High Shear Mixer Pharma Granulator

Fluidized Bed Pharmaceutical Granulator

Dry Granulation Pharma Machine

Grand’s pharmaceutical machinery applies to capsules, tablets, pills, liquids, granules, powders, and ointments.

Specification

| Feeding Motor: | 0.4kw |

| Feeding Speed: | 0-30rpm |

| Whole Grain Motor: | 0.75kw |

| Hydraulic Motor: | 0.75kw |

| Max oil Pressure: | 10mpa |

| Host Size: | 900x760x1650mm |

| Weight: | 450kg |

Features

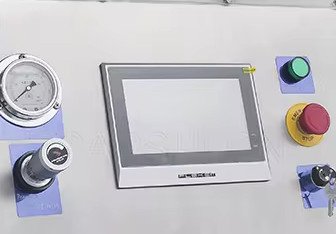

Automated Control System: The PLC-controlled human-machine interface ensures that operations are synchronized with the program, simplifying the overall process through automation.

Variable Speed Control: Both the stirring blade and cutter feature variable frequency speed control, allowing you to adjust the speed to suit different granulation requirements.

Integrated Mixing and Granulation: The entire process of dry and wet mixing granulation occurs within the same closed container, reducing adhesive usage by 25% and shortening drying time compared to traditional methods.

Machine Details

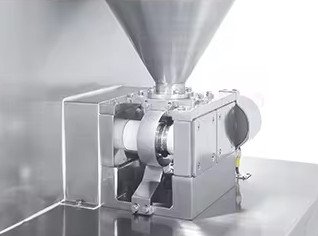

Compaction Unit

Composed of two compacting rollers which run in opposite directions to press powder.

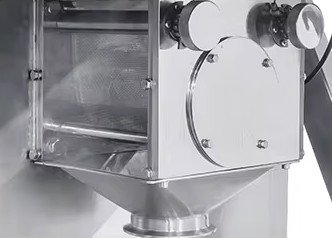

Feeding

Consists of a feeding motor, a gear reducer, a hopper, and a taper feeding auger

Granulation Part

Consists of a granulation motor,a stepless speed reducer

PLC&HMI Control System

Chosen From well-known brands

FAQS

Here are some FAQs

1How does the Dry Granulation Pharma Machine work?

The machine compacts dry powder into hard sheets using two rollers, then granulates them into particles, all managed by a PLC system.

2Can the machine handle both dry and wet materials?

No, this machine is specifically designed for dry granulation and is not suitable for wet materials.

3What kind of industries can use this machine?

The machine is ideal for pharmaceutical, food, and chemical industries that require granulation of dry materials.

4Is the machine easy to operate?

Yes, the PLC-controlled interface simplifies operation, making it user-friendly and efficient.

5Can the speed be adjusted during granulation?

Yes, both the stirring blade and cutter speeds can be adjusted to meet the specific needs of different granulation processes.

6WWhat are the main components of the machine?

The machine comprises a compaction unit, a feeding system, a granulation unit, and a PLC & HMI control system.

7Does the machine meet GMP standards?

Yes, the machine is built to comply with GMP standards, ensuring high-quality production.

8What are the space requirements for installation?

The machine has a compact size of 900x760x1650mm, making it suitable for various production environments with limited space.