Grand Screening Machines

Lớn offers a full line of industrial screening machines engineered for precision, throughput, and reliable uptime. Our portfolio includes the Circular Swing (round swing) screening machine, Three-Dimensional Vibrating Screen (rotary vibration / XF series), Dust-free Feeding Station, Horizontal Airflow Screener, Square Swing Screen, and Ultrasonic Screening Machines. These screening machines serve powder, granule, slurry and sticky materials across food, pharmaceutical, chemical, metallurgical, and industrial processes.

Each model is designed around the same principle: control the motion and amplitude of the screen surface so material follows a long, repeatable trajectory on a compact screen area — improving separation accuracy and maximizing screen utilization. Whether you need a high-capacity industrial vibrating screen for coarse classification or an ultrasonic screening machine to handle micro powders and electrostatic fines, Grand has an optimized solution.

Product overview-screening machine Series

Phát triển doanh nghiệp của bạn với Grand

How to request a quote — submission form (sample)

Please fill out the form below and a Grand representative will respond within one business day.

Company name

Contact name & title

Email | Phone

Product of interest (dropdown): XF three-dimensional vibrating screen / YBS circular swing / Ultrasonic screening / Horizontal airflow / Square swing / Dustless feeding station

Target material (brief description)

Required capacity (kg/hr or t/hr)

Desired mesh size or target separation cut

Special requirements (cGMP, 316L, ATEX, PLC integration)

Attachment: Material spec sheet (optional)

Preferred delivery country / installation site

Key product families

Circular Swing Screening Machine (YBS series)

Low-frequency swing action that mimics manual rocking to produce a 3D rolling motion. Ideal for fragile, irregular, or clog-prone materials that require precise separation on a relatively small screen area.Three-Dimensional Vibrating Screen (XF series / rotary vibration)

Uses an upright motor with eccentric weights top and bottom to generate controlled horizontal–vertical–incline motion. Best for high-precision, probability and fine screening (2–500 mesh).Dust-free Feeding Station

Sealed, negative-pressure feed stations to transfer material into screeners without dust escape, enabling safe integration into production lines and GMP environments.Horizontal Airflow Screener

For ultrafine powders, dry suspensions, and applications where a controlled air path enhances screening of light or low-density particles.Square Swing Screen

Similar swing/rocking motion in a square geometry — preferred when layout, stacking, or modular integration demands a square footprint.

Typical applications

- Pharmaceutical powders and granules (active pharmaceutical ingredients, excipients) — pharmaceutical screening machine

- Food powders, starches, seasonings

- Chemical pigments, catalysts, and additives

- Metal powders and powders for additive manufacturing

- Slurries, suspensions and wastewater solids

- Plastics, resins, and polymer beads

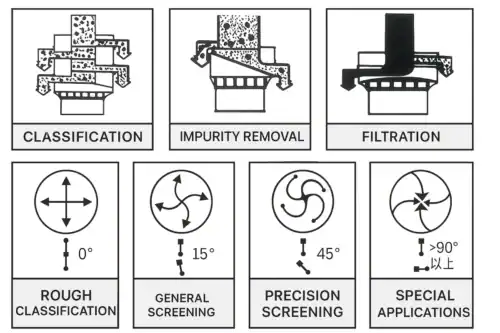

What makes these machines different (screening machine principle & function)

Grand screening machines control:

Motion trajectory — three-dimensional or swing motion creates a long path on a compact surface so particles separate more thoroughly.

Amplitude & inclination — adjustable eccentric weights or inclinable plates let you tune horizontal versus vertical movement to optimize throughput and capture rates.

Anti-block measures — rubber bouncing balls, brush rollers, or ultrasonic mesh excitation that prevent blinding and maintain consistent efficiency.

Modularity — quick-open clamp rings, interchangeable mesh frames, and optional automatic mesh lifters reduce downtime for maintenance and changeover.

Core features & benefits

- Lên đến 5× throughput compared to conventional vibration screens for certain materials (per Grand field data).

- Screening accuracy 90–95% with proper configuration.

- Multiple cleaning options: rubber balls, rotating brush, or Swiss-import ultrasonic cleaning for sticky or electrostatically charged powders.

- Sealed / dust-free design for safe integration into production lines and compliance with GMP.

- Quiet operation: noise levels designed below 80 dB.

- Robust construction: food-grade 304 / 316L stainless options; full-304 mirror finish or powder-coated Q235 frames as required.

- Quick mesh change: fast-open clamping ring — no bolts to unscrew.

- Low dynamic foundation load and balanced mechanical design for long life and reduced vibration transmission to building structures.

- 24/7 global support with rapid response service.

Why choose Grand screening machines/Vibrating screen?

Engineering depth & field validation:

Designs are based on decades of separation experience and on-site validation across pharma, food, chemical and metals plants.

Flexible configurations:

From standard stainless finishes to 316L and GMP-ready builds with dust-free feeding stations.

Maintenance-friendly design:

Quick-open clamp rings and modular mesh frames reduce downtime. Optional automatic mesh lifters make mesh changes fast and safe.

Advanced anti-blocking solutions:

Swiss-import ultrasonic cleaning and multiple mechanical cleaning methods reduce maintenance frequency and increase uptime.

Technical parameters (representative)

| Người mẫu | Screening Diameter (mm) | Screening Area (m²) | Mesh Range | Layers | Motor Power (kW) |

|---|---|---|---|---|---|

| XF-400 | φ340–φ360 | 0.09–0.10 | 2–500 mesh | 1–3 / 1–5 | 0.18 |

| XF-600 | φ540–φ560 | 0.22–0.25 | 2–500 mesh | 1–3 / 1–5 | 0.25 |

| XF-800 | φ720–φ760 | 0.40–0.45 | 2–500 mesh | 1–3 / 1–5 | 0.55 |

| XF-1000 | φ910–φ950 | 0.65–0.71 | 2–500 mesh | 1–3 / 1–5 | 0.75 |

| XF-1200 | φ1100–φ1150 | 0.95–1.05 | 2–500 mesh | 1–3 / 1–5 | 1.1 |

| XF-1500 | φ1400–φ1450 | 1.5–1.6 | 2–500 mesh | 1–3 / 1–5 | 1.5 |

| Người mẫu | Diameter (mm) | Screening Area (m²) | Space Requirement (m³) | Layers | Power (kW) |

|---|---|---|---|---|---|

| YBS600 | 600 | 0.29 | 0.4 | Up to 5 | 0.25 |

| YBS1000 | 1000 | 0.71 | 1.2 | Up to 5 | 1.5 |

| YBS1200 | 1200 | 1.11 | 1.6 | Up to 5 | 2.2 |

| YBS1600 | 1600 | 1.83 | 2.5 | Up to 5 | 2.2 / 4 |

| YBS2000 | 2000 | 2.62 | 3.6 | Up to 5 | 2.2 / 4 |

FAQs (screening machine)

Q1: What screen mesh sizes do you support?

A1: Grand screening machines support a wide mesh range from coarse (2 mesh) to very fine (up to 500 mesh).

For ultrafine separations we recommend ultrasonic screening plus optimized feed and anti-blinding accessories.

Q2: How do you clean or prevent mesh clogging?

A2: Options include bouncing rubber balls, rotating brush rollers, and ultrasonic mesh vibrators.

For sticky or electrostatic powders, the ultrasonic option is especially effective.

Q3: Can you supply GMP / food-grade finishes?

A3: Yes. We offer 304 and 316L stainless steel contact surfaces with mirror polishing (down to 0.4 µm where required),

sealed dust-free feed hoppers, and traceable materials for regulated industries.

Q4: What is the lead time and installation support?

A4: Lead time varies by model and configuration (typically 4–12 weeks).

We offer commissioning, on-site installation support, and remote startup assistance.

Spare parts and service contracts are available.

Q5: How do I choose between the XF three-dimensional screen and the YBS swing screen?

A5: XF three-dimensional screens excel at fine, probability-based separations and are highly tunable via eccentric weights.

YBS circular swing screens are ideal for materials prone to clogging or requiring gentle handling (fragile or irregular particles).

We can recommend a model after you submit material and capacity details.