Liquid Capsule Filling Machines

Liquid Capsule Filling Machine offer precise, efficient, and ideal for pharmaceutical liquid encapsulation.

The pharmaceutical and nutraceutical industries are constantly evolving. Today, some of the most innovative and effective formulations—including high-activity compounds, poorly soluble drugs, and hot-melt suspensions—are best delivered in a liquid or semi-liquid form. However, filling these substances into hard capsules presents a unique set of engineering challenges. It demands precision, speed, and an absolutely perfect seal.

Precision Liquid Capsule Filling Machine Solutions

Grand Machinery is at the forefront of this technology. We have independently researched and developed a world-class portfolio of capsule filling machine models designed specifically for this purpose. As a Liquid capsule filling machine pioneer, we hold multiple technology patents for our innovative systems, which are already in use by pharmaceutical and healthcare companies worldwide.

Contact Us

Develop Your Business with Grand

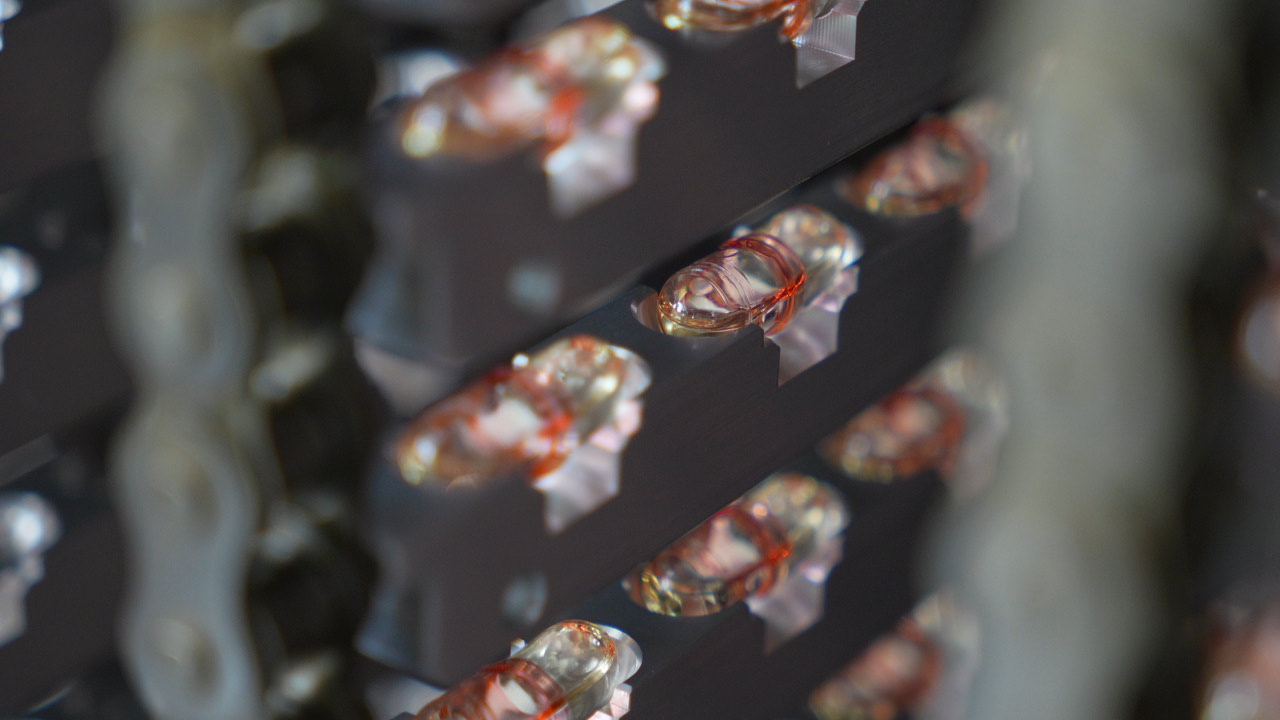

Intelligent Fiber-Optic Detection System

To ensure stable production and zero waste, our machines are equipped with high-speed, high-resolution fiber-optic sensors.

These sensors perform non-contact detection to check if a capsule has separated correctly.

If an un-separated capsule is detected, the system instantly sends a signal to the filling station to stop the liquid filling for that position. The machine then automatically ejects the defective capsule at the rejection station.

Features:

The Best Accuracy with Precision Filling

Rest easy with our machines, precise to within ±2%, using peristaltic or ceramic pumps. Sensors detect minute variations in filling volume, even outside controlled lab conditions.

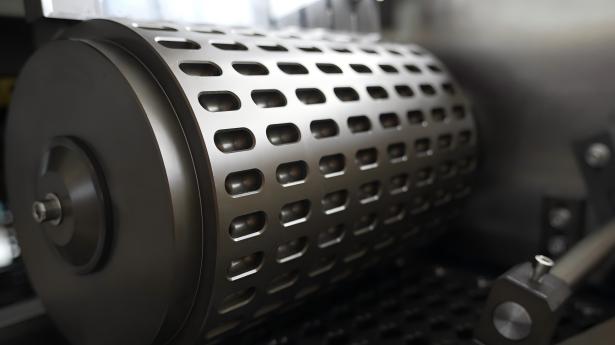

Smooth Capsule Loading

Now with vacuum positioning and fiber-optic sensors for over 99% efficiency in capsule loading. Responds in real-time to recognize capsules missing during loading.

Fully Automated:

Our fully autonomous fillers detect missing parts with alerts, allowing you to focus on what matters. They work independently, ensuring smooth and seamless operation.

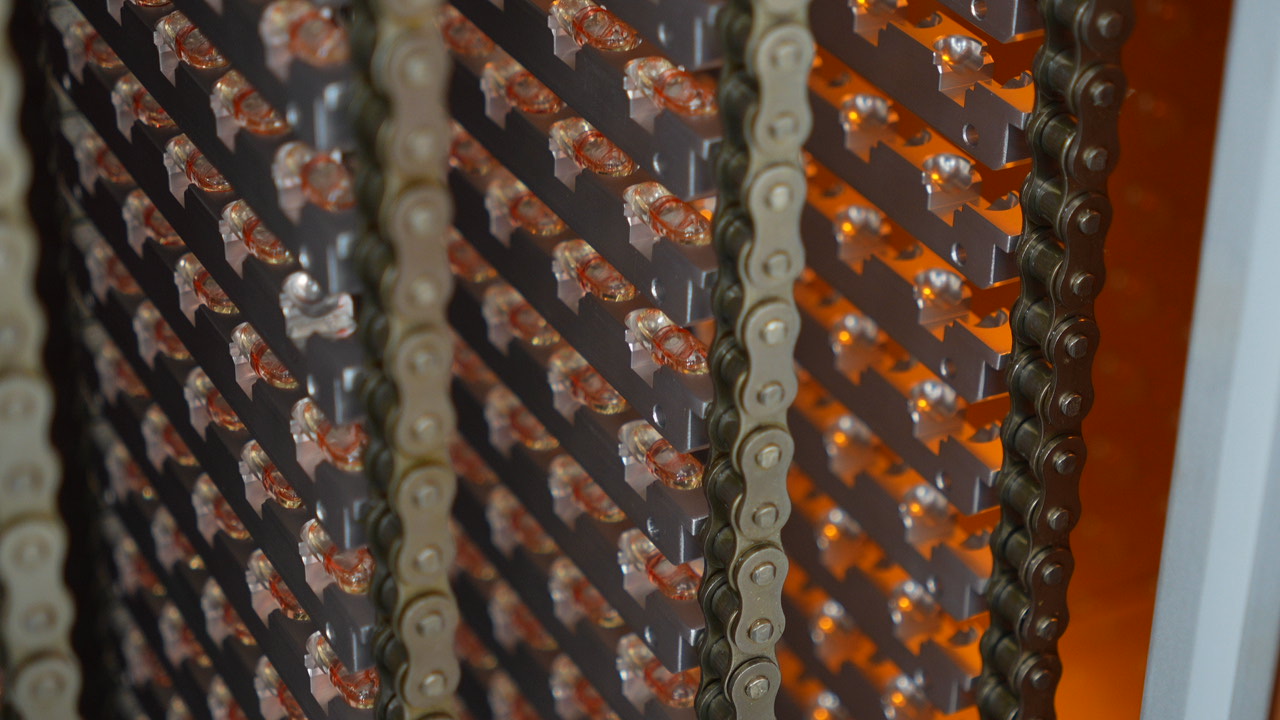

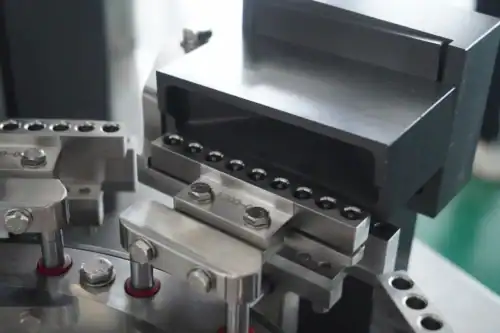

Superior Sealing with Adjustable Rollers

Adjustable servo motor controlling 2x sealing rollers with on demand differential pressure to prevent fill from leaking out, and fully encapsulate.

Why Choose Us

Extensive Scale to Match Production Demands

We have a 50,000 sq. meter facility with filling lines, offering serious production capacity and high daily machine output.

Timely Delivery You Can Depend On

With realistic timelines tailored to your needs, we ensure on-time delivery of your capsule filling machine. Our simple, efficient systems help you plan with confidence.

Rigorous Quality Control

We use top-quality components from world-renowned manufacturers, with each rigorously tested before assembly, resulting in a highly reliable encapsulation machine.

Maximum Efficiency and Output

Eliminate waste and maximize speed with our streamlined design. Upgrade your encapsulating capabilities today.

Video Gallery

How does a semi-automatic hard capsule sealing machine work?

Fills liquid into capsules with precision and efficiency.