Overview of China’s Tablet Press Market

Features and applications of liquid capsule and soft capsule filling machines

Liquid Capsule Filling Machine: Introduce,Working Steps,DIY and Application

Liquid filled capsules allow to deliver drugs in liquid or semi-solid form. They usually come with a gelatin shell, which can effectively retain the porous drug. Liquid filled capsules are quite popular among drugs because of accurate dosing capabilities. Moreover, anyone can easily swallow them when compared to syrups or suspensions. On top of that, liquid filled capsules can protect the drug compound from degradation as well.

To make such liquid filled capsules, you will need to use a liquid capsule filling machine. They support the production of liquid filled capsules in large quantities. As you manufacture the capsules, you can ensure minimal oxygen exposure and faster sealing processes. This can maintain overall stability of the capsules. There are advanced monitoring systems, which can help the capsules to meet highest quality standards as well. Let’s explore more on what liquid capsule filling machines are all about.

What is a Liquid Capsule Filling Machine?

A liquid capsule filling machine has an automated system. It can produce sealed, liquid filled gelatin or vegetarian capsules. Such a machine offers a higher level of precision and efficiency. You can use it to fill empty two-piece capsule shells with a liquid medication. Then you can seal the halves together. This will create an enclosed delivery system.

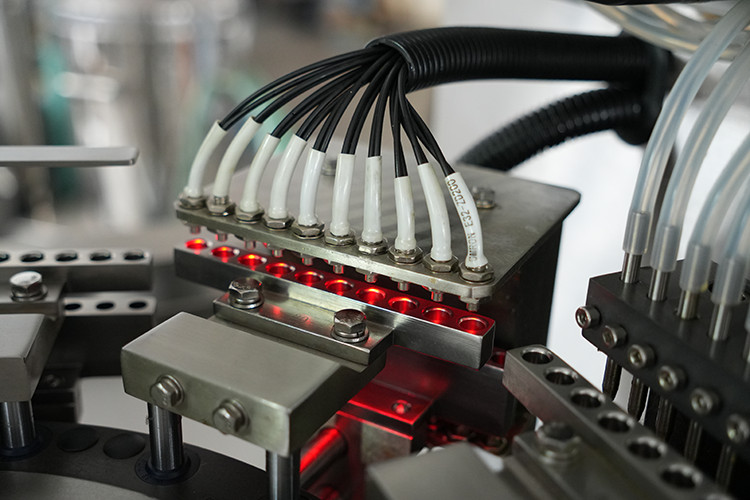

Image Source: https://grandpackmachine.com/portfolio-item/liquid-capsule-filling-machine-nyf-600/

Inside a liquid capsule filling machine, you can find numerous modules. They will orient, open, fill, seal, and eject finished capsules. You can expect to get an output rate of around 15,000 to 35,000 capsules per hour. Most modern liquid capsule filling machines offer fully automatic or semi-automatic filling. They have mechanical parts coordinated by a microprocessor.

Key components and functions include:

- Capsule Feeder: Orients empty capsules and feeds them into filling area.

- Capsule Opener: Carefully pulls apart the two halves of the capsule shell.

- Liquid Dosing Station: Accurately dispenses precise liquid volumes into lower capsule half

- Sealing Station: Joins and seals the filled capsule halves to avoid leakage.

- Exit and Collection: Ejects and counts sealed liquid capsules.

It is possible to use a liquid capsule filling machine to fill many different types of oils as well. They include fish oil, evening primrose oil, or even flaxseed oil. They enable high quality and efficient production of liquid capsules. You can also expect them to help with quality assurance.

How Does a Liquid Capsule Filling Machine Work?

Liquid capsule filling is an automated process to produce sealed liquid-filled capsules. It works through the following main steps:

1. Capsule Orientation

Capsule orientation is the first key step in liquid capsule production. In here, empty capsules will load into a vibrating feeder tray. It contains holes to fit the capsules and process them. The feeder trays come with a custom design. They have a vibrating action to capture the bulk supply of empty capsules. You can also ensure that the capsules align upright at the time of filling them.

2. Capsule Opening

Within the capsule opening module, properly oriented capsules will enter mechanical splitter. These wedges can precisely hold the lower half of the capsule in a stationary position. Then a vacuum suction cup manifold will descend to grab the upper capsule in position.

Pneumatic cylinders will then provide an upward pulling motion against the immobile lower half. It will gently separate the two halves without causing any damage. The automated process will eventually pull apart the two vegetarian or gelatin capsule shell pieces. It will provide support to fill up the upcoming liquid.

3. Liquid Filling

Near the liquid filling station, pre-measured and verified doses will get injected to the capsules. They will get into the lower half of the capsule. This advanced pump system will ensure that the liquid volumes remain consistent.

Then there are nozzle tips that will direct the liquid in coated microchannels. It will avoid any contact with metal components during the filling process. There are special valves that can prevent unwanted dripping between dosing. Overall solutions ensure highly accurate filling quantities into opened capsule half-shells.

4. Capsule Joining

At the capsule joining module, the separated capsule halves will connect. The upper half shells will return to the lower liquid-filled halves. There is an automated mechanical pick and place arm available to support this.

In some machines, infrared heat is available to slightly melt the gelatin capsule edges before joining. This enables optimal sealing adhesion to prevent any medication leakage. The output is securely sealed liquid capsule units fully enclosing the inner liquid contents.

5. Exit & Inspection

Finally at the exit module, production batches of sealed liquid capsules exit the automated machine. It happens via a chute or collection bin. Rejected capsules will move into separate bins. The machine interface displays real-time counts for total production quantity and defect rates. Additional automated sensors can further inspect, count and pack finished liquid capsules.

How to Fill a Capsule with Liquid?

Automated liquid capsule fillers use advanced mechanical processes. As a result, they can continuously fill, seal, and discharge liquid-filled capsules. The integrated modular machines follow precise steps:

Bulk Feed

A large vibrating bin loads thousands of empty capsules. They align upright single file via the vibration energy.

Orientation

Feeder plates arrange and orient each capsule to sit perfectly upright. Improperly oriented capsules are rejected by optical sensors.

Separation

A wedge grip holds the lower capsule half stationary. Vacuum suction cups then separate the top and bottom halves.

Filling

Precision pump nozzles dispense exact amounts of oils, emulsions or liquid medications into the lower capsule halves.

Joining

Robotic arms join separated capsule halves, pressing the liquid-filled lower and upper halves back together.

Sealing

Infrared heat melts and fuses the capsule edges for impermeable sealing to prevent inner liquid leakage.

Ejection

Seamless sealed liquid capsules slide down collection chutes at rates up to 40,000 capsules per hour.

Inspection

Integrated monitoring validates filled volumes, ensures capsule integrity, and counts total production yield.

All these modular stations operate seamlessly through integrated automation. As a result, the machine can continually produce quality sealed liquid capsules at pharmaceutical standards.

Applications of Liquid Capsule Filling Machines

The main application of a liquid capsule filling machine is to produce sealed gelatin or vegetarian capsules. They have precise amounts of inner liquid. Moreover, they offer production of capsules at a mass scale. Some major uses across pharmaceutical, nutraceutical, and health industries include.

· Pharmaceutical Liquids

Liquid-filled capsules allow accurate dosing of viscous, oily or unstable liquid medications. Few examples include ibuprofen, fish oils, vitamin E, suspensions, and emulsions. They offer benefits over syrups. Few such benefits are taste masking, predictable dosing, and stability. Capsules also have higher patient compliance for easy swallowing.

· Dietary Supplement Oils

Machines can encase various dietary and herbal oils. They include omega fatty acids, evening primrose oil, and flaxseed oil. This shelters oxidation-prone oils from light or air exposure leading to rancidity issues. The hygienically sealed capsules have longer shelf life.

· Probiotic Cultures

Encapsulation provides protective inert shells around beneficial live bacteria cultures for regulated release internally. This helps probiotic strains survive harsh stomach acids ensuring effective intestinal delivery for gut health.

· Customized Delivery

Pharma companies leverage liquid capsules to design customized extended-release or combination products fusing ingredients needing separation. Liquids allow room for polymer matrix systems enabling sustained drug release profiles.

Overall liquid filling technology enables small-to-large scale production across diverse health products,. It offers accurate liquid volumes sealed within stable capsule delivery systems. Continued innovations further improve precision, speed, and flexibility.

Why Choose the Grand Liquid Capsule Filling Machine?

Grand is a leading global manufacturer of high-speed automatic liquid capsule fillers and ancillary equipment. Products manufactured under this brand meet the most stringent quality standards. Here are some reasons on why you should invest on a Grand liquid capsule filling machine.

· Advanced Technology

Grand invests heavily in R&D. You can see it in proprietary technologies like innovative servo-driven pumps. They come with microprocessor temperature controls for precision fill volumes within ±1% deviation. Smart systems ensure the finest quality capsules.

· Customization Options

Grand offers uniquely customizable machine configurations from semi-auto to fully automated functionality. Clients can choose capsule sizes, fill weights, electric specifications, production speeds. It is also possible to configure validations like metal detectors, and weight checkers.

· Stringent Compliances

The advanced production processes and QC protocols adhere to GMP. Hence, it meets all FDA and CE certifications. This guarantees excellence in capsule production safety, hygiene, precision, and reliability standards.

· Robust Productivity

Sophisticated PLC-controlled automation drives seamless synchronized performance. You can find it across filling, sealing, ejection modules. As a result, you can create up to 40,000 capsules per hour consistently.

· Global Experience

With an expansive international clientele from the Americas to Europe, Asia, and Australia, Grand supplies leading pharma giants manufacturing capsules across diverse markets.

· Ongoing Support

Grand provides full engineer installation support, user training, and helpful after-sales service. This ensures that the equipment continues operating optimally for years.

Conclusion

Liquid capsule filling technology enable large-scale precision production of easy-to-swallow capsules. If you are looking forward to buying a liquid capsule filling machine, always stick to a brand that you can trust. That’s where Grand L3

iquid Capsule Filling Machines would come into play. Contact us to learn more about them and order yours.