Customer visits the Pharmaceutical Packaging Line at Grand

Fish Oil Supplements: A Scientific Guide to Intake and the Secrets of Soft Gel Capsule Making Machine

The Steady Force Behind Modern Technology: The Deep Integration of Pharmaceutical Packaging Machinery and Computer Science

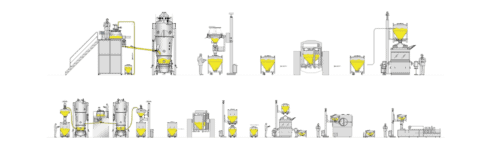

In today's rapidly evolving technological landscape, breakthroughs in Computer Science—from advanced deep learning models like deepseek, inertial navigation in unmanned measurement systems, to machine learning innovations driven by companies like Boston Dynamics—continue to captivate our imagination. Yet, while these cutting-edge developments dazzle us, the basics of our everyday lives—food, clothing, medicine, and cosmetic—still rely on the stability and reliability of equipment such as Pharmaceutical Packaging Machinery. Devices like blister machines, cartoning machines, granulators, and filling production lines operate on simple principles but deliver the robust performance necessary to keep our daily operations running safely and smoothly. The stability and efficiency of these machines are often the cornerstones of modern technology.

1. Pharmaceutical Packaging Machinery: The Unsung Heroes of Modern Life

Despite the growing public fascination with artificial intelligence and big data, Pharmaceutical Packaging Machinery remains a critical component of industrial automation, forming the backbone of production stability across various sectors.

Recent data indicate that the global pharmaceutical packaging machinery market has maintained an annual growth rate of approximately 6% to 8% over the past four years, with the Asia-Pacific region showing remarkable expansion—its market size surpassed the $15 billion mark in 2023.

This steady growth not only reflects the increasing demand for high-quality packaging equipment but also underscores the indispensable role these machines play in ensuring production safety and efficiency.

2. The Role of Computer Science in Upgrading Traditional Machinery

While the fundamental principles behind Pharmaceutical Packaging Machinery are relatively straightforward, the advent of Industry 4.0 and the widespread adoption of IoT technologies are gradually transforming the operation of traditional packaging machines.

By integrating machine learning and data analytics, manufacturers can now monitor packaging lines in real time and implement predictive maintenance strategies. For example, a recent study demonstrated that predictive maintenance schemes powered by machine learning algorithms can reduce equipment downtime by approximately 25%, significantly enhancing production efficiency and safety.

Moreover, the application of intelligent control systems and sensor technologies has enabled these machines to automatically adjust operational parameters in complex environments, ensuring consistent packaging precision and reliability.

This technology-driven innovation—fueled by advancements in Computer Science—not only reduces the need for manual intervention but also greatly improves process transparency and reliability, delivering long-term economic benefits to enterprises.

3. Data-Driven Insights: Ensuring Stability and Efficiency

An analysis of recent market data and technical reports reveals several key trends:

- Enhanced Production Efficiency: Since 2020, pharmaceutical packaging lines that have undergone smart upgrades have experienced an overall efficiency boost of approximately 18% to 22% [1].

- Reduced Maintenance Costs: The implementation of data-driven predictive maintenance has led to a 15% to 20% reduction in equipment repair costs [2].

- Improved Product Quality: The use of real-time monitoring and automatic adjustment technologies has resulted in nearly a 30% reduction in packaging defects, significantly lowering product waste and quality issues.

These insights highlight the vast potential for upgrading traditional machinery through intelligent transformation and demonstrate the crucial role of Computer Science in enhancing machine performance and ensuring product quality.

4. Looking Ahead: The Perfect Fusion of Tradition and Innovation

In the face of evolving market demands and increasingly complex production environments, the future of Pharmaceutical Packaging Machinery is poised to embrace a new paradigm characterized by "intelligence + sustainability + efficiency." With ongoing breakthroughs in Computer Science, smart packaging equipment is expected to achieve further advancements in data analytics, AI-driven control, and remote monitoring, thereby enabling full-process automation and optimization.

This evolution will not only propel the transformation of the pharmaceutical packaging machinery industry but also provide robust technical support for safe production across diverse sectors.

In summary, these seemingly ordinary packaging machines, with their stable and reliable performance, quietly underpin the smooth operation of modern society. Empowered by innovations in Computer Science, they are undergoing a renaissance that perfectly blends traditional industry with cutting-edge technology.

References

[1]T W ,T M .Safe data supply chain in the production of packaging for pharmaceutical products[J].PHARMAZEUTISCHE INDUSTRIE,2006,68(4):495-499.

[2]Yabin W ,Shuai W ,Jinguo W .Digital twin model of equipment maintenance management in modern enterprises[J].Journal of Physics: Conference Series,2021,1986(1):

2 Comments

This article deeply explores the deep integration of pharmaceutical packaging machinery and computer science, and shows how traditional industries are rejuvenated in the wave of intelligence. The article not only has detailed data and clear logic, but also vividly demonstrates the actual benefits brought by technological upgrades through case studies and market trend analysis. In particular, the discussion on predictive maintenance, intelligent control systems, and data-driven optimization makes people fully feel the transformative impact of computer science on traditional manufacturing. In addition, the article looks forward to the future development direction of intelligent packaging equipment, emphasizes the trend of “intelligence + sustainability + efficiency”, and provides forward-looking insights for the industry. Overall, this is an excellent work that is both professional and readable, and it is worth in-depth reading and thinking by industry insiders.

Do you have 4 side sealing machine with 2,5gr sachet?