Твердость таблетки: почему это важно в фармацевтическом производстве

8 лучших производителей V-миксеров в 2025 году

Упаковка в блистерную упаковку: обзор, виды, преимущества и как выбрать правильное решение

Введение

«Глобальные исследования рынка фармацевтической упаковки показывают, что блистерная упаковка продолжит свой устойчивый рост и, по прогнозам,... лишь немного уступит по доле рынка упаковке в бутылки».аутсорсинг Этот отраслевой анализ подчеркивает, как блистерная упаковка становится популярным выбором для защиты и распространения продукции, почти соперничая по популярности с традиционной упаковкой в виде бутылок. От аптек до отделов игрушек блистерная упаковка есть везде, предлагая удобный способ запечатывания предметов между формованной пластиковой оболочкой и подложкой. В этом подробном руководстве мы рассмотрим, что такое блистерная упаковка, ее распространенные применения, различные типы (проталкиваемая, отклеивающаяся, раскладушка, скользящая, защищенная от детей), ключевые факторы при выборе правильного решения для блистерной упаковки, а также преимущества и ограничения этого стиля упаковки. Мы также объясним, почему компании предпочитают Грандпак зарекомендовали себя как надежные поставщики оборудования для всех видов блистерной упаковки.

Обзор блистерной упаковки и ее применения

Упаковка блистерной упаковки относится к типу предварительно сформированной пластиковой упаковки, которая обычно включает в себя прозрачную полость или карман, отформованный под продукт, с подложкой из картона, пластиковой пленки или алюминиевой фольги, которая запечатывает его. Проще говоря, блистерная упаковка похожа на прозрачную пузырь в котором хранится и демонстрируется продукт, часто прикрепленный к картонной карточке или с фольгированной крышкой.

Этот формат упаковки широко используется для небольших потребительских товаров, продуктов питания и особенно фармацевтических препаратов. Зайдите в любую аптеку или супермаркет, и вы увидите примеры повсюду: таблетки лекарств, запечатанные в блистеры с одной дозой, батарейки или лампочки, зажатые между пластиком и картоном, фигурки и электроника в жестких «ракушках-ракушках» и даже жевательная резинка или мятные леденцы в выталкиваемых фольгированных упаковках.

Блистерные упаковки популярны, поскольку они позволяют покупателям видеть продукт (важно для маркетинга), защищают товары от влажности и загрязнения и часто обеспечивают защиту от несанкционированного вскрытия (это очевидно, если блистер был открыт) для безопасности. Многие фармацевтические таблетки упаковываются в блистерные упаковки, чтобы гарантировать, что каждая доза изолирована и сохранена до использования, что может улучшить приверженность пациентов и сократить ошибки дозировки по сравнению с бутылками. В целом, упаковка в блистерные упаковки предлагает универсальный и удобный способ упаковки всего: от таблеток и витаминов до игрушек, инструментов и косметики.

Сравнение различных типов блистерной упаковки

Не все блистерные упаковки одинаковы. Существует несколько типов блистерной упаковки, каждый из которых разработан с различным способом открытия или структурой, чтобы соответствовать различным продуктам и потребностям потребителей. Ниже мы сравниваем некоторые из наиболее распространенных типов:

Блистерная упаковка Push-Through

Прозрачная блистерная упаковка с фольгированной подложкой. Проталкивание Блистерная упаковка — классический стиль большинства упаковок лекарств. В этой конструкции продукт (например, таблетка или капсула) находится внутри полости с подложка из фольги. Пользователь просто проталкивает продукт через фольгу с пластиковой стороны — алюминиевая фольга тонкая и разрывается под давлением, позволяя таблетке выскочить. Этот тип блистерной упаковки чрезвычайно распространен в фармацевтической промышленности для лекарств и таблеток в разовой дозе.

Он обеспечивает как защиту, так и некоторую защиту от детей (поскольку каждая таблетка запечатана отдельно), при этом взрослым ее относительно легко открыть, надавив. Проталкиваемые блистеры также используются для некоторых пищевых продуктов, таких как жевательная резинка или мятные леденцы, где вы выдавливаете конфету через фольгированную оболочку.

Главное преимущество — удобство: каждая доза или часть доступна сама по себе, а неиспользованные порции остаются запечатанными и защищенными до тех пор, пока они не понадобятся. Подложка из фольги также обеспечивает эффективный барьер для влаги и кислорода, помогая продлить срок годности чувствительных продуктов. Следует отметить, что проталкиваемые упаковки зависят от силы пользователя; если фольга сделана очень прочной (для более высокой защиты), может потребоваться больше усилий, чтобы протолкнуть ее, что приводит к следующему типу — отслаивающимся блистерам.

Отрывные блистерные упаковки

Упаковка в виде отрывного блистера похожа по внешнему виду на проталкиваемые упаковки, но способ открытия отличается. Вместо того, чтобы проталкивать продукт через крышку, пользователь снимает защитную пленку или фольгу чтобы достать предмет. Эти блистеры обычно имеют язычок или уголок, который можно поднять, чтобы снять пломбу целиком.

Отрывные блистеры часто используются, когда для защиты продукта требуется более прочная или многослойная фольга (например, чтобы создать упаковку, которую дети не смогут легко проткнуть). Требуя отрывного действия, которое часто требует некоторой ловкости, производители могут сделать упаковку более сложной для открывания детьми, но при этом доступной для взрослых. Вы найдете отрывные блистеры в некоторых лекарствах (особенно на рынках или в продуктах, где правила требуют дополнительной безопасности), а также в некоторых медицинских приборах или стерильных продуктах.

Например, медицинские блистерные лотки для таких устройств, как шприцы или хирургические инструменты, часто используют отрывную бумагу или подложку Tyvek® — медицинский работник отрывает крышку, чтобы сохранить стерильность. Преимущество отрывных упаковок заключается в том, что они могут включать сильная печать (даже толстая фольга или пластиковый ламинат), который обеспечивает отличную защиту от влаги или взлома, но взрослый может намеренно снять пломбу, когда это необходимо. Недостатком является то, что они добавляют дополнительный шаг — вместо быстрого «хлопка» проталкивания, вы должны найти край и отклеить, что может быть сложным для некоторых, если конструкция не очень хорошая.

Блистерные упаковки-раскладушки

Блистерные упаковки-раскладушки — это те самые жесткие, навесной пластик Упаковки, которые вы часто видите в упаковках для электроники, игрушек или оборудования на полках магазинов. У блистера-ракушки есть верхняя и нижняя пластиковая оболочка, которая закрывается как ракушка (часто один кусок пластика, сложенный сам на себя, или два куска, слитые вместе).

В отличие от фармацевтических блистеров push-through, раскладушки обычно не имеют фольгированной подложки; вместо этого весь продукт заключен в жесткий пластик, иногда с картонной вставкой внутри для маркировки. Раскладушки отлично подходят для предотвращения краж и защиты продуктов — они прочные, их нельзя открыть без явных повреждений, и их можно повесить на крючки для демонстрации. Однако они печально известны тем, что трудно открыть для потребителей. Пластиковые края часто запаяны или заварены, поэтому для разрезания требуются ножницы или нож (и осторожность, так как пластик может быть острым).

На самом деле, разочарование из-за труднооткрываемой упаковки-раскладушки настолько распространено, что его называют «обернуть ярость», и это больше, чем просто досада — по оценкам, тысячи людей ежегодно попадают в отделение неотложной помощи из-за травм, полученных при попытке открыть складные упаковки. Несмотря на сложность открытия, складная блистерная упаковка широко используется для таких товаров, как наушники, USB-кабели, картриджи и многие розничные товары среднего размера, поскольку она обеспечивает отличную видимость товара и надежную защиту от повреждений или несанкционированного доступа. Некоторые складные упаковки имеют удобные функции, такие как перфорированные линии или встроенные язычки, которые немного облегчают открытие, но пользовательский опыт все равно может быть грубым. Ключевым моментом является то, что складные упаковки ставят безопасность и отображение выше легкого доступа.

Блистерная упаковка слайдов

Упаковки со слайдами в блистере — это умная вариация, разработанная для легкой сборки и иногда повторного использования. В упаковке со слайдами в блистере прозрачный пластиковый блистер имеет фланцевые края, которые оберните вокруг трех сторон вставной карточки, оставляя одну сторону открытой. Продукт помещается в блистер, а затем в открытую сторону блистера вставляется картонная карточка, которая «защелкивается» во фланцах и удерживает продукт внутри.

По сути, карта служит подложкой, но не запечатана навсегда — она удерживается на месте структурой блистера. Это означает, что не требуется термосварки или клея, что может быть удобно для упаковки небольшого объема или ситуаций, когда вы можете захотеть повторно открыть упаковку, не повредив ее. Слайд-блистеры часто можно увидеть в розничной торговле для таких товаров, как маленькие игрушки, принадлежности для рукоделия, электронные аксессуары или рыболовные снасти, где возможность упаковывать на лету или позволять клиентам вытаскивать демонстрацию продукта полезна. Они также позволяют создавать привлекательные двухсторонние дизайны карт, поскольку карту можно снять и напечатать на обеих сторонах.

Компромисс в том, что пакеты слайдов не как защищенный от кражи или детей как запечатанные блистеры — если карта не закреплена (иногда для ее фиксации используется кусок ленты или пластиковая кнопка), человек потенциально может вытащить карту в магазине. Но для многих продуктов этот стиль обеспечивает хороший баланс защиты и доступности. Это гибкий тип упаковки блистера, который компании выбирают, когда хотят избежать инвестиций в оборудование для запечатывания или когда они ценят упаковку, которую можно открыть без инструментов.

Блистерная упаковка с защитой от детей

Упаковка блистера, защищенная от детей, предназначена для того, чтобы оградить любопытных детей от опасных продуктов (таких как рецептурные препараты или химикаты), при этом позволяя взрослым потребителям достаточно легко получить доступ к продукту. Существует несколько подходов к созданию блистеров, защищенных от детей.

Одним из распространенных методов является использование специальная многослойная фольгированная подложка который требует комбинации действий для открытия. Например, пакет может потребовать от пользователя отслаивать верхний слой а затем нажмите таблетку пропускают через второй слой — это двухэтапный процесс, который маленькому ребенку очень сложно понять и выполнить.

Другой подход заключается в интеграции блистера во внешнюю коробку или рукав с запирающим механизмом. Вы могли видеть упаковки таблеток, где вам нужно совместить стрелки на внешнем рукаве с определенным блистером или вытащить блистерную карту из картонного конверта, защищенного от детей. В любом случае, цель состоит в том, чтобы соответствовать нормативным стандартам, которые требуют, чтобы упаковка была «значительно сложной» для детей младше пяти лет, чтобы ее можно было открыть в течение разумного времени, но не слишком сложной для взрослых. Блистерные упаковки, защищенные от детей, часто используют более прочные материалы (более толстая фольга или пластик) и могут не иметь функций легкого открывания, таких как угловые язычки, специально для того, чтобы помешать попыткам детей. Например, опиоидный препарат может поставляться в блистерной упаковке с системой открывания-выталкивания, где каждая доза запечатана отдельно, а язычок открывания намеренно маленький или сложный.

Пожилые люди или люди с ограниченной ловкостью иногда могут испытывать трудности с этим, поэтому производителям приходится искать баланс между безопасностью и доступностью, иногда предоставляя такие опции, как специальные инструменты для открытия или альтернативную упаковку по запросу фармацевта. Подводя итог, можно сказать, что блистерная упаковка с защитой от детей — это прежде всего безопасность: она использует формат блистера для индивидуальной защиты доз и добавляет уровни сложности (отклеивающиеся язычки, запирающиеся рукава, более прочные уплотнения), которые действуют как сдерживающий фактор для детей.

Заключение и рекомендации: выбор правильного партнера (Grandpack)

Выбор подходящей блистерной упаковки для вашего продукта имеет решающее значение, но также важен выбор правильного оборудования и опыта для создания этих упаковок. Вот где вступает в дело партнерство с надежным поставщиком упаковочного оборудования.

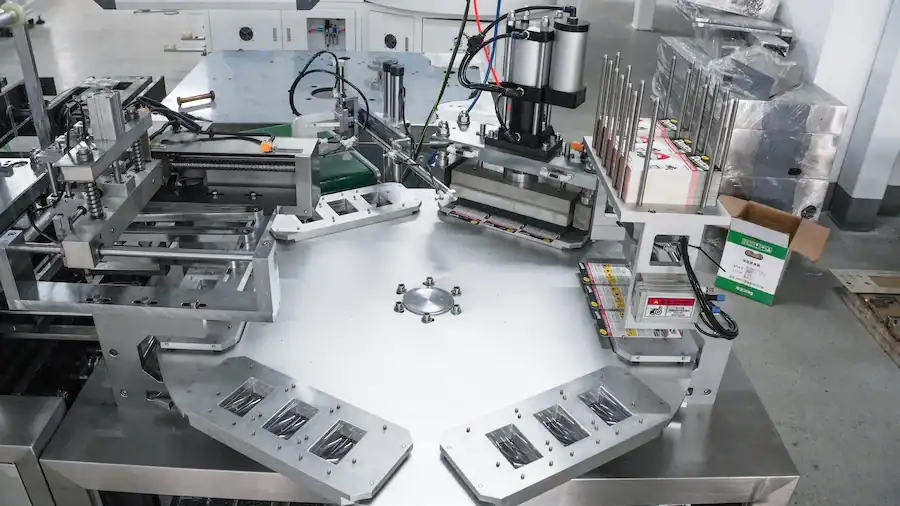

Грандпак является одним из таких поставщиков, известных в отрасли своим качеством и надежностью. Grandpack является ведущим производителем фармацевтического упаковочного оборудования (базируется в Гуанчжоу, Китай), специализирующимся на передовых блистерные упаковочные машины и другие автоматизированные решения, подчеркивающие эффективность и безопасность.

Имея более чем десятилетний опыт работы в сфере упаковки, Grandpack заслужила репутацию превосходной компании — компания соответствует стандартам GMP и сертифицирована по стандарту ISO 9001:2015, а также обслужила более 3000 клиентов в более чем 100 странах. Такой послужной список говорит об их надежности и опыте.

Работая с Grandpack, вы получаете доступ к передовым технологиям и поддержке для ваших потребностей в блистерной упаковке. Независимо от того, нужен ли вам компактный полуавтоматический блистерный запайщик для коротких тиражей или высокоскоростная полностью автоматическая линия блистерной упаковки, Grandpack, скорее всего, найдет решение в своей линейке продуктов. Их оборудование разработано для точности и универсальности, способно обрабатывать различные типы блистерной упаковки — от формирования пластиковых блистеров и запечатывания фольгированных крышек для таблеток до блистерных карточных машин для потребительских товаров. Компании, которые внедрили машины Grandpack, часто отмечают улучшение пропускной способности и постоянства (например, снижение затрат на рабочую силу за счет автоматизации запечатывания блистерных упаковок или минимизацию ошибок за счет таких функций, как визуальный осмотр и точное дозирование).

Помимо оборудования, Grandpack предоставляет руководство по настройке правильной упаковочной установки для вашего конкретного продукта. Это включает в себя настройку инструментов (форм для блистеров) и оптимизацию параметров процесса, чтобы гарантировать, что ваши блистерные упаковки будут идеальными — с прочными швами, четкими оттисками и соответствием нормативным стандартам. Выбирая проверенного партнера, такого как Grandpack, вы фактически получаете Консультант по упаковке и поставщик в одном лицеОни могут помочь вам сориентироваться в факторах, которые мы обсудили (материалы, соответствие продукта, автоматизация), и внедрить решение по блистерной упаковке, которое обеспечит максимальную защиту вашего продукта и эффективность ваших операций.

Подводя итог, можно сказать, что упаковка в блистерную упаковку — это мощный вариант упаковки, который при правильном подходе приносит пользу как производителям, так и потребителям. Она обеспечивает видимость, защиту и удобство, особенно для продуктов в единичных дозах и розничных товаров. С правильной упаковкой и правильным партнером вы можете быть уверены, что ваши продукты не только хорошо защищены и привлекательны на полке, но и эффективно и безопасно доставлены вашим клиентам — упакованные в блистерную упаковку, которая действительно соответствует вашим потребностям.