Rapid Mixing Pharma Granulator

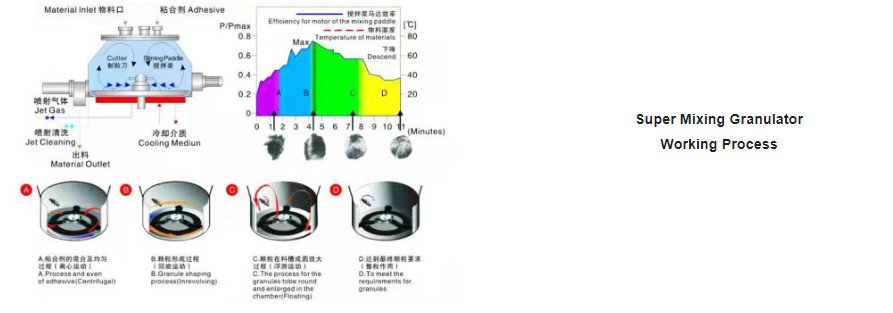

The Fast Mixing Granulator, developed by the Grand Group, is an advanced granulation machine that seamlessly integrates mixing, wet granulation, and precise control. Powered by Siemens PLC microcomputer control and an intuitive touch screen, it offers easy operation with high automation, managing temperature, running time, and speed with precision.

Equipped with V-shaped cutters that can shift sideways and adjust height, the machine shortens granulation time while ensuring consistent results. Its unique stirring paddle effectively scrapes attachments from the container's walls and bottom, reducing buildup and minimizing material crashing, thereby enhancing granulation efficiency. The granulator employs sandwich pot technology to finely cut powder to less than 8%.

The microcomputer-controlled system allows for precise temperature adjustments, maintaining the tank's temperature within ±20℃, whether heating or cooling the material, to ensure optimal granulation conditions.

Features

Versatile Adhesive Addition: Equipped with a dripping device, allowing adhesives to be added either by dripping or mixing. This feature is designed to meet the needs of various medicines, saving approximately 20% on adhesive usage while ensuring high-quality granulation.

Comprehensive Safety Protections: The machine includes a reliable safety protection system. Access to the main machine requires a password, ensuring that the machine remains secure when the lid is open. The lid features a vacuum feeding port with a dust removal device and an adhesive feeding port. Additionally, a viewing window allows operators to monitor particle formation at different stages, ensuring a dust-free operation.

Advanced Sealing Technology: The stirring paddle is sealed with a rubber pad, employing a double composite technology that combines oil and air screws to overcome the common issues associated with shaft seal failures. The pull-out type shaft seal is detachable, making it easy to maintain.

Enhanced Efficiency: The granulator completes the mixing and granulation process in a single step, improving efficiency by 4-5 times. The resulting particles are solid and have a high granulation rate.

Customizable Output: The machine allows for the tailoring of particle size and bulk density to specific requirements, making it especially useful for mixing medicinal powders and extracts.

Specifications

| Warranty: | 5 Year |

| After-sales Service: | Whole Life After-Sale Service |

| Capacity: | 75-210kg |

| Working Volume: | 150-420L |

| Max Inner Diameter: | 1150mm |

| Speed of Stirring Motor: | 20-200rpm |

| Stirring Motor Power: | 30kw |

| Speed of Cutting Motor: | 50-3000rpm |

| Cutting Motor Power: | 11kw |

| Machine Dimensions (L*W*H): | 3300mmX2300mmX2550mm |

| Machine Weight: | 3000KG |

| Specification: | 3300x2300x2900mm |

Machine Details

Cylinder For Output

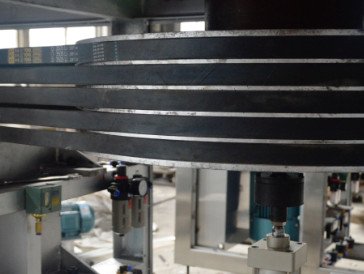

Mixing Blade

Mixing pot

Output