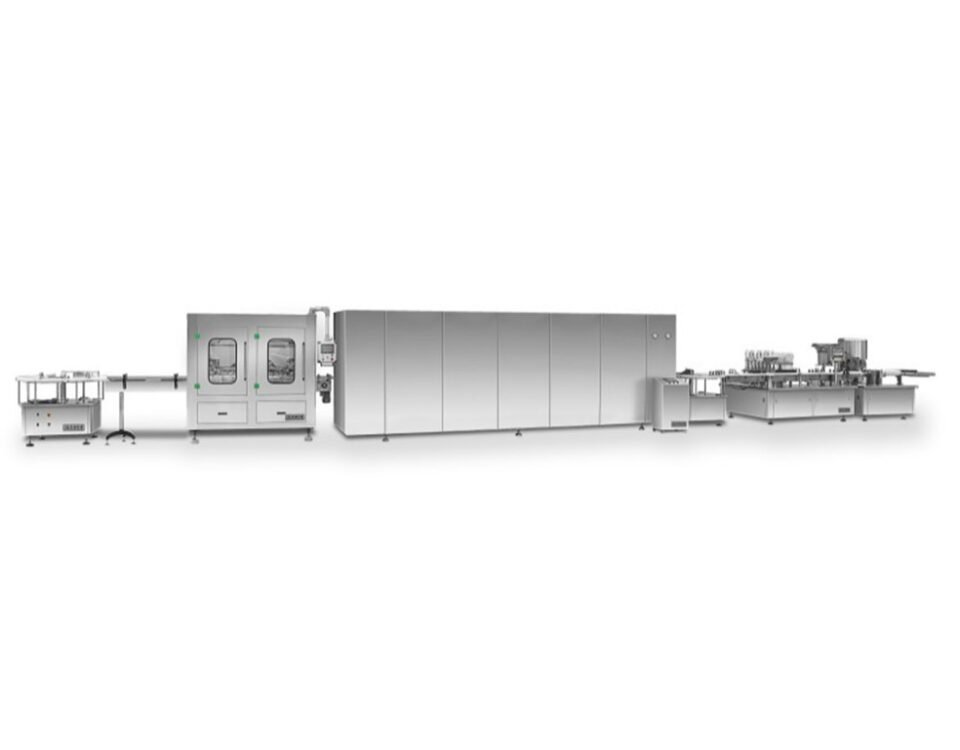

Vial and Ampoules Packaging Line

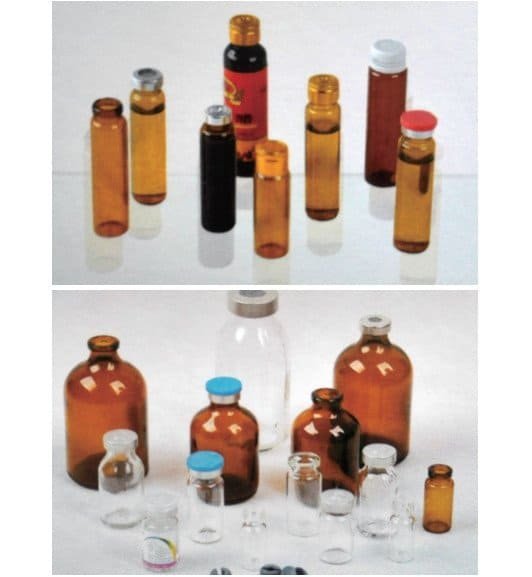

Our fully automated, GMP-compliant production lines are tailored for antibiotic vials, vials and sterile powders. Designed for high-quality pharmaceutical processing, this integrated system seamlessly combines washing, drying, filling, and capping operations to ensure optimal efficiency and product safety.

Features

Tailored Solutions: We offer customized vial packaging solutions designed to match your specific capacity requirements and vial sizes, helping you optimize costs.

On-Site Support: Our technicians will travel to your location to assist with the installation of the packaging line and provide comprehensive training for your staff.

Long-Term Assistance: 10-year commitment to technical support services

How Our Vial and Ampoules Packaging Line Works?

Process flow:

Bottle Washing & Pre-Cleaning → Drying & Sterilization → Precise Filling → Capping & Sealing → Quality Inspection & Packaging

Specifications

| Max Output: | 200-300 Cartons/Min |

| Max Fomming area and deptn: | 480x160x25mm |

| Leaflet Size: | (100-200)x(100-150)mm |

| Carton size: | (70-200)x(25-100)x(14-80)mm |

| Carton Material: | 250-350g/m2 |

| Air Compressor: | 0.6-0.8Mpa≥0.8m/min |

| Leaflet material: | 50-70g/m |

| Power: | 22Kw |

| Weight: | 4000kg |

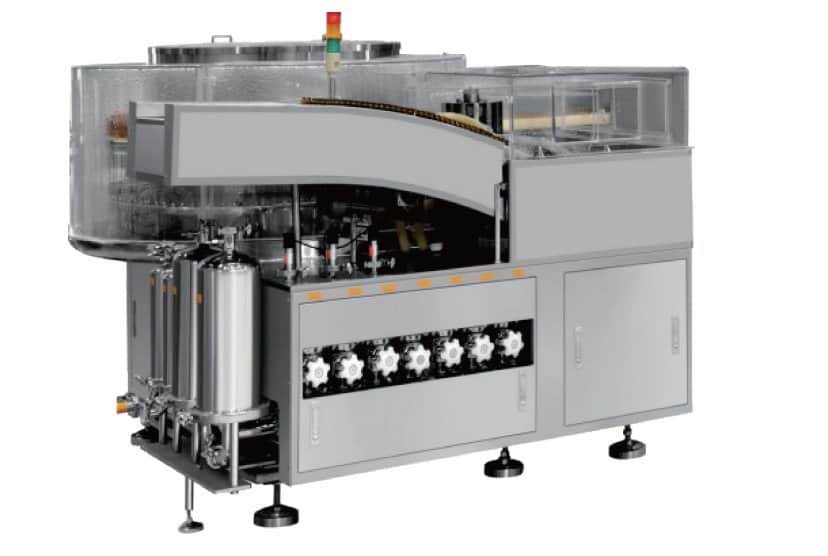

Ultrasonic vial cleaning machine

Ultrasonic Pre-Wash: Bottles are initially subjected to an ultrasonic cleaning cycle. The machine uses ultrasonic waves to dislodge contaminants from both the interior and exterior surfaces.

Sterilization dryer

Uniform Drying: Bottles move through a hot air tunnel where even heat distribution rapidly dries them, preventing moisture retention.

Simultaneous Sterilization: The same process effectively sterilizes bottles by eliminating microbial contaminants, with optional cooling (air or water) for controlled temperature reduction.

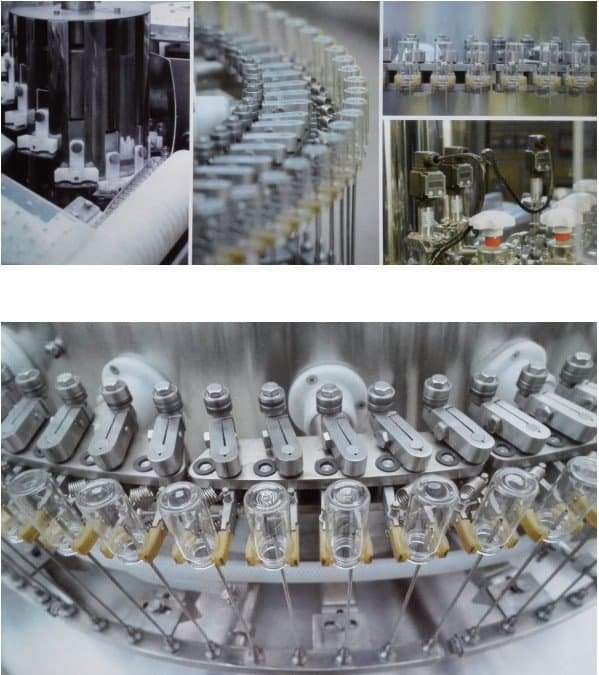

Machine Details

Feeder

Filling Device

FAQS

Here are some FAQs

Contact Us