Granulator Pharmaceutical

Granulators for the pharmaceutical industry

We provide high-speed shear granulators (wet and dry) and Fluidized bed Granulator for pharmaceutical manufacturer.

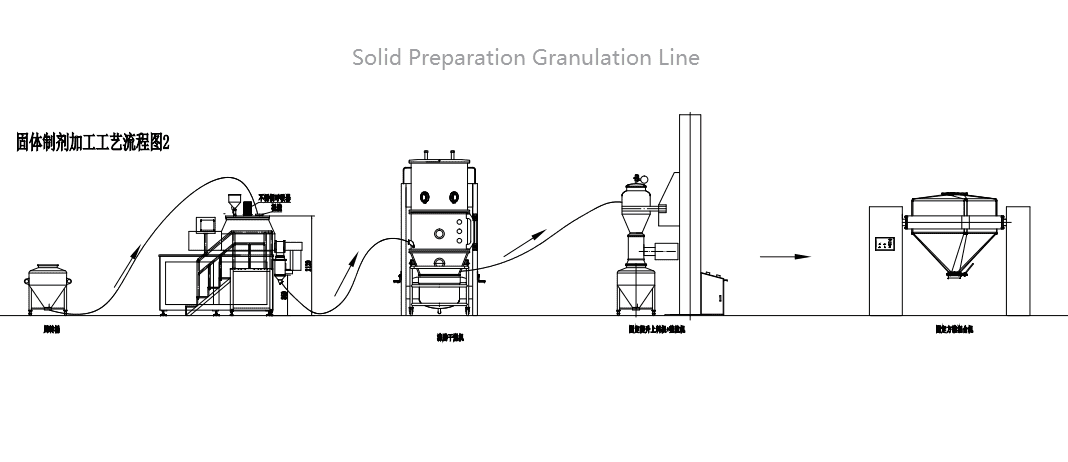

Granulator Pharmaceutical Connection|Production Line

Granulator Pharmaceutical Line Transmission| The production line can be combined with the selection of granulators according to the customer's pharmaceutical production process, including wet mixing granulator, dry granulator, dry whole machine, etc., suitable for laboratories, pharmaceutical factories combined production lines.

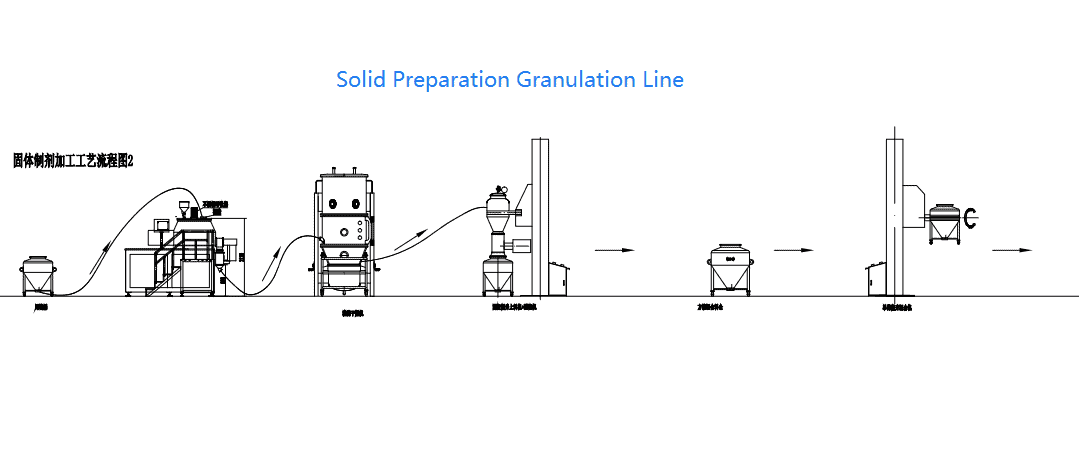

How Our Solid Preparation Granulation Line Works?

Process flow chart :

Powder Feeding & Wet Granulation → Fluidized Drying → Blending → Tablet Compression → Coating (Optional) → Packaging

Granulator Pharmaceutical Features:

Supply Types: Rapid mixing pharma granulator, fluid bed granulator, High Speed mixing granulator.

Application: Powder,liquid, granules mixing granulation.

Service Target: Pharmaceutical, biomanufacturing company, and agricultural products companies.

Granulation Process: Wet and Dry Granulation.

Why Choose Us

Strong Supply Chain

We have a powerful granulator supply chain, fast response manufacturing, and quick delivery.

Dry&Wet Mixing

We provide dry and wet mixing granulation, with full functionality to meet all granulation needs.

Competitive Price

All of our pharmaceutical granulators are shipped from the factory, helping you save the intermediate costs.

High Quality Promise

We always put quality first, because only high quality can stand in the world.

Video Gallery

The design of the granulator also optimizes the ratio of materials in the product container, leading to energy savings and improved overall efficiency.

Temperature within ±20℃ during heating or cooling, ensuring optimal granulation conditions.

Granulator Pharmaceutical ABC

Here are some FAQs

This process improves the flow and compression characteristics of the powders, making them suitable for tablet formation or capsule filling.

Each type offers unique advantages, such as enhanced mixing efficiency or suitability for specific materials.

For example, high-shear granulators are ideal for wet granulation, while fluidized bed granulators excel in uniform granule production.

Lubrication of moving parts and timely replacement of worn components are also necessary for optimal performance.

offering precise control over granulation parameters to achieve consistent results for sensitive biological materials.

ensuring uniform granulation for various applications.

Related Articles

Contact Us