Automatic Checkweigher for Small Packages

GCW100-A automatic checkweigher delivers ±0.02g precision at 120 PC/min. Ideal for food, pharma & more.

Automatic Checkweigher Series

Looking to ensure precision, quality, and efficiency in your production line? The Grand GCW100-A Automatic Checkweigher is engineered for high-speed, high-accuracy weight inspection of small packaged goods. With a compact design and smart software integration, this checkweigher offers unmatched reliability in dynamic industrial environments.

Built for integration with high-speed single-lane packaging machines(High Speed Blister Packaging Machine), and optional auto-feedback functionality, the GCW100-A not only maintains product weight accuracy but also actively contributes to lowering waste, optimizing fill volumes, and reducing energy consumption.

Whether you operate in the pharmaceutical, food, personal care, toy, or hardware industry, this checkweigher is your go-to solution for dependable weight verification and sorting.

Applications

Pharmaceuticals – Capsule, tablet, and blister pack weight validation

Food Processing – Candy, snack packs, sauces, powders

Cosmetics & Personal Care – Cream tubes, sachets, face masks

Hardware & Tools – Small parts and fittings

Toys & Hobby Items – Bags of mini parts, kits

Perfectly suited for high-throughput production lines, the GCW100-A handles up to 120 products per minute without compromising on precision.

Key Features of the GCW100-A Checkweigher

✅ High Accuracy Weighing

Precision up to ±0.02g, ensuring that every product leaving your line meets stringent weight standards.

✅ Compact, Space-Saving Design

Small footprint allows easy integration into limited spaces or mobile use across multiple lines.

✅ Stable and Reliable Operation

Proprietary structure minimizes external interference, maximizing detection stability even in demanding environments.

✅ Smart Recipe Management

Store up to 100 recipes. USB export capability supports quick data retrieval and product switching.

✅ GMP Compliant

Designed for cleanroom compatibility. Tool-free dismantling and easy-to-clean components ensure compliance and hygiene.

✅ User-Friendly Interface

Multi-language support and intuitive controls reduce training time and human error. One-touch operations for fast setup.

✅ Sensor Overload Protection

Custom overload mechanism protects internal load cells from accidental heavy impacts—preserving performance and lifespan.

Why Choose Grand Checkweigher?

🔹 Decades of Engineering Excellence

With years of experience in industrial automation, Grand delivers trusted weighing solutions to factories around the world.

🔹 Customizable Solutions

Need a special dimension or configuration? We offer tailor-made checkweighing systems to suit unique production needs.

🔹 Fast ROI

Reduce product give-away, cut down on rework, and maintain consistent quality—improving your bottom line in no time.

🔹 Scalable for Growth

As your business scales, so can our machines. From small batch processing to full automation lines, Grand grows with you.

🔹 Global Support Network

Need help? Our professional sales and technical teams provide fast, responsive service wherever you are.

Specifications

| Model: GCW100-A | |

|---|---|

| Weighing Range | 0.2 – 200g |

| Accuracy | ±0.02g / ±0.05g |

| Max Throughput | 120 PC/Min |

| Weighing Type | Belt-driven |

| Sorting Mode | Forward & Reverse |

| USB Export | Supported |

| Power Supply | 220VAC, 50/60Hz, ≤1.5A |

| Note: Custom sizes and configurations available upon request. | |

Machine Details

Checkweigher-display

GCW100-A side details

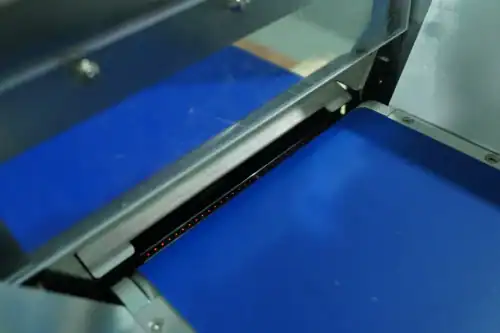

GCW100-A Belt Details

FAQs About Checkweigher Machines

1. What is the purpose of a checkweigher machine?

A checkweigher machine is used to automatically verify the weight of products on a production line. It ensures that each item meets weight specifications, helping manufacturers maintain quality control, reduce product giveaway, and comply with industry regulations.

2. How accurate is a checkweigher machine?

Checkweigher machines like the GCW100-A can achieve high precision levels, with accuracy up to ±0.02g. The actual accuracy depends on the product type, speed, and environmental factors. Proper calibration and setup ensure optimal performance.

3. Can checkweighers be used for small packages?

Yes, many checkweigher machines are specifically designed for small package applications. The GCW100-A, for example, supports a weight range from 0.2g to 200g and is ideal for pharmaceuticals, snacks, cosmetics, and hardware items.

4. What industries use checkweigher machines?

Checkweigher machines are widely used in the food, pharmaceutical, cosmetic, hardware, and toy industries. Any manufacturing process that involves packaging by weight can benefit from using a checkweigher to ensure consistency and avoid underfilling or overfilling.

5. Do checkweighers store product data?

Advanced checkweighers like the GCW100-A offer USB data export and can store up to 100 recipes and 300,000 weight records. This makes it easy to track production history, perform audits, and meet traceability standards.

6. How does a checkweigher machine work in a production line?

A checkweigher machine integrates into a conveyor system. As products pass over the weighing platform, the machine measures each item’s weight in real time. Items outside the acceptable range are automatically sorted out or flagged for rejection, ensuring only in-spec products proceed down the line.

Contact Us