DGP-A Capsule Polishing Machine – Elevating Capsule Quality in Pharma Packaging

The DGP-A Capsule Polishing Machine by Grand is purpose-built for high-quality capsule polishing. It efficiently removes surface dust, enhances capsule finish, and eliminates static electricity. Designed for all capsule types, this machine optimizes every batch for superior performance in pharmaceutical production.

Technical Specifications

| Productivity | 150,000 pcs/hour |

|---|---|

| Power Supply | 220V, 50Hz 1P |

| Machine Dimensions (LxWxH) | 1025 x 550 x 900 mm |

| Packing Dimensions (LxWxH) | 1160 x 360 x 780 mm |

| Net Weight | 34 kg |

| Gross Weight | 50 kg |

Advanced Performance Features

Efficient Dust Removal: Achieves a polished capsule surface that meets high-quality standards.

Low-Noise Operation: DC speed regulation provides robust torque while maintaining minimal noise levels.

Quick Disassembly: Fast connection and easy cleaning reduce downtime and support GMP compliance.

Seamless Integration: Equipped with a dedicated feeder, the machine links directly with Capsule Filling Machines for a smooth production process.

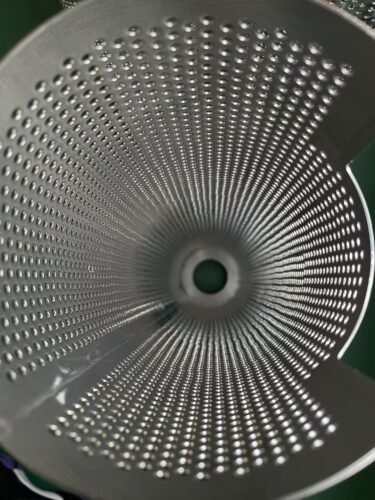

Internal mesh cylinder structure of capsule polishing machine

Built for the Pharmaceutical Industry

Constructed from premium 316L stainless steel, all drug-contact parts of the DGP-A comply with GMP standards. This ensures safety, durability, and reliability, making it an indispensable tool in modern capsule manufacturing and polishing processes.

Enhance Your Production Line

DGP-A Capsule Polishing Machine not only improves capsule appearance but also ensures a continuous, efficient workflow. Its innovative design and robust performance make it a vital component for any pharmaceutical packaging line, enhancing both product quality and operational efficiency.

FAQs About DGP-A Capsule Polishing Machine