7 Maintenance Tips for Tube Filling Machine

What’s the Difference Between Hard Gelatin Capsules and Soft Gelatin Capsules?

Top 10 vial filling machine manufacturers In The World(2024)

What is a Vial Filling Machine?

Vial filling machine accurately fills liquid or powder products, such as pharmaceutical drugs, vaccines, or biologics, into vials. It is an important piece of equipment for the pharmaceutical, medical, and biotech industries.

These machines operate in cleanroom environments to ensure precise, contamination-free filling. They often combine functions like filling, capping, and labeling, making them ideal for automated production lines.

What International Standards Should Vial Filling Machines Comply With?

Vial filling machines must comply with major international standards to ensure equipment safety, efficiency and product quality:

- GMP (Good Manufacturing Practice)

Design and operation must adhere to good manufacturing practices to ensure product sterility and safety.

- FDA (US Food and Drug Administration)

Machines exported to the US must meet FDA regulations, especially for pharmaceutical use.

- ISO 14644 (Cleanroom Standards)

Ensures equipment can operate in clean environments, critical for aseptic production.

- CE Certification

Required for equipment sold in the EU market to meet safety, health, environmental and consumer protection requirements.

Technologies Behind Vial Filling Machines

Vial filling machines utilize various modern technologies to improve accuracy, efficiency and safety:

- Robotic Automation: Automatic robotic arms enable high-speed, precision filling, capping, labeling and other operations while reducing human intervention.

- Isolator Technology: Aseptic isolation systems prevent contamination during filling to ensure product sterility.

- Online Weighing: Real-time monitoring of fill volumes per container ensures accurate dosing and consistency.

- IoT Integration: Enables remote monitoring and maintenance. Factories can track performance, predict maintenance needs and improve efficiency.

As demand rises for vaccines, biologics and pharmaceuticals, the vial filling machine market sees steady growth. These machines play a vital role for major companies in the pharma and biotech space, with North America, Europe and Asia holding the largest markets.

Why Are Vial Filling Machines Important for Factories and Production Lines?

For pharmaceutical and biotechnology factories, utilizing vial filling machines is essential. It not only increases the automation and sterility of the production line, but also meets strict industry regulations.

In addition, it can greatly improve production efficiency, reducing manual operation risks and costs while maintaining quality standards. This enables large-scale output with ensured product quality and safety.

As such, vial filling machines are indispensable equipment for modern pharmaceutical and biologics factories seeking to optimize manufacturing throughput while guaranteeing standards.

Top 10 vial filling machine manufacturers:

Now you have a clear idea of what Vial Filling Machines are all about. With that in mind, let’s learn more about the leading Vial Filling Machine Manufacturers out there.

1. Romaco

Type:Development, production, and packaging solutions for pharmaceuticals, health products, food, cosmetics and chemicals

Location (Headquarters):Karlsruhe Germany

Founded: 1997

Certification:cGMP

Brief introduction:

Romaco is a leading international supplier of machinery and integrated system solutions for developing, producing, and packaging pharmaceutical, nutraceutical, food, cosmetic, and chemical products - all from a single source.

The company says, "Developing a new drug is a complex, expensive, and time-consuming endeavor, often taking 10-15 years, with a high probability of failure. However, its potential to improve human health and alleviate suffering makes the effort worthwhile.

The journey of a new drug from a promising lab compound to pharmacy shelves filled with vials depends on the scalability of powder filling. During development, researchers meticulously fill batches of capsules or vials for clinical trials. However, transitioning to large-scale production requires a dramatic increase in output while maintaining precise dosing and powder integrity. This necessitates shifting from manual or semi-automated processes to rugged, high-speed equipment that can consistently and efficiently fill large numbers of capsules or containers with the life-saving powder.

2. Grand

Type:Pharmaceutical Machinery, Pharmaceutical Packaging Machinery

Location (Headquarters):Guangzhou China

Founded: 2006

Certification:CE, SGS, ISO

Brief introduction:

Since 2006, Grand has been one of the earliest pharmaceutical machinery manufacturers in China. The company's mission of "earning limited profits to gain high quality trust" serves as Grand's business goal.

With 18 years of manufacturing experience, they have won the trust of customers in more than 120 countries.

They are committed to becoming number one in China's pharmaceutical machinery industry, representing quality "Made in China" products to the world and shedding the reputation of cheap and low quality goods!

Grand focuses on R&D, sustainable development, environmental protection, energy saving, and improving production efficiency.

3. Syntegon

Type:Processing and packaging solutions for pharmaceuticals and foods

Headquarters: Crailsheim, Germany

Location (Headquarters):Crailsheim Germany

Founded: 1969

Certification: GMP

Brief introduction:

Syntegon is a strategic partner for processing and packaging solutions for the pharmaceutical and food industries, providing seamless processes, innovative technologies and sustainable solutions.

In the pharmaceutical industry, Syntegon's line solutions enable the safe, high-quality production, processing, filling, inspection and packaging of liquid and solid pharmaceutical products. In the food industry, their flexible and reliable systems are used for the production and packaging of confectionery as well as dry and frozen foods.

With 160 years of experience, 39 locations in 17 countries and 1,200 service experts, Syntegon provides customers with a seamless platform for their production operations. Their 1,400 R&D employees work on leading technologies every day - 2,100 patents and patent applications confirm the company's innovative strengths.

4. Cozzoli

Type:Liquid filling machines, powder filling machines and ampoule filling machines

Location (Headquarters): Somerset, New Jersey

Founded: 1919

Certification: ISO 9001:2015

Brief introduction:

For over a century, Cozzoli Machinery Company has been manufacturing precision filling machinery for the packaging and bottling industries.

As a global leader in the design, manufacturing, and servicing of automatic cleaning, sterilization, filling, and sealing systems, Cozzoli is your preferred supplier for all packaging and filling applications.

Their wide range of liquid filling machines, powder filling machines, and ampoule filling machines are custom designed and manufactured to customers' high-quality standards and specifications.

5. Watson Marlow

Type: Peristaltic pumps and filling equipment

Location (Headquarters): Falmouth, Cornwall, UK

Founded: 1956

Certification: cGMP

Brief introduction:

Since 1956, Watson Marlow has been creating the world's most innovative fluid management solutions. Thousands of companies use their technology to manage industrial processes and manufacture products that impact people's lives every day.

They have helped thousands of process and maintenance engineers on every continent solve fluid management challenges. The company offers proven technology and a global network of professional industrial engineers.

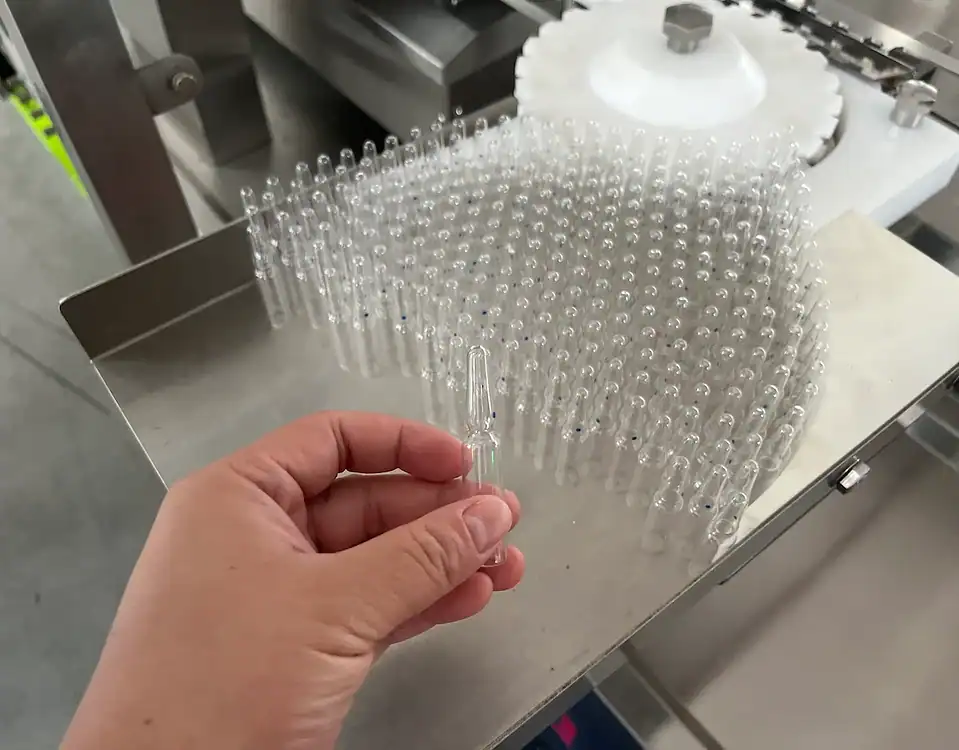

6. Triumph Junheng Co.,Ltd

Type: Borosilicate glass packaging

Location (Headquarters):Hebei Province, China

Founded: 2016

Certification: ISO

Brief introduction:

China National Building Materials Group is a world leader in six areas: cement, concrete, gypsum board, fiberglass, wind turbine blades, and waste heat power generation.

It focuses on R&D, manufacturing, and distribution, and is the largest building materials group in China. For six consecutive years, it has been a Fortune Global 500 company.

Kaisheng Technology, a high-tech enterprise under the group, specializes in special glass fibers, fiberglass, and non-metallic minerals. Its core is the Bengbu Glass Industry Design Institute.

7. Bosch Packaging Technology

Sources: Bosch

Type:Filling, sealing, cartoning and flow wrapping machines

Location (Headquarters): Bangalore, India

Founded: 1922

Certification: ISO

Brief introduction:

Bosch Packaging Technology is a leading global provider of packaging solutions. Its Indian branch has become a trusted brand in the industry. Bosch Packaging Technology offers a comprehensive range of products, including form-fill-seal machines, cartons, and flow wrappers. These solutions provide efficient and reliable packaging for a variety of needs.

8. Tetra Pak India

Type: Food processing and packaging solutions

Location (Headquarters): Pune, Maharashtra, India

Founded: 1987

Certifications: ISO 14001, ISO 27001, ISO 45001

Brief introduction:

Since its inception, the company has been committed to developing cutting-edge technologies and solutions that help keep food safe and accessible everywhere. Now, more than ever, they are working to protect food, people and the planet.

They do this by developing food processing and packaging solutions that meet the needs of customers around the world, while remaining committed to sustainability. Their dedicated team of innovators and collaborators uses the latest science and technology to work tirelessly to find answers to some of the biggest challenges facing the global food and beverage industry today.

9. PACK'R

Type: Liquid filling and capping equipment

Location (Headquarters): Milwaukee, Wisconsin, USA

Founded: 1989

Certifications: ISO 9001

Brief introduction:

Founded in France in 1989 by Pierre Guillon, PACK'R designs and manufactures liquid filling equipment for diverse industries. Since the beginning, PACK'R has been busy refining and improving its equipment by developing Monobloc filling machines and the Clean & Play cleaning system. The company established PACK'R North America in Atlanta, GA in 2008.

Today, PACK'R enjoys a reputation as an expert in liquid filling equipment. Its custom design and manufacturing capabilities are second to none. PACK'R is committed to providing the highest-quality filling machines, supported by a team of highly skilled technicians. It is well-known worldwide for developing advanced technologies for complex products.

10. Higee Machinery Co., Ltd.

Type: Filling, packaging and labeling equipment

Headquarters: Shanghai, China

Founded: 2005

Certifications: CE Certification

Brief introduction:

HIGEE MACHINERY specializes in the design and production of filling, capping, and labeling machine lines for various industries, especially the water, beverage, food, pharmaceutical, cosmetic, and chemical sectors.

The company's machines have been exported to over 100 countries worldwide. They have the advantage of formulating customized solutions to meet each customer's specific requirements, with a focus on delivering premium quality and service to establish and maintain long-standing business relationships with customers across the world.

Conclusion

Vial filling machines play an integral role in sterile filling of vials across pharmaceutical and biotech. Meeting stringent standards, utilizing the latest tech for automation and isolation, they enable precise large-scale production.

As demand increases for critical vaccines, medicines and biologics, major manufacturers like Romaco and Syntegon drive market growth globally. Their innovations in filling equipment are indispensable for modern factories to optimize manufacturing quality and output.