The Essential Role of Cartoning in Pharmaceutical, Food, and Household Packaging

The Science and Applications of Dry Granulation Machines: A Deep Dive into Roll Compactor Machines

Infusion bag filling machines are inseparable from modern medical care

Introduction

In the world of healthcare, precision and sterility are paramount. The packaging and delivery of infusion bags—used to administer intravenous fluids—require a meticulous process that ensures patient safety and efficacy. Infusion bag filling machines play a crucial role in this process, streamlining production while maintaining the highest standards of quality and sterility.

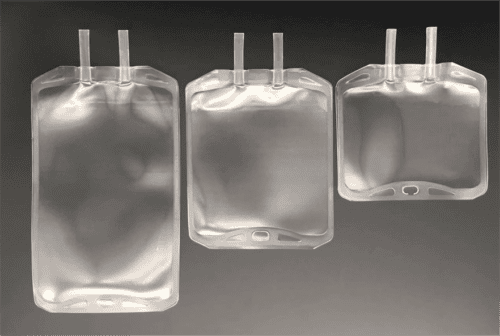

Non-PVC Infusion Bag

In this blog, we will explore the significance of bag infusion technology, its applications in medical devices, and how advancements in filling machines have revolutionized the packaging of sterile packaging solutions for medical fluids.

Understanding the Role of Infusion Bags in Healthcare

Infusion bags are essential medical devices used to administer intravenous (IV) fluids, medications, and nutrients directly into a patient's bloodstream. These bags are typically made from flexible, sterile materials and are designed to hold a variety of fluid formulations, from saline solutions to complex medications. Infusion bags are commonly used in hospitals, clinics, and ambulatory care settings to treat a wide range of conditions, from dehydration to chemotherapy.

A worker in cleanroom uniform is watching the Infusion soft bag filling and sealing machine.

The bag infusion process is highly sensitive. Any contamination or improper packaging could lead to significant health risks, including infection or incorrect dosage. Thus, maintaining a sterile and controlled environment during manufacturing is critical. This is where infusion bag filling machines come into play, ensuring that each bag is filled, sealed, and packaged under optimal conditions.

The Importance of Filling Machines in Infusion Bag Production

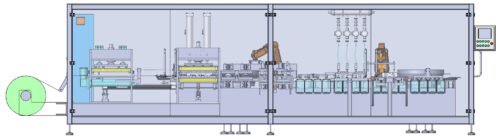

Filling machines are the backbone of the production process for infusion bags. These machines automate the filling process, ensuring precise and consistent amounts of fluid are added to each bag. Automation not only increases efficiency but also reduces the likelihood of human error, ensuring that every infusion bag meets the strict standards required for medical use.

Modern infusion bag filling machines are equipped with cutting-edge technology that enhances precision and flexibility. These machines can handle a wide range of fluid types, from simple saline solutions to more complex, multi-component medications. They also accommodate different bag sizes, from small bags for single-dose treatments to large volume bags used in critical care.

Infusion bag production line

By automating the process, filling machines improve production rates and consistency, helping manufacturers meet the growing demand for infusion bags. In addition, these machines ensure that the bags are filled to the correct level, eliminating the risk of overfilling or underfilling, both of which could impact patient safety.

Ensuring Sterility in Infusion Bag Manufacturing

One of the most critical aspects of bag infusion is ensuring the bags are sterile. Infusion bags are used in direct contact with patients’ circulatory systems, so any form of contamination could lead to severe infections or complications. Sterile packaging is a non-negotiable aspect of the manufacturing process, and filling machines designed for infusion bags are built to uphold the highest standards of cleanliness.

Manufacturers employ stringent protocols to maintain a sterile environment during the entire production process. This includes using cleanrooms, maintaining constant airflow, and using sterilized equipment. Infusion bag filling machines are often equipped with advanced sterilization systems that disinfect every part of the machine that comes into contact with the fluid or bag, ensuring that no contaminants are introduced during the filling process.

Moreover, many filling machines use automated sealing technologies to ensure that each infusion bag is securely closed and tamper-evident. This prevents any external contamination during storage or transport, keeping the bag sterile until it is used in medical procedures.

Innovation in Infusion Bag Filling Technology

Advances in technology have led to significant improvements in infusion bag filling machines. Traditional methods of filling and sealing were labor-intensive and prone to human error, but today’s automated machines are faster, more precise, and more reliable than ever.

Infusion bag filling station(Equipped with efficient peristaltic pump)

For example, Grand’s infusion bag filling machine is an industry leader, offering cutting-edge features such as:

High Precision Filling:

The machine ensures that every infusion bag receives the exact dosage of fluid, eliminating the risk of dosage discrepancies.

Enhanced Sterility Controls:

With state-of-the-art sterilization and aseptic filling technologies, these machines help maintain the sterility of the product throughout the entire production process.

Flexibility and Versatility:

Grand's machines can handle various fluid types, bag sizes, and even different packaging formats, making them suitable for a wide range of medical applications.

Advanced Monitoring and Control Systems:

These systems track every stage of production, from filling to sealing, ensuring that the infusion bags meet the highest standards of quality and safety.

Such innovations make Grand’s infusion bag filling machine a reliable choice for pharmaceutical manufacturers, enabling them to meet the growing demand for sterile medical devices and fluid delivery systems.

The Growing Demand for Infusion Bags and Medical Devices

The global demand for infusion bags is rising, driven by an aging population, increased prevalence of chronic diseases, and a growing emphasis on intravenous therapies. As healthcare providers continue to rely on infusion therapy to treat a wide range of conditions, the need for high-quality, sterile infusion bags has never been greater.

In addition to the traditional use of infusion bags for hydration and electrolyte balance, these devices are increasingly being used for the administration of antibiotics, chemotherapy, and other life-saving medications. As the healthcare industry continues to evolve, the demand for bag infusion systems that are safe, efficient, and reliable is expected to increase.

This trend has led to innovations in both infusion bag filling machines and the design of the bags themselves. New materials are being developed to improve bag strength and flexibility, while filling machines are becoming more sophisticated to accommodate the increasing complexity of medical treatments.

Key Considerations in Infusion Bag Filling

When designing an infusion bag filling machine, several factors must be considered to ensure that the machines can meet the unique needs of medical device manufacturing:

Precision and Accuracy: The filling machine must accurately fill each bag with the correct amount of fluid. Overfilling or underfilling can compromise the effectiveness of the treatment and harm patients.

Sterility: Ensuring that the infusion bags remain sterile throughout the filling and packaging process is paramount. The machine must include features that prevent contamination during production and packaging.

Flexibility: Given the variety of fluids, bag sizes, and treatment types, the filling machine must be adaptable to meet a wide range of requirements.

Efficiency: As demand for infusion bags increases, manufacturers need high-throughput machines that can fill and package large volumes of bags quickly while maintaining quality standards.

Regulatory Compliance: Infusion bag filling machines must meet strict regulatory standards, such as those set by the FDA and other health authorities, to ensure that the final product is safe and effective for use.

Conclusion

Infusion bags are critical components of modern healthcare, and the filling machines used to package them play an essential role in ensuring that these products are safe, sterile, and accurate. The growing demand for bag infusion systems highlights the need for innovation in both the manufacturing process and the equipment used.

Grand’s infusion bag filling machine stands out for its cutting-edge technology, ensuring that pharmaceutical manufacturers can produce high-quality sterile packaging solutions efficiently. With its precision, flexibility, and advanced monitoring systems, Grand’s machines provide the reliability needed to meet the increasing demand for infusion bags in the global healthcare market.

By investing in state-of-the-art infusion bag filling machines, manufacturers can not only improve production efficiency but also contribute to the global effort to provide safe and effective medical treatments to patients worldwide.

References

"The Role of Infusion Bags in Healthcare Delivery." Medical Devices Journal, 2023.