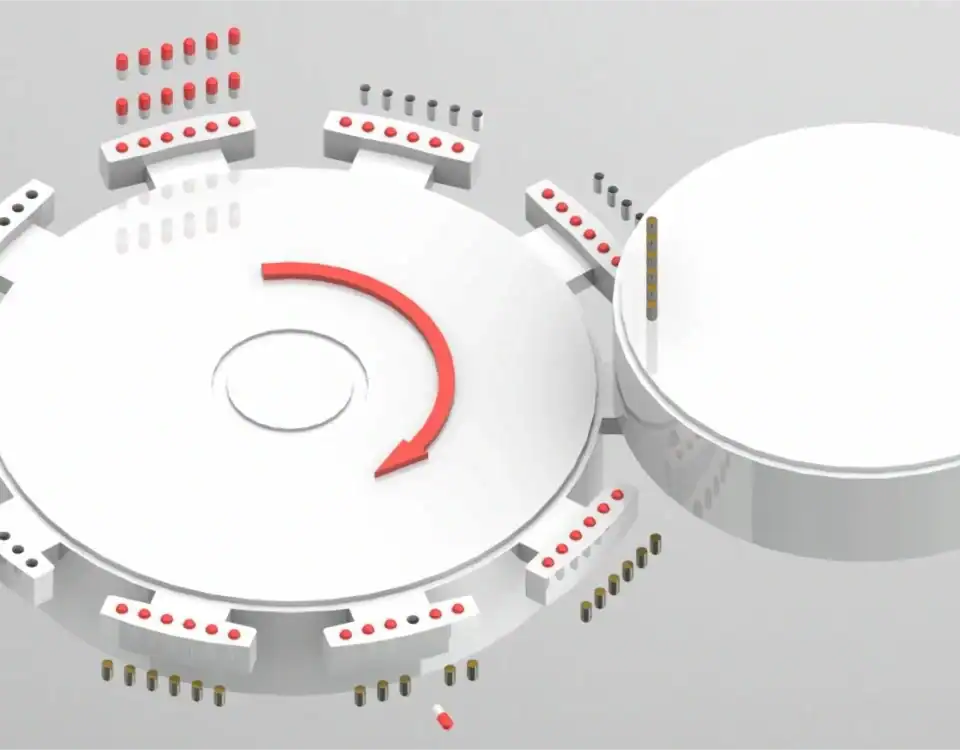

- آلية الفرز التلقائي الذي يميز بين الكبسولات التي تحتوي على محتويات، والأصداف الفارغة، والحطام، والأجسام المنقسمة.

- تصميم سريع التعبئة لتسهيل التفكيك والتنظيف، مما يقلل من وقت التوقف أثناء الصيانة.

- أجزاء اتصال من الفولاذ المقاوم للصدأ (316L) التي تلبي معايير تصنيع الأدوية الحديثة، وتضمن المتانة والسلامة.

- نظام تنظيف متوافق مع ممارسات التصنيع الجيدة (GMP) بدون أي نهايات مسدودة، مما يدعم الصرف الصحي الشامل.

- نظام جمع الغبار للحفاظ على بيئة إنتاج نظيفة.

مقارنة المعلمات

| المعلمة | جراند SZS230 | جراند SZS750 |

|---|---|---|

| نموذج | SZS230 | SZS750 |

| الحد الأقصى للإنتاج (أقراص/ساعة) | ~1,000,000 (لـ Ø4 مم) | ~3,000,000 (لـ Ø5 مم) |

| مسافة إزالة الغبار | 6.2 متر | 7.5 متر |

| الحد الأقصى لقطر الجهاز اللوحي | Φ20 مم | Φ25 مم |

| مزود الطاقة | 110 فولت/220 فولت، 50/60 هرتز | 110 فولت/220 فولت، 50/60 هرتز |

| قوة | 150 واط | 300 واط |

| مستوى الضوضاء | <75 ديسيبل | <75 ديسيبل |

| الأبعاد (مم) | 500×550×(1350-1500) | 480x480x(1445-1640) |

| وزن | 75 كجم | 80 كجم |

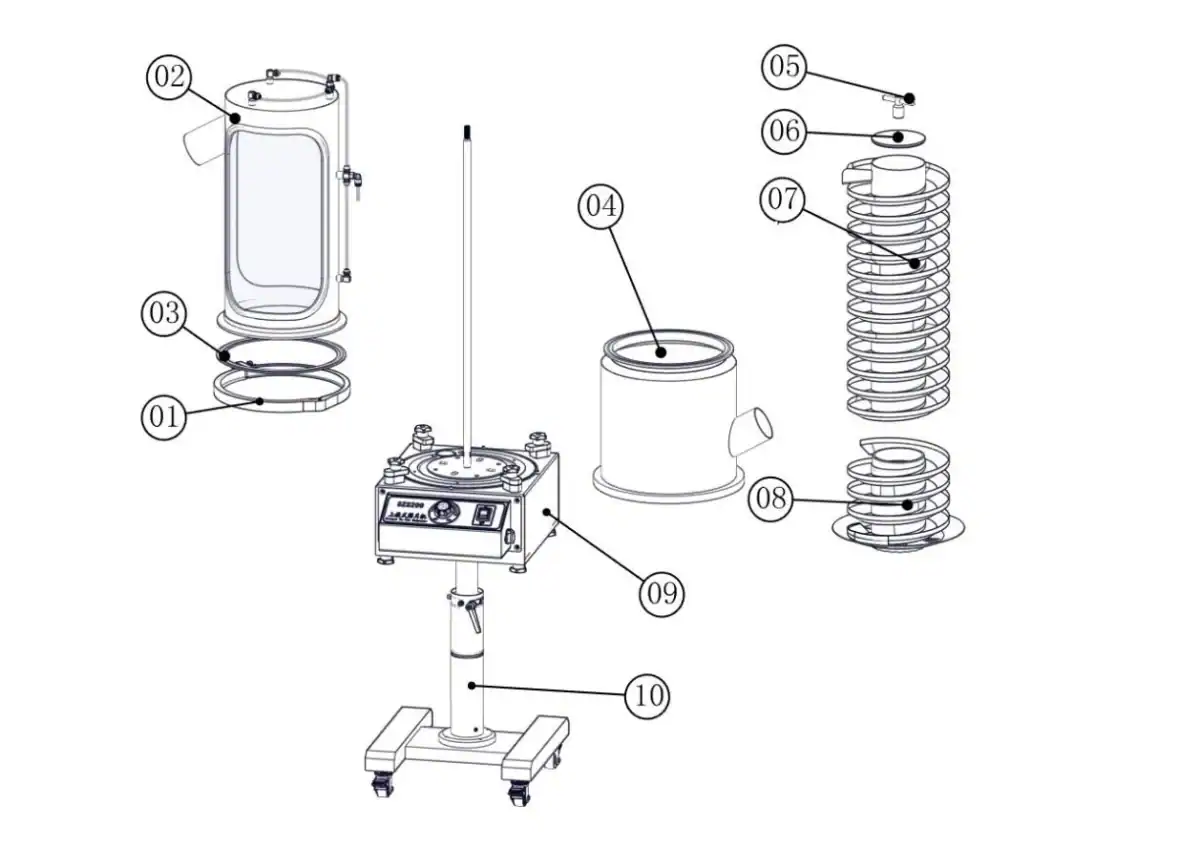

01 المشبك

02 الجزء الثاني من الجسم

حلقة الختم 03

04 الجزء الأول من الجسم

مقبض متقاطع 05

لوحة ضغط 06

07 الجزء الثاني من شبكة الغربال

08 الجزء الأول من شبكة الغربال

09 صندوق كهربائي، محرك و

التحكم في مصدر الطاقة

10 أعمدة صاعدة وهابطة

الهيكل والتصميم المتقدم

كل مكون من مكونات جراند آلة الغربلة تم تصميمه ليكون آمنًا، ومستقرًا، وسهل الاستخدام.

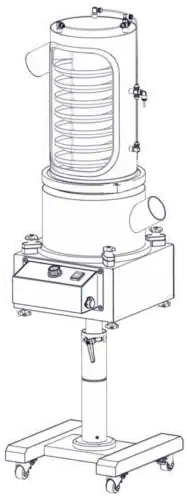

منصة التشغيل المحمولة: هيكل متين مزود بعجلات قابلة للقفل يضمن أقصى قدر من الثبات أثناء التشغيل وسهولة الحركة عند الحاجة. يتيح الإطار القابل لتعديل الارتفاع توافقًا مثاليًا مع الآلات الأخرى.

هيئة العمل الرئيسية: قلب الآلة هو جسم الاهتزاز، الذي يُشغّل مسار إزالة الغبار الحلزوني. تتصل لوحة تجميع الغبار المدمجة ومنفذ التفريغ بنظام تفريغ خارجي لإزالة جميع المسحوق المتساقط بكفاءة.

الغطاء الخارجي المغلق: حجرة مغلقة بالكامل مزودة بنافذة مراقبة تمنع التلوث المتبادل، وتتيح مراقبة آمنة للعملية بأكملها. صُممت هيكلية الجهاز لسهولة الفك دون استخدام أدوات، مما يجعل التنظيف سريعًا وبسيطًا.

هل أنت مستعد لرفع إنتاج جهازك اللوحي؟ اتصل بنا للحصول على عرض أسعار اليوم!

تفاصيل الماكينة في التركيز

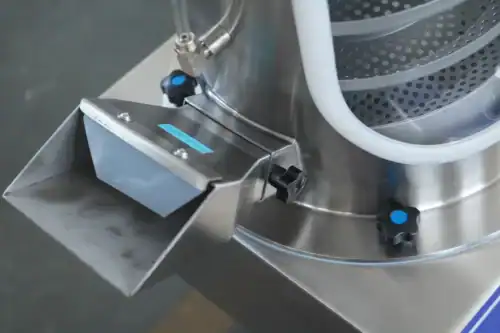

مخرج ماكينة الشاشة

مقبض التحكم في ماكينة الغربلة

القرص الداخلي للشاشة

منفذ تغذية آلة الشاشة