Automatic Alu Blister Packing Machine DPP-180L

Pharma Packaging line

Alu Blister Packing Machine DPP-80 Button

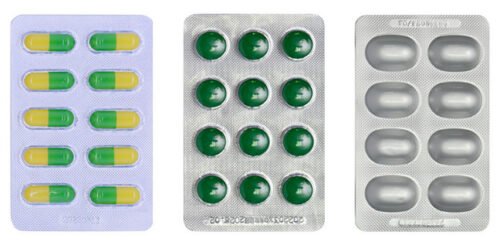

DPP-80 with Button designed for blister packaging of capsules, tablets, injections, pills, bolus, candies through Alum or medical PVC, widely applied in pharmaceutical, food, electronic, and medical device industries.

Features

High-Power Transmission: Utilizes an original high-power transmission mechanism with a chain-driven system to eliminate gear transmission noise and imply a highly efficient working process.

Customizable Electrical Control Components: The electrical control system can be configured with options for material leakage detection, defect detection, and elimination using an Omron sensor, based on customer requirements.

4-Position Combination: Integrates PVC molding, feeding, heat sealing, punching, and packing into a seamless process.

Photoelectric Control: Equipped with a photoelectric control system that ensures synchronized and stable multi-station operations, along with automatic PVC and PTP feeding.

Advanced Detection and Correction: Features a photoelectric detection and correction device, along with servo motor traction and a printing device for enhanced accuracy.

Wide Application: Suitable for packaging capsules, plain tablets, sugar-coated tablets, injections, special-shaped products, medical equipment, and light food items.

Specifications

| Overall Dimension: | 1996*592*1229(mm) |

| Weight: | 350kg |

| Noise index: | <75dBA |

| Punch frequency: | 10-38tims/min |

| Production capacity: | 1980plates/hour |

| Max. forming area and depth: | 70*105*12(mm) |

| Standard stroke range: | 35-75mm |

| Standard plate size: | 80x57mm |

| Air Pressure: | 0.4-0.6Mpa |

| Total Power: | 220V 50Hz 3Kw |

| Main Electrode Power: | 0.75Kw |

| PVC Hard Film: | 0.15-0.5*120(mm) |

| PTP aluminum film: | 0.02-0.035*120(mm) |

| Dialysis Paper: | 50-100g*120(mm) |

| Mould cooling: | Tap water or recycling water |

Machine Details

Alu Alu tablet packaging

Orbital tablet aluminum plastic packaging

Tablets, capsules aluminum plastic packaging