Innovative Soft Gelatin Capsules: The Future of Delivery

9 Essential Parts of a Cartoning Machine You Didn’t Know

Chinese Medicine Soft Gelatin Capsules – In-Depth Analysis

Summary

The soft gelatin capsule, an evolving dosage form in chinese medicine production, has gradually supplanted traditional pills, powders, and ointments. With its superior bioavailability and precise packaging, the soft gelatin capsule represents a modern leap in medicine formulation. This article explores the structural features, working principles, and operating requirements of soft gelatin capsules. Drawing on the specific needs of traditional chinese medicine production, it also cites key technical references and showcases how the industry-leading Grand soft gelatin capsule manufacturing machine has revolutionized the field.

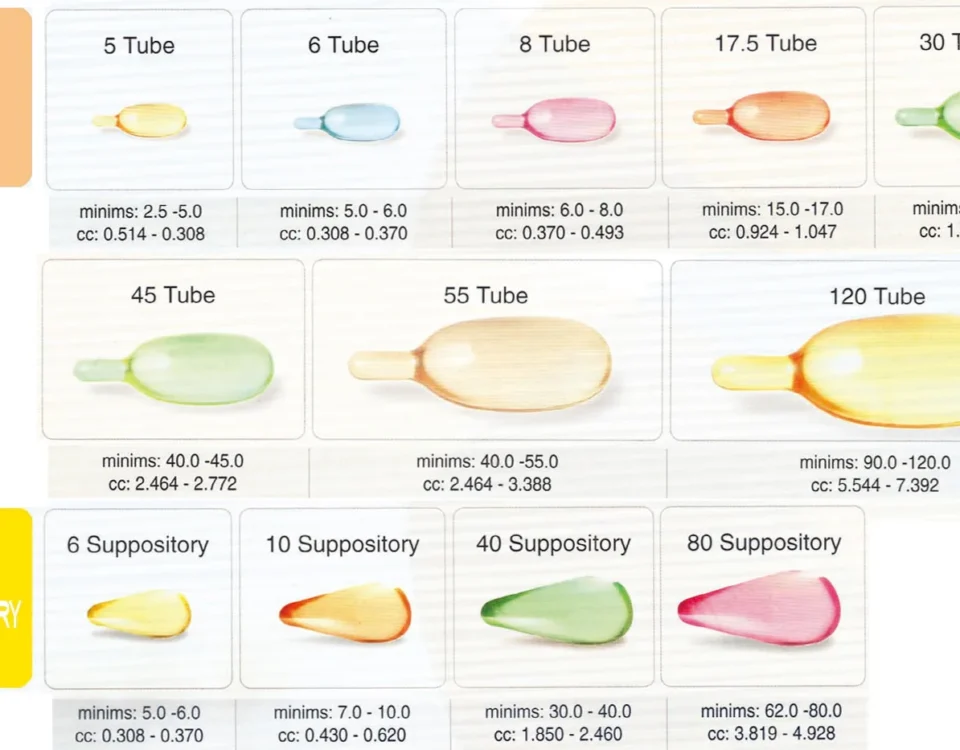

soft capsule products

Structural Features of Soft Gelatin Capsules

Soft gelatin capsules are created by sealing medicinal extracts or finished products with suitable excipients inside a soft, flexible shell. Unlike hard capsules, these innovative formulations are produced using advanced equipment that integrates precise engineering with high-quality materials.

The structure of soft gelatin capsules consists primarily of three parts:

Precision Shell Formation

Modern production uses advanced machinery—such as the rotary soft gelatin capsule manufacturing machine—to shape the capsule shell. The equipment comprises a base frame, main body, feeding system, oil roller system, and a pellet ejector. As the liquid gelatin is evenly applied on the roller surfaces, it forms a uniform film that is rapidly cooled and solidified. This process ensures the capsules are well sealed and consistent in thickness, greatly enhancing the quality of soft gelatin capsules.Automated Control Benefits

Contemporary equipment features PLC control systems to automatically regulate temperature, flow, and pressure. Integrated sensors and heating elements precisely control the gelatin temperature. This automation leads to uniform viscosity and consistency throughout the production run. With minimal manual intervention, the system guarantees stable output and prolonged equipment service life—critical benefits for both traditional chinese medicine and eastern medicine markets.Modular Design for Efficiency

The rotary soft gelatin capsule machines are designed with modularity in mind. Key units like the main machine, conveyor, dryer, and electrical cabinet work seamlessly together. The modular design of the gelatin and raw material tanks allows for easier cleaning, maintenance, and multi-step operations. This innovative approach ensures that the production line meets stringent GMP (Good Manufacturing Practice) standards, making it ideal equipment for manufacturers using chinese herbs.Compliance with GMP Standards

Maintaining hygiene and safety is crucial in the production of chinese medicine formulations. Soft gelatin capsule production equipment is constructed from high-grade stainless steel with automated cleaning features. This greatly reduces the risk of cross-contamination, thereby ensuring that each soft gelatin capsule meets international pharmaceutical standards.

Grand highly automated soft gelatin capsule making machine

In-Depth Analysis of the Working Principle

The production of soft gelatin capsules is based on rotary compression technology. The process begins with a precisely balanced mixture of medicinal extracts and excipients, which is then heated, stirred, and fed into the machine. This method ensures that the active ingredients are evenly distributed within the capsule and that each capsule is produced with remarkable consistency.

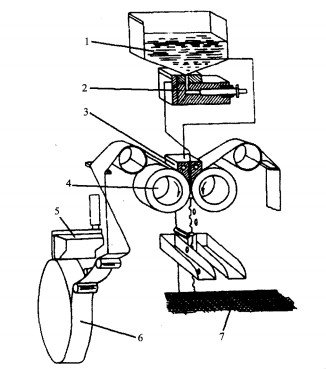

Working principle diagram of soft capsule pressing machine

Synchronized Feeding and Molding Process

The operation begins when a precisely mixed chinese medicine solution is fed into the rotary machine. After heating and thorough mixing, the liquid is metered out by the feed pump into a preformed gelatin pouch. Two rotating molds align accurately via micro-adjustments so that when the liquid is injected, it is evenly compressed into a capsule form. This synchronization of injection and molding is critical for ensuring the perfect seal and uniform capsule weight in every batch of soft gelatin capsules.Cooling and Stabilization Through Drying

Once formed, the soft capsules are directed onto a conveyor that leads them into a specialized drying unit. This dryer, often made of stainless steel wire baskets and equipped with a purified airflow system, rapidly cools the capsules to stabilize their shape. A subsequent secondary drying stage ensures that the capsules achieve the optimal hardness and stability before packaging. This process is especially essential in chinese medicine production where the balance and absorption of active ingredients directly affect the therapeutic effects.

V-type mixer required in the production of Chinese herbal medicine

Real-Time Monitoring and Automatic Feedback

Integrated control systems monitor the entire production process in real time. Temperature sensors, flow meters, and pressure gauges feed continuous data back to the central PLC system. Any deviation—whether from fluctuations in capsule film thickness or inconsistencies in the medicinal fill—is immediately adjusted by the equipment. This automated feedback loop is an essential advantage for consistent quality, ensuring that every soft gelatin capsule meets the strict standards demanded by the chinese medicine industry.

Operating Requirements and Specific Considerations for Chinese Medicine Production

Efficient operation of soft gelatin capsule production equipment is critical to achieving high-quality outputs, especially when dealing with the complexities of chinese medicine. Detailed operating procedures must be followed to ensure that the equipment delivers optimal performance.

Strict Pre-treatment and Ratio Control

All ingredients, such as gelatin, water, glycerin, and additional excipients, must be pre-measured accurately. The mixture must be heated to 80–90℃ and stirred thoroughly to obtain a homogeneous solution. For products containing chinese herbs, adjustments in the formulation may be necessary to account for variations in herb concentration. Precise ratios are imperative to maintain the unique properties of both traditional chinese medicine and eastern medicine products.Preheat and Cleaning Procedures

Before operation begins, thorough cleaning of the main machine, feeding lines, gelatin boxes, and storage tanks is crucial. Residual medicinal material can cause blockages and cross-contamination if not properly rinsed out. Special attention must be given to removing residues from low-melting-point compounds and sugar-rich formulations. Maintaining equipment cleanliness not only prolongs the service life of the production equipment but also supports the consistent quality of the soft gelatin capsules.Environmental Control for Optimal Operation

The production area must be maintained under strict environmental conditions. During capsule compression, the ambient temperature should be between 18–22℃, with relative humidity ranging from 40%–55%. For the drying phase, the temperature should remain below 30℃ with relative humidity controlled between 20%–35%. These conditions are particularly important for chinese medicine products, where precise temperature and humidity control ensure the stability of active ingredients from chinese herbs.Fine-Tuning and Quality Control

Operators must continually monitor capsule film thickness and fill weight using onboard gauges and precision scales. As soon as a deviation is observed, micro-adjustments to the feed pump speed and injector stroke should be made. Frequent sampling and weight measurements guarantee that each soft gelatin capsule meets the exacting standards required for both chinese medicine and modern pharmaceutical applications. This meticulous level of quality control is instrumental in reinforcing the reputation of traditional chinese medicine products in global markets.

Grand Soft Gelatin Capsule Manufacturing Machine: An Industry Benchmark

Among the many systems available, the Grand soft gelatin capsule manufacturing machine stands out as a leader in the industry. With advanced technology and robust performance, Grand equipment has set new benchmarks in production quality and efficiency.

High-Performance Production Capability

The Grand machine excels in precise dosing, uniform injection, and rapid molding. Its stable operation is particularly suited to the rigorous demands of chinese medicine production, where consistency and safety are paramount for both traditional chinese medicine and eastern medicine products. Manufacturers can rely on this equipment to process even the most challenging ingredients, including delicate chinese herbs.

Integrated Automatic Monitoring and Alerts

Featuring a comprehensive PLC system combined with a network of sensors, the Grand machine continuously monitors every parameter throughout the production run. In cases of minor anomalies—such as slight changes in viscosity or capsule thickness—the system automatically adjusts settings and alerts operators. This intelligent monitoring not only minimizes downtime but also ensures that every capsule is produced to exact specifications.Versatility Across Diverse Product Lines

The Grand soft gelatin capsule machine is engineered to adapt to a wide variety of products. Whether producing capsules for modern chinese medicine formulations or catering to niche products in traditional chinese medicine and eastern medicine, this versatile equipment can be configured to meet diverse production requirements. Its flexibility makes it a preferred choice for companies aiming to upgrade their production lines with high-quality equipment.Outstanding Technical Support and Service

Beyond its technical prowess, Grand is known for its exceptional customer support. The company offers comprehensive training, setup assistance, and continuous technical support, ensuring that manufacturers can maximize the performance and lifespan of their machines. Such dedicated service fortifies the reputation of Grand equipment as a trusted tool in the highly competitive field of soft gelatin capsule production.

Conclusion

Soft gelatin capsules have become an essential dosage form in modern chinese medicine, offering improved bioavailability and precision over traditional methods. This article has delved into the structural features, working principles, and operating requirements of soft gelatin capsule production systems. By addressing the specific needs of chinese medicine production—whether related to traditional chinese medicine techniques or broader eastern medicine practices—manufacturers can achieve superior product quality using state-of-the-art equipment.

The Grand soft gelatin capsule manufacturing machine exemplifies the industry's cutting edge, providing reliable performance, precise control, and robust adaptability for processing chinese herbs and other vital ingredients. As the global market for soft gelatin capsules continues to expand, manufacturers that invest in advanced, automated equipment are well-positioned to meet growing demand while ensuring top-notch product quality. Embracing such innovation is key to advancing both traditional practices and modern pharmaceutical technologies, ensuring that chinese medicine remains a vibrant and effective field in the 21st century.