Tablet Presi Bakımı: Hap Presi Yağlama Kılavuzu

Blister Ambalaj Neden İlaç Sektörünün En Önemli Kalesidir?

2025'in En İyi Blister Ambalaj Makinesi Önerileri

İlaç, tıbbi cihaz ve yüksek değerli elektronik ürünlerin rekabet ortamında, üretim verimliliği ve ürün bütünlüğü son derece önemlidir. Güncel olmayan paketleme süreçleri, darboğazlara, artan atıklara ve ürün güvenliğinin tehlikeye girmesine yol açarak kârınızı doğrudan etkileyebilir. Çözüm, daha hızlı, daha akıllı ve daha güvenilir bir teknolojiyi benimsemekte yatmaktadır. Üretim hattınızı yükseltmek istiyorsanız, mükemmel çözümü aramanız... blister paketleme makinesi Burada sona eriyor. Kapsamlı bir incelemenin ardından, 2025 için en iyi seçimimizi açıklıyoruz: Grand DPH260TK Yüksek Hızlı Rulo Plakalı Blister Paketleme MakinesiBu, yalnızca kademeli bir yükseltme değil; paketleme teknolojisinde devrim niteliğinde bir sıçrama. Bu makale, bunun tam olarak nedenini açıklayacak.

DPH260TK'nin İlaç Ambalajında Altın Standart Olmasının Nedeni

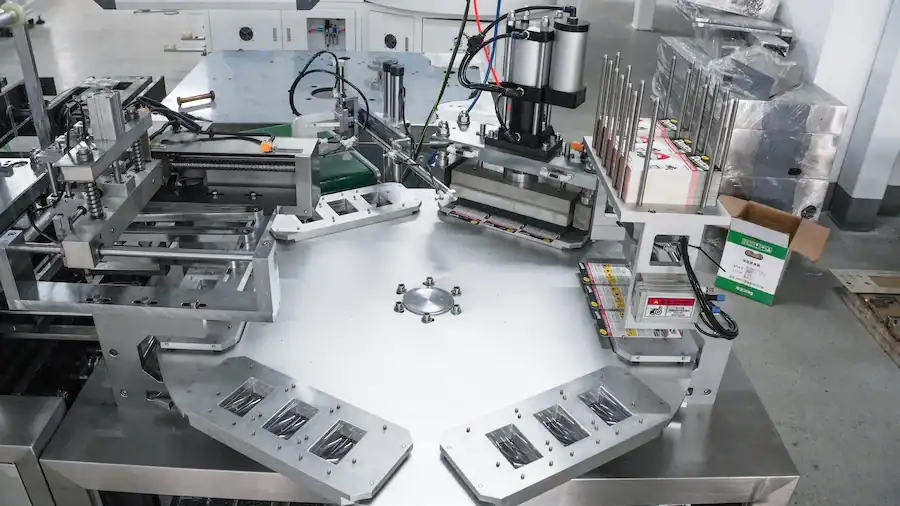

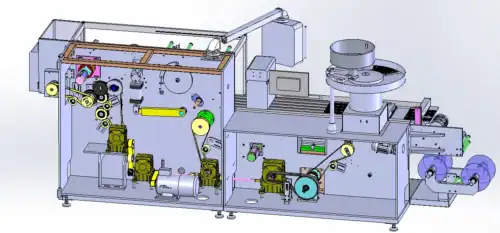

Grand DPH260TK, hem düz plakalı hem de silindir tipi makinelerin avantajlarını ustalıkla bir araya getirerek öne çıkıyor. Sonuç, sektör için yeni bir standart belirleyen bir hız, hassasiyet ve çok yönlülük merkezi. Modern üretimin temel zorluklarını çözmek ve operasyonel kapasitenizi dönüştürebilecek bir hızda kusursuz, güvenli bir şekilde kapatılmış blister ambalajlar sunmak üzere tasarlandı.

Grand PharmaPro DPH260TK: 2025 yılında eşsiz hız ve güvenilirlik için tasarlandı.

Eşsiz Hız ve Verimlilik: Yüksek Hacimli Üretimin Özü

DPH260TK'nin en dikkat çekici özelliği inanılmaz hızıdır. Dakikada 180'e kadar delme kapasitesiyle, geleneksel blister makinelerinden 4 ila 5 kat daha hızlı çalışır. Bu sadece ham hızdan ibaret değil; aynı zamanda akıllı bir tasarımdan da kaynaklanıyor. Ünlü Alman Uhlmann ikinci nesil tasarımına dayanan makinenin şanzıman sistemi, her kritik istasyon için ayrı redüktör motorları kullanır. Bu sayede, hantal zincir ve dişlilerin yerini daha temiz ve daha doğrudan tahrikli bir sistem alır.

Faydaları iki yönlüdür:

- Gelişmiş Stabilite: Yüksek hızlarda, senkron kayış tahriki titreşimleri ve çalışma gürültüsünü en aza indirerek, duruşa neden olan mekanik stres olmadan tutarlı bir performans sağlar.

- Daha Fazla Kontrol: İşlemin her aşaması (şekillendirme, yapıştırma, delme) bağımsız olarak kontrol edilir, bu sayede daha ince ayarlar ve üstün senkronizasyon sağlanırken, daha az enerji tüketilir.

Ölçeklendirmeyi düşünen herhangi bir tesis için bu ilaç blister ambalajlama makinesi Kaliteyi feda etmeden agresif üretim hedeflerini karşılamak için gerekli verimi sunar.

Baştan Sona Hassasiyet: Kusursuz Blister Ambalajların Sağlanması

Hassasiyet olmadan hız anlamsızdır. DPH260TK, malzeme beslemesinden son şekillendirmeye kadar iş akışının her aşamasına hassasiyeti entegre ederek öne çıkar.

Süreç, gelişmiş bir PVC/PTP besleme sistemiyle başlar. Otomatik, fotoelektrik kontrollü bir açma mekanizması, ister dolu ister neredeyse boş bir rulo kullanın, pürüzsüz ve tutarlı bir gerilim sağlayarak, daha düşük kapasiteli makinelerde görülen besleme sorunlarını önler. Benzersiz bir arıza koruma sensörü, bir malzeme kırılması veya sıkışması tespit edildiğinde makineyi anında durdurarak değerli malzemeden ve zamandan tasarruf sağlar.

Malzeme beslendikten sonra servo tahrikli çekiş sistemiyle buluşur. Standart darbe tabanlı servoların aksine, DPH260TK dahili bobin konumlandırmalı bir servo motor kullanır. Bu sayede harici elektromanyetik parazitlere karşı dayanıklıdır ve yalnızca 6 mikron (6 mikron) gibi inanılmaz bir konumlandırma hassasiyeti sunar. PVC daha sonra yavaşça ısıtılır Teflon-kaplamalı plakalar, herhangi bir "sıcak nokta" olmadan pürüzsüz ve tutarlı blister oluşumu için mükemmel derecede homojen bir ısı dağılımı sağlar. Şekillendirme kalıpları elektronik olarak parlatılır ve her blisterin tek tip bir duvar kalınlığına sahip olmasını garanti ederek her seferinde mükemmel, profesyonel kalitede bir ambalaj oluşturur. Bu ayrıntı seviyesi, onu üstün kılan şeydir. blister makinesi paketleme çözüm.

Üstün Blister Ambalaj Sızdırmazlık Makinesi

Bir blister ambalaj, ancak üzerindeki conta kadar iyidir. Conta, ürünü nemden, oksijenden ve kirleticilerden koruyarak etkinliğini ve raf ömrünü garanti eder. İşte DPH260TK, kendisini gerçekten de birinci sınıf bir ürün olarak öne çıkaran nokta burasıdır. blister ambalaj kapatma makinesi.

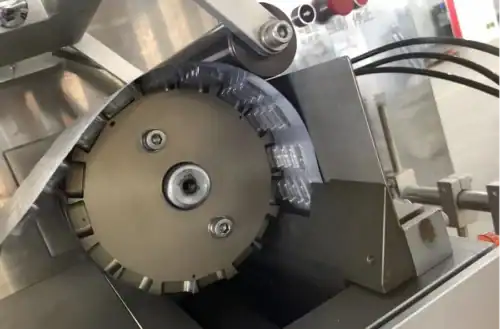

Yenilikçi silindir pres sistemi her pakette mükemmel ve güvenilir bir sızdırmazlık sağlar.

Yenilikçi Hava Yastığı ve Silindir Pres Sızdırmazlığı

Makine, mükemmel bir çift yöntem yaklaşımı kullanıyor. İlk olarak, bir hava yastığı mekanizması çalışma sırasında bir tampon görevi görerek aşırı basıncı emer ve makinenin uzun ömürlü olmasına katkıda bulunur. Sızdırmazlık işlemi ise bir rulo pres sistemiyle gerçekleştirilir.

İşte nasıl çalışır: Blister ağı ve alüminyum folyo, tek ve ince bir çizgi halinde temas eden iki silindir arasından geçer. Bu küçük temas alanı, basıncı yoğunlaştırarak daha kısa bekleme süresiyle sağlam ve kapsamlı bir ısıl sızdırmazlık sağlar. Isıya maruz kalma süresi kısa olduğundan, ürün veya ambalaj malzemelerine termal hasar riski olmadan genel makine hızı önemli ölçüde artar. Ayrıca, makine durduğunda, ısıl sızdırmazlık silindiri otomatik olarak kalkar ve ısı radyasyonunun blisterleri deforme etmesini önler; bu tasarım, yaygın bir sorun olan ve bu sorunu zarif bir şekilde çözer.

Kesintisiz Çalışma için Gelişmiş Soğutma

Sürekli çalışma için ısı yönetimi kritik öneme sahiptir. DPH260TK, çok yönlü bir soğutma sistemine sahiptir. Isıl sızdırmazlık silindiri hava soğutmalıdır; bu tasarım, eski su soğutma sistemlerindeki olası sızıntıları ve bakım masraflarını akıllıca önler.

Aynı zamanda, silindir kalıbın kendisi de bir su soğutma devresi kullanır. Bu, uzun üretim süreçleri boyunca kalıbın optimum sıcaklıkta kalması için çok önemlidir. Isının birikmesini ve blister şeklini etkilemesini veya alüminyum folyonun kırışmasını önleyerek, günün son paketinin ilkiyle aynı kalitede olmasını sağlar.

Akıllı, Güvenli ve Kullanıcı Dostu: Sadece Bir Makineden Daha Fazlası

DPH260TK, yalnızca performans için değil, aynı zamanda onu kullananlar için de tasarlanmıştır. Akıllı özellikleri, kullanımı kolaylaştırır, güvenliği artırır ve en yüksek endüstri standartlarına uyumu garanti eder.

Akıllı Kontrol ve Otomasyon

Merkezinde makine blisteri sezgisel bir İnsan-Makine Arayüzü (HMI) ve güçlü bir PLC sistemidir. Operatörler parametreleri kolayca ayarlayabilir, dahili yardım kılavuzuyla sorunları giderebilir ve birden fazla ürün için ayarları kaydedebilir. Bu, hızlı geçişlere olanak tanır; veritabanından kayıtlı parametreleri çağırır ve farklı bir ürün spesifikasyonunu çalıştırmaya hazır hale gelirsiniz.

Kalite kontrolü entegre bir sistemle daha da otomatikleştirilir Kamera İnceleme SistemiEndüstriyel kontrol ekranına sahip bu sistem, programlaması ve ayarlaması kolaydır. Eksik veya kırık tabletleri titizlikle kontrol ederek, hattan çıkan her paketin kusursuz olmasını sağlar. Arızalı paketler, delme istasyonuyla mükemmel bir 1:1 senkronizasyonla çalışan 90 derecelik ileri geri hareket eden emiş plakası reddetme sistemi tarafından otomatik olarak çıkarılır.

Güvenlik ve GMP Uyumluluğu için Üretildi

İlaç endüstrisinde güvenlik ve uyumluluk vazgeçilmezdir. DPH260TK, "GMP" (İyi Üretim Uygulamaları) gerekliliklerini karşılayacak şekilde baştan sona tasarlanmıştır. Ürünle temas eden tüm parçalar yüksek kaliteli paslanmaz çelik ve diğer toksik olmayan malzemelerden üretilmiştir.

Makine çok sayıda güvenlik özelliğiyle donatılmıştır, bunlar arasında şunlar yer alır:

- Otomatik Kapanma: PVC veya alüminyum folyo bittiğinde veya herhangi bir ısıtma elemanı sıcaklık sınırını aştığında makine duracak ve operatörü uyaracaktır.

- Acil Durdurma: Operatörlerin ayarlama ve kalıp değişimleri sırasında korunmasını sağlamak için emniyet cihazları belirgin bir şekilde yerleştirilmiştir.

Modern İhtiyaçlar İçin Çok Yönlülük: Tabletlerden Özel Şekillere

Bazı makineler tek bir işleve sahipken, DPH260TK çok yönlülük için tasarlanmıştır. Sağlam tasarımı, standart tabletler ve kapsüller için idealdir (isteğe bağlı otomatik kapsül besleyici ile). Yine de hassasiyeti, onu genellikle diğer sistemleri zorlayan düzensiz şekilli ürünler için de mükemmel bir şekilde uygun hale getirir. Bu uyarlanabilirlik, onu sıradan bir makineden çok daha fazlası yapar. masa üstü blister paketleme makinesi; kapsamlı bir endüstriyel çözümdür.

Sistem hem Alu/PVC hem de Alu/Alu ambalajları işleyebilir ve sağlam yapısı, özel ambalajlarda bulunan dayanıklılığı anımsatır. Alloyd blister ambalaj makinesi sistemler. Kolayca yırtılabilen çizgiler oluşturmak için delme istasyonu gibi isteğe bağlı özellikler (ideal) blister kart yapıştırma makinesi (uygulama) ve son derece yapılandırılabilir sıcak damgalı toplu kodlama sistemi, makineyi tam ihtiyaçlarınıza göre uyarlamanıza olanak tanır.

Karar: 2025'in En İyi Blister Ambalaj Makinesi

İşletmeler için blister ambalaj makinesi ilaç endüstrisi Grand PharmaPro DPH260TK, modern ambalajlama teknolojisinin zirvesini temsil ediyor. Günümüz pazarının kritik ihtiyaçlarını karşılıyor: daha yüksek hız, ödünsüz kalite, operasyonel esneklik ve akıllı, kullanıcı dostu kontrol talebi. Atıkları en aza indirir, çalışma süresini en üst düzeye çıkarır ve hem güvenli hem de profesyonel bir nihai ürün üretir.

2025 ve gelecek yıllarda üretim hedeflerinizi karşılayacak ve hatta aşacak bir makineye yatırım yapmayı düşünüyorsanız, DPH260TK tartışmasız en iyi tavsiyemizdir.

Üretim hattınızı devrim niteliğinde değiştirmeye hazır mısınız? Bugün uzmanlarımızla iletişime geçin Grand DPH260TK blister ambalaj makinesinin işletmenize nasıl fayda sağlayabileceği hakkında daha fazla bilgi edinmek için.