Vial Filling Machines: Key to Combating Antibiotic Resistance

Infusion bag filling machines are inseparable from modern medical care

The Essential Role of Cartoning in Pharmaceutical, Food, and Household Packaging

In today's competitive market, packaging is crucial not just for protection but also for creating a compelling consumer experience. Whether it's medicine boxes, food packaging, or household products, the way a product is packaged influences both its marketability and its ability to protect its contents. Cartoning has become an indispensable process in modern manufacturing, ensuring products are securely packed and ready for distribution.

The application of box packaging covers medicine, daily chemicals and food

The application of box packaging covers medicine, daily chemicals and food

In this blog, we will explore the importance of cartoning in various industries, focusing on its role in pharmaceutical, food, and personal care packaging, and how advancements like vertical cartoning machines are revolutionizing this process.

What is Cartoning?

Cartoning refers to the process of packaging products into cartons, which are typically made from cardboard or other paperboard materials. This process is vital in industries where both product safety and presentation are important. Cartoning machines automate this process, reducing labor costs, increasing efficiency, and ensuring that products are packed with precision. Depending on the product, cartoning can involve horizontal cartoning or vertical cartoning, each with distinct advantages depending on the type of product being packaged.

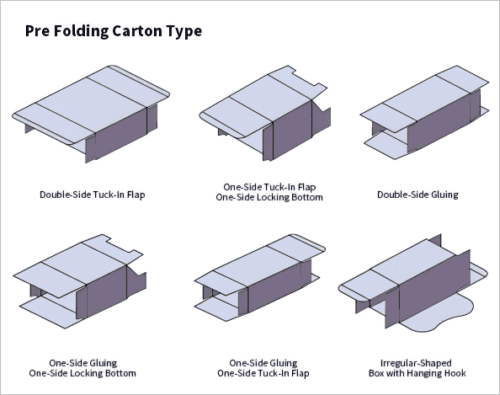

Pre Folding Carton Type

In the pharmaceutical industry, cartoning ensures that medicines are safely packaged, preventing damage and contamination during storage and transport. For food packaging, it helps in keeping the products secure while also allowing for effective marketing and branding. Similarly, in the personal care industry, cartoning protects delicate items and ensures that products maintain their integrity until they reach consumers.

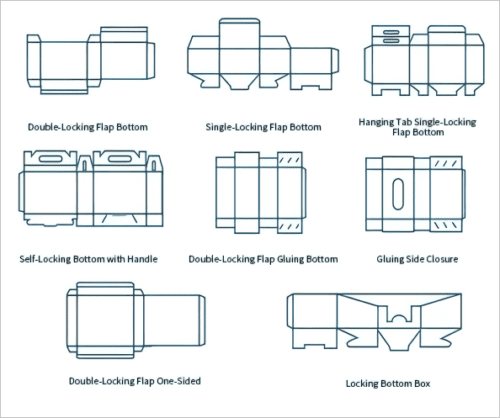

Paper box type

The Role of Cartoning in Pharmaceutical Packaging

In the pharmaceutical industry, cartoning plays a critical role in ensuring the safety and compliance of packaged medicines. Pharmaceutical packaging must meet rigorous standards, including protection against contamination, tampering, and degradation of the product. Medicine boxes are not only designed for practical purposes but also for communication, providing essential information about the drug, including dosage instructions, precautions, and manufacturing details.

The primary goal of pharmaceutical cartoning is to ensure that medicines are well-protected during their journey from the production line to the consumer. For example, blister packs containing pills or capsules are often housed in sturdy cartons that prevent physical damage and exposure to light and moisture. These protective measures are essential for maintaining the integrity of the drug and ensuring it remains effective when consumed.

Moreover, cartoning machines used in the pharmaceutical industry are designed to handle small, delicate items like vials or ampoules, requiring precise vertical cartoning solutions. This method minimizes the risk of damaging fragile products, ensuring that they remain intact throughout the packaging process.

Cartoning in Food Packaging

The food industry relies heavily on effective cartoning for both protection and presentation. Food packaging is designed to keep products fresh, prevent contamination, and attract customers with visually appealing designs. For products like snacks, beverages, and frozen foods, cartoning ensures that each item is packaged efficiently and securely.

A well-designed food carton not only protects the product but also communicates the brand's message. Cartons for food items often include vibrant colors and graphics that stand out on store shelves. The packaging must also maintain food quality by preventing exposure to light, air, and moisture, which can cause spoilage.

Cartoning machines used in the food industry are optimized for high-speed production, ensuring that large volumes of products can be packaged quickly without compromising quality. The versatility of cartoning machines means that they can handle a wide range of products, from individual snack bars to bulk food items, with the ability to adjust for different carton sizes and types.

Cartoning for Household and Personal Care Products

In addition to pharmaceuticals and food, cartoning is also essential in the packaging of household products and personal care items like soaps, cosmetics, and cleaning supplies. These products often require cartoning solutions that combine both functionality and aesthetics. For example, medicine boxes may require extra durability, while personal care packaging often includes printed designs that appeal to consumers.

Cartoning Details

Household and personal care products typically involve a horizontal cartoning process, where items are fed into the machine in a horizontal manner and packaged into their cartons. This method is ideal for products like detergents, shampoos, and other liquid or semi-liquid items. The carton not only provides protection but also helps the product stand out with attractive graphics and informative labeling.

Vertical Cartoning vs. Horizontal Cartoning Machines

When it comes to cartoning, there are two primary types of machines used: vertical cartoning and horizontal cartoning. Each type has its unique benefits depending on the nature of the product being packaged.

Vertical Cartoning Machines:

These are ideal for packaging delicate or smaller products like vials, ampoules, or pre-filled syringes. The vertical loading mechanism minimizes the risk of product damage and is perfect for items that are fragile or require extra stability.

Horizontal Cartoning Machines:

These are typically used for products like tablets, capsules, and food packaging, where items are fed horizontally into the machine. Horizontal cartoning GDZ130 is more suitable for products that can be packaged in bulk or need to be quickly processed in high volumes.

Both types of cartoning machines are essential for different stages of the packaging process, ensuring that products are safely and efficiently packed to meet industry standards.

Materials Used in Cartoning

The materials used for cartoning are typically eco-friendly and recyclable, with paperboard being the most common choice. Some common materials used in pharmaceutical and food packaging include:

Solid Bleached Sulfate (SBS) Paperboard: A high-quality material that is excellent for printing and provides

a smooth surface for vivid graphics. It is often used for food and medicine cartons due to its strength and printability.

Solid Unbleached Sulfate (SUS) Paperboard: Known for its strength and rigidity, SUS is perfect for packaging fragile items like vials and ampoules.

Clay Coated News Back (CCNB) Paperboard: This material combines strength with printability and moisture resistance, making it ideal for food packaging.

Kraft Paperboard: A sustainable material made from recycled wood, Kraft is commonly used for environmentally-conscious packaging.

Corrugated Cardboard:

Often used for bulk packaging, corrugated cardboard offers excellent protection against physical damage and is cost-effective.

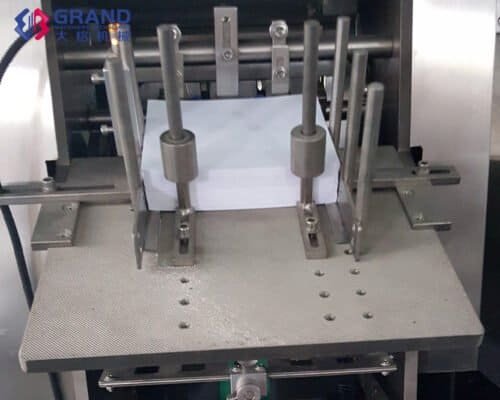

The Innovation Behind Grand’s Cartoning Machines

As the demand for efficient and reliable cartoning machines grows, Grand has introduced innovative solutions that enhance the packaging process. Their vertical cartoning machines are designed with cutting-edge technology to meet the needs of industries like pharmaceuticals and food production. With precision engineering and high-speed operation, Grand’s cartoning machines ensure that products are packed securely while maintaining production efficiency.

One of the standout features of Grand’s cartoning machines is their ability to handle a wide range of products, from delicate vials and ampoules to bulk food packaging. Their machines are designed for easy integration into existing production lines, offering both flexibility and scalability for manufacturers.

Conclusion

In conclusion, cartoning is an essential process in the packaging of pharmaceutical, food, and household products. Whether it's ensuring the safety and integrity of medicine boxes, providing attractive food packaging, or creating functional and eye-catching packaging for household goods, cartoning plays a vital role in every industry. By using innovative cartoning machines like those offered by Grand, manufacturers can improve their packaging processes, reduce costs, and ensure the quality and safety of their products.

With advances in vertical cartoning, eco-friendly materials, and high-speed machines, the future of packaging looks bright. Grand’s cartoning machines stand out for their efficiency, precision, and versatility, helping companies stay ahead in a competitive market.

References

"Packaging Materials and Their Impact on Product Safety." Journal of Packaging Technology, 2023.

"Innovations in Cartoning for the Pharmaceutical Industry." Pharmaceutical Packaging Review, 2023.