Why Are Gummies Acidic? The Tangy Truth About Gummy Candy

Why Start Your Own Nutritional Supplement Business?

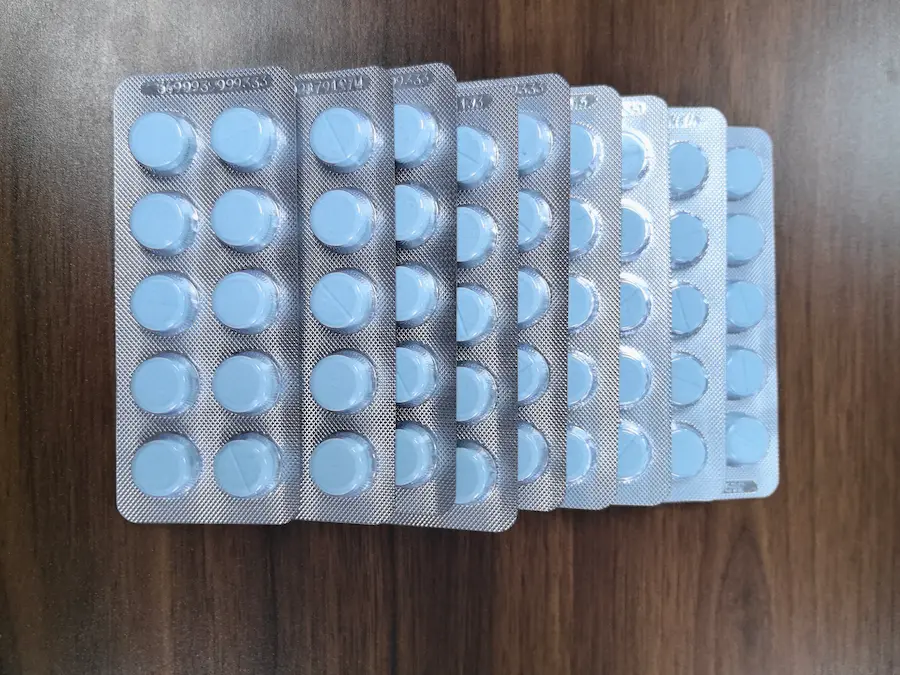

Tadalafil Blister Packaging: Grand’s DPP-180L Alu-Alu Machine Solutions

Introduction

Tadalafil tablets demand careful packaging to ensure product stability and patient safety. Blister packaging is a preferred solution for pharmaceuticals like Tadalafil, offering a sealed barrier against moisture and contamination.

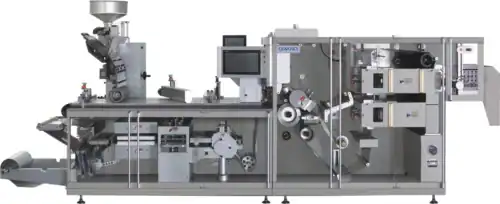

Grand Packaging Machinery’s advanced blister packaging systems – notably the DPP-180L automatic alu-alu blister packaging machine – excel in packing Tadalafil and other tablets in high-quality blister packs. In the pharmaceutical industry, terms like blister pack, blister package, and blister packaging are often used interchangeably (in German, Blisterverpackung).

They refer to pre-formed cavities that hold tablets or capsules, typically sealed with foil or film. Grand’s machines handle blister cards, blister boxes, blister bags or trays – any common blister package format used for tablets and capsules. By using Grand’s automated blister packaging machinery, companies can efficiently produce compliant alu-alu blister packs that maintain drug quality.

Grand’s DPP-180L automatic blister packaging machine in operation, illustrating the high-speed packaging of pharmaceutical tablets into alu-alu blister packs. Machine is ISO 9001, GMP, and CE certified (logos visible).

Grand’s blister pack machines support multiple materials and styles. For example, the DPP-180L can form and seal Alu/PVC, paper/Alu, and Alu/Alu blisters for capsules or tablets. In practice, Grand’s equipment packages Tadalafil tablets in precise thermoformed cavities, then seals them under aluminum foil (alu-alu), creating a blister card that protects each dose.

This blister packaging approach is favored by many pharmaceutical companies, as evidenced by regulatory data: FDA filings for a tadalafil-containing drug report a 24‑month shelf-life for tablets stored in sealed blister packs. In other words, blister packaging is proven to maintain tadalafil tablet stability over time. Tadalafil and other sensitive compounds need the moisture and oxygen barrier that alu-alu blister packs provide. Grand’s alu blister machine design – with positive-pressure forming and high-precision sealing – ensures uniform cavities and tight seals, which is crucial for protecting hygroscopic tablets.

Why Blister Packaging Matters for Tadalafil and Other Drugs

Blister packaging offers clear advantages for pharmaceutical products like Tadalafil. By enclosing each tablet in an individual pocket sealed by foil, blister packaging gives tamper evidence and dosage accuracy. Compared to bulk bottles or sachets, blister packs reduce the risk of contamination and mix-ups. The high barrier properties of aluminum foil (Alu-Alu) protect Tadalafil tablets from moisture and light. For instance, European drug labels for Cialis (tadalafil) note that the film-coated tablets are supplied in alu/PVC or alu/alu blisters. The FDA review of a tadalafil combination product explicitly states a 24-month shelf-life for tablets in blister packs, underscoring the effectiveness of blister pack storage. In many markets, healthcare regulations and GMP guidelines also favor blister pack formats for solid oral dosage forms.

Blister packaging can take many terms: “blister pack” or “blister package” (English), Blisterverpackung (German), and even occasional typos like “blist pack” or “blister packagin” in search queries. They all refer to the same concept of a tray of cavities bonded to a backing (foil or film). The blister card or carded blister often mounts on a cardboard backing, while a blister box can hold multiple blister cards. A blister bag might refer to a baggie containing blister strips. Regardless of format, the key is that blister packaging isolates tablets individually. Grand’s DPP-180L supports these forms by outputting blister strip rolls or cut strips that fit into boxes or bags as needed.

For manufacturers, investing in a blister packaging sealing machine is crucial. A modern blister packaging machinery line includes film unwinders, forming stations, filling stations, sealing presses, batch code printers, and cutoff cutters. Grand’s equipment integrates all these steps. As a blister pack machine, it automates tablet placement into cavities and the blister packaging sealing machine portion heats and presses the foil to seal each pocket. The result is a continuous line producing blister packs ready for inspection and cartoning.

In markets where China is a leading supplier of pharmaceutical equipment, Grand is one of the top providers of blister packing machines in China. Its technology is comparable to global standards. Notably, Grand offers machines in various sizes – from small blister pack machines for low-volume production to its large-scale DPP-180L line. For example, Grand’s smaller models can run a few thousand tablets per hour for smaller factories, while the DPP-180L can exceed 10,000 tablets/hour for big pharmaceutical plants.

Grand’s Advanced Blister Packaging Machinery

Grand Packaging Machinery Co., Ltd. has been a specialist in pharmaceutical and packaging equipment for nearly 20 years. The company emphasizes quality and innovation. On its official website and product pages, Grand highlights certifications (ISO 9001, CE, GMP) and its comprehensive product line. Grand’s machines are exported worldwide – the company reports installing packaging lines in many countries across Asia, Europe, the Americas and beyond. For example, Grand has supplied blister packing machines to clients in Indonesia, Thailand, Malaysia, the Middle East, Europe (Poland, Belgium, France, Greece, Italy, UK) and the Americas (Trinidad & Tobago, Mexico, Brazil). This global presence reflects strong market influence and customer trust.

The DPP-180L Automatic Alu-Alu Blister Packing Machine represents Grand’s top-of-line blister machine. As described on Grand’s site, this model is a “pharmaceutical packaging machine innovatively designed by our company” with “functions [that] have reached the domestic advanced level”. In plain terms, it is engineered for high-speed, fully automated blister packaging. Key features include:

Multi-material support: The DPP-180L handles Alu/Alu foil, Alu/PVC film, and paper/Alu combinations, making it versatile for different products. It can package capsules, tablets, candies, syringes and even special-shaped items in blister form. This versatility means a single machine can pack various tablet or capsule packaging needs.

Automation and control: It uses PLC/microcomputer control with frequency conversion speed regulation and a touch-screen interface. This high degree of automation means the machine can run continuously with minimal operator intervention, adjusting speed dynamically. The integrated system performs film unwinding, blister thermoforming, tablet filling, foil feeding, heat sealing, date/batch coding, and die-cutting in one flow.

High performance: With up to 40 punches per minute (depending on blister size), it achieves production of roughly 4–8 × 10,000 capsules per hour. Such throughput is suitable for large-scale pharmaceutical manufacturing.

Deep forming and uniform seals: Grand’s double-rod pendulum forming system provides up to 180mm stroke, enabling deep cavity forming for larger tablets and specialty products. The machine uses positive-pressure forming and precise die-cut punching to ensure each blister has a uniform depth and shape. Uniform forming is critical for consistent tablet fit and foil sealing.

Precision sealing: The heat-sealing station applies controlled pressure and temperature (with quick-change molds) to bond the Alu-alu foil onto the blister cavities【25†】. This provides hermetic seals that protect Tadalafil’s potency. The DPP-180L even includes automatic batch number printing and embossing in-line.

Modular, service-friendly design: Grand’s machines feature a split-frame assembly, meaning the heavy body is shipped in sections and assembled on-site for easier transport. Molds (for forming, sealing, cutting) use quick-connect fixtures, reducing changeover time. The main drive uses parallel-shaft bevel gear reducers for accuracy and durability. All moving parts are within guarded compartments, and optional windows allow the operator to monitor processes.

Safety and compliance: Built for the pharmaceutical environment, the machine can be enclosed with acrylic covers, and optional photocells ensure jam-free operation. Grand machines meet CE and ISO certifications (see visible logos in Figure) and comply with cGMP standards.

When packaging Tadalafil tablets, these features translate to reliable, fast production of blister strips or blister box inserts. For instance, Grand often recommends alu-alu sealing for Tadalafil and similar moisture-sensitive drugs. In practice, a Tadalafil factory would load bulk tablets into the DPP-180L’s feeder, and the machine would dispense them into the formed cavities. After sealing and coding, each blister pack is precisely cut into single or multi-blister cards. These cards can be counted, bagged, or placed in blister boxes as final packages.

Beyond blister packs, Grand provides related equipment (tablet presses, capsule fillers, cartoners) to offer end-to-end lines. But the blister packing machines are its hallmark tablet packaging machines. The “blister packaging sealing machine” function is part of this integrated line, and Grand also sells standalone sealing presses.

Product Quality and Customer Cases

Quality assurance is central to Grand’s brand. The company notes that its products have passed ISO 9001 and CE certifications (and numerous customer audits). These quality marks assure pharmaceutical clients that the blister pack machines meet international safety standards. Grand also offers full documentation – machine qualifications (IQ/OQ/PQ support) and packaging material validation advice.

Real-world customer experiences back up Grand’s claims. For example, a Vietnamese pharmaceutical firm purchased Grand equipment in 2017 (including a blister packaging machine). Eight years later, that blister machine continues running stably and efficiently. The customer explicitly praised Grand’s after-sales service, saying that regular support and timely parts were the “foundation for [the machines’] long-term reliability”. This Vietnamese client even referred peers to Grand, impressed by the blister machine’s durable performance. Such testimonials highlight that Grand’s blister packs retain performance over many years, providing value far beyond initial purchase.

Another case: A dental needle manufacturer in Turkey bought a Grand DPP-80 blister packing machine eight years ago and reports it still works reliably today. That client specifically said the machine’s durability and stable output convinced them of Grand’s quality (described in a Grand blog). Though this case involves needles, the lesson applies to tablets like Tadalafil: a well-made blister machine will remain productive and compliant long-term.

Grand’s market influence is also evident in its global reach. The company reports supplying machines to over 30 countries. Its users range from large pharmaceutical corporations to regional generics manufacturers. Many customers work with Grand on other projects (capsule fillers, cartoners, etc.), reflecting satisfaction with the brand. Grand has over 350 customers and exports to 160+ countries (per company data). The company’s international offices and multilingual support (English, Spanish, Arabic, Russian, etc.) help overseas clients integrate blister lines smoothly. For procurement managers, knowing that Grand machines run worldwide and have a track record is reassuring.

Conclusion

In summary, Grand’s blister packaging technology – especially the DPP-180L alu-alu blister machine – is well-suited to packaging Tadalafil and other pharma tablets. Grand’s machines offer high-speed, automated forming, filling, and sealing of blister packs, meeting GMP standards.

Key technical advantages (deep forming, precise sealing, modular design, multilingual controls) result in reliable, high-throughput packaging lines. Real customer feedback and broad global sales attest to Grand’s quality and service. Pharmaceutical companies seeking blister packaging solutions (for blister packs, blister boxes, or blister cards of Tadalafil or similar products) should consider Grand’s machines. The combination of advanced machinery and strong after-sales support is designed to ensure that tablets remain safe and drugs remain effective up through delivery to patients.